What Is A Volumetric Cup Filler Machine?

What is Volumetric Cup Filler Machine All About?

First things first, let's break down what a volumetric cup filler machine is all about. This volumetric cup filler is all about measuring the right amount of products to put into containers. It's perfect for small granule and powder because it measures by volume instead of weight, ensuring each container gets just the right amount of whatever you're pouring.

Volumetric Filling Machine Working Principle

Imagine filling a cup with rice: if you fully fill it the same way each time, the weight stays consistent. That's how a volumetric filling machine works.

How Volumetric Cup Filler Works

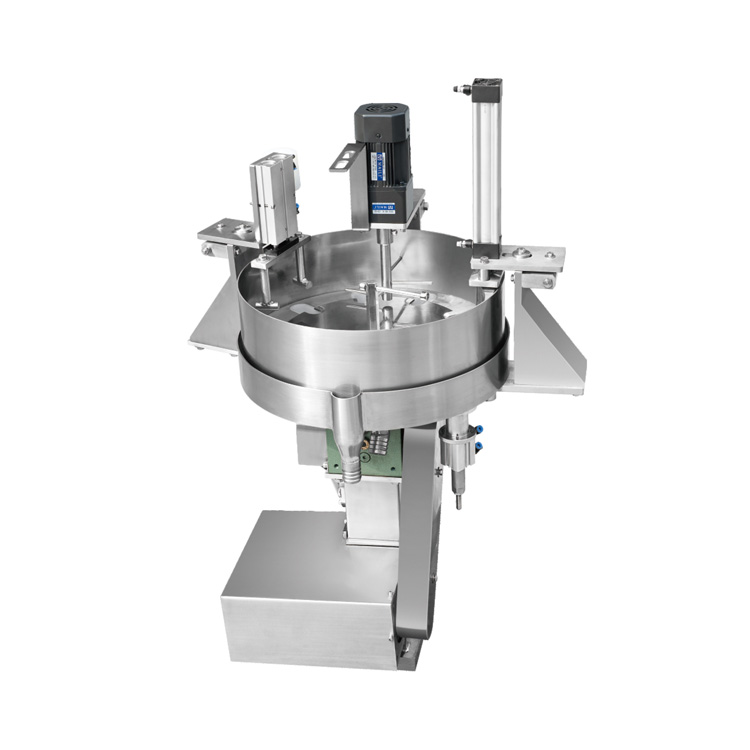

It has multiple cups in a storage hopper, each scooping up and measuring a precise amount of product.

As the machine operates, your free flowing products drop into the cups, and as they rotate to the top of the cycle, a mechanism levels off the contents to ensure each cup is filled to the exact same volume. This process is key to maintaining consistency – just like when you fill your cup of rice to the brim every time.

Once the cups are filled and leveled, they reach the dispensing point. Here, the volumetric filling machine releases the contents into waiting containers, bags, or packaging units below. This cycle repeats rapidly, allowing for high-speed filling without sacrificing the accuracy or consistency of the product volume.

Measuring Cup Filling Machines With VFFS

The top partner of the volumetric filling machine is the vertical form fill machine, a dynamic duo in the packaging industry. This combination enhances the efficiency and scope of packaging operations, offering a complete solution from filling to packaging for dry free flowing products.

The vertical form fill machine complements the volumetric cup filler by taking the accurately measured product and seamlessly packaging it. Here's how they work together:

Integrated Packaging Process: After the volumetric cup filler measures and dispenses the product, the vertical form fill machine takes over. It forms pouches or bags from rolls of flat film, fills them with the product, and then seals them. This streamlined process from filling to packaging is efficient and time-saving.

What's really neat about this system is its versatility. You can adjust the volume of the cups to suit different products or packaging sizes. This means the same machine can be used for a variety of products, simply by tweaking the settings. It's a one-size-fits-all solution that's perfect for industries where product variety is the norm.

Moreover, the machine's design often includes features like an agitator in the hopper. This agitator keeps the product from settling and clumping, ensuring a smooth flow into the cups and consistent volume every time. It's these thoughtful details that make the volumetric cup filler not just a machine, but a reliable part of the production line.

In essence, the volumetric cup filler machine is all about precision, efficiency, and adaptability. Whether you're packaging food, pharmaceuticals, or industrial goods, it ensures that each product is filled to the exact volume required, quickly and consistently. It's a simple concept – much like filling a cup of rice – but executed in a way that transforms the efficiency of production lines across various industries.

Features of Volumetric Cup Fillers Packaging Machine

The volumetric filling machine's versatility is a big plus. You can adjust the cup sizes for different products, making it a flexible solution for various industries.

Easy to Operate

One of the standout benefits of a volumetric cup filling machine encompass a user-friendly control panel designed for ease of use, along with pneumatic controls that reduce the need for operators to physically handle the product during filling. Furthermore, numerous machines come equipped with built-in maintenance services, ensuring minimal downtime and consistent, smooth operation.

Enhanced Speed and Accuracy

The synergy between the volumetric cup filler and the vertical form fill machine significantly boosts both speed and accuracy in the packaging process, making this combination a powerhouse in production efficiency.

Cost-Effective Solution

By integrating the filling and packaging processes, this pairing reduces the need for additional equipment and labor, offering a economical alternative solution for businesses.

Consistent Quality Control

The combination ensures consistent quality in both the volume of the product filled and the integrity of the packaging, maintaining high standards throughout the production line.

Space Efficiency

This combination is space-efficient, as the vertical form fill machine vertically aligns the packaging process, saving valuable floor space in manufacturing facilities.

In short, the volumetric cup filling machine is all about precision and efficiency, perfect for packaging a wide range of products consistently and quickly.

How to Choose the Best One

When you're looking for one of these volumetric filling machines, think about:

* What you're filling (size and texture).

* How fast and how much you need to fill.

* How it'll work with your current setup.

* How easy it is to take care of and clean.

Other Filling Machines

Beyond the volumetric cup filling machine, the world of packaging machinery offers a diverse array of filling machines, each tailored to meet specific needs and challenges in the production line. Understanding these alternatives can help businesses choose the right equipment for their unique requirements.

Multihead Weighers

For businesses focusing on boosting their production line, the multihead weighing machine is a standout choice. It excels in weighing, filling products with speed and precision, thanks to its adjustable gravity flow function and the option to add different nozzles for various products. Key features to look for include an adjustable fill rate, user-friendly control panel, compact design, durable construction, and affordability. This machine is not just a tool but an investment in enhancing your production efficiency.

Powder Filling Machine

A powder filling machine is an essential tool for handling powdery substances. It typically consists of a hopper that channels the powder into a container through a tube. This machine is designed to dispense the correct amount of powder consistently, making it a staple in industries like food, pharmaceuticals, and chemicals. Its ability to fill a range of container sizes accurately and quickly, coupled with its straightforward operation and low maintenance, makes it a valuable asset.

Pump Filling Machine

This type of machine, including the popular peristaltic pump model, is ideal for filling viscous products like sauces and lotions. The positive displacement pump offers precise control over the product flow, ensuring accuracy and reliability in filling. These machines are less expensive than other types and are widely used in food and beverage production, personal care manufacturing, and pharmaceutical manufacturing for filling a range of products into bottles, jars, tubes, or blister packs.

Capsule Filling Machine

The capsule filling machine, particularly useful in pharmaceutical and health product industries, is designed for filling empty capsules and tablets. It's a fully automatic machine that leverages advanced PLC technology for simple, efficient operation. Its versatility allows for filling various capsule sizes and types, making it a multi-faceted tool for small to medium-sized enterprises, health care product factories, and Chinese herbal medicine manufacturers.

Each of these filling machines brings unique advantages to the table, catering to different aspects of the packaging process. From handling powdery substances to filling viscous liquids, these machines enhance efficiency, accuracy, and productivity in various industrial settings. Understanding their capabilities allows businesses to make informed decisions when expanding or upgrading their packaging equipment.

Final Thoughts

In wrapping up, the volumetric cup filler machine stands out as a true workhorse in the packaging and production industry. Its precision in measuring and dispensing products, especially small granules and powders, revolutionizes how businesses approach packaging. If you're looking for a quality machine that will help improve your production, Smart Weigh is a reputable and trusted company, offering high-quality volumetric cup filler machine at your disposal!

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine