What is Pouch Packing Machine?

Nowadays, the majority of businesses are looking for methods to cut costs and boost productivity in order to raise profit margins. Food manufacturers also seek to reduce labor and machinery costs while increasing production efficiency when they produce a range of food types, including granular products (snacks, nuts, jerky, dried fruits, candies, chewing gum, pistachios, meat), powders (milk powder, flour, coffee powder, glucose) and liquids.

With just one machine, organizations can meet all of their packaging needs and avoid additional machinery costs thanks to the Pouch Packaging Machine's effective packaging range. A variety of packing options are available with the Pouch packing Machine. It can package granules, powders, liquids, pastes, and irregular shape materials by using different measuring equipment.

The machine is adaptable to a wide range of packaging bags, suitable for multi-layer composite film, aluminum foil, single-layer PE, PP, and other materials used in premade bags and paper bags. It uses premade packaging bags, resulting in low material loss, perfect pouch patterns, and high-quality sealing; it's also versatile for multiple uses.

As the name suggests, pouch packing machine is a type of packaging machine used in various industries for packaging products in premade pouches. It's designed to automatically pick up, open, fill and seal pouches with a variety of products, ranging from liquids and powders to solids and granules.

At Smart Weigh, you could find pouch packaging machine from small-scale operations to large and industrial production, each type of machine is designed to meet specific packaging needs.

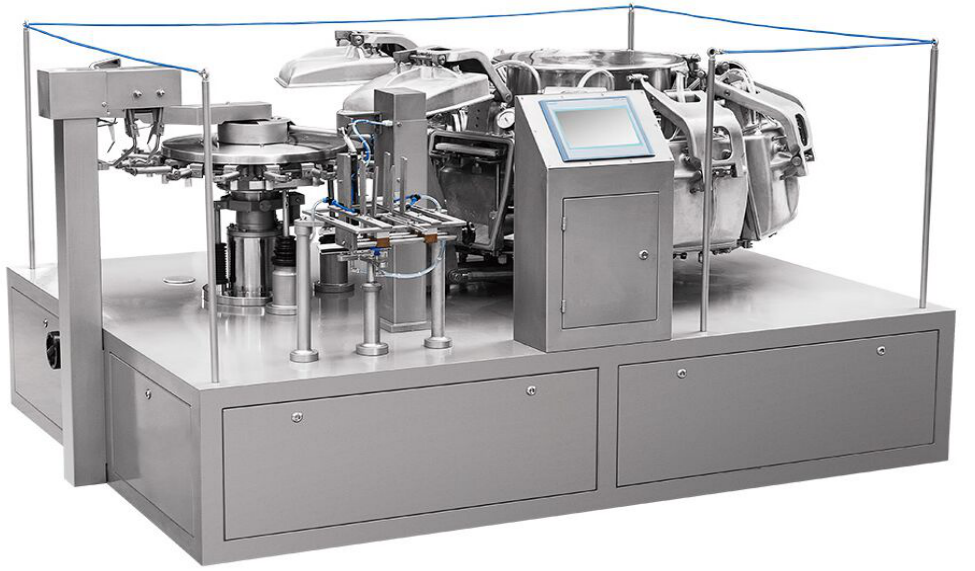

Rotary Pouch Packing Machine

Rotary pouch packing machines are known for their efficiency and versatility. They operate by rotating a carousel where multiple pouches can be filled and sealed simultaneously. This type of machine is ideal for a variety of products, including liquids, powders, and granules. Its high-speed operation makes it suitable for large-scale production environments where time and efficiency are crucial.

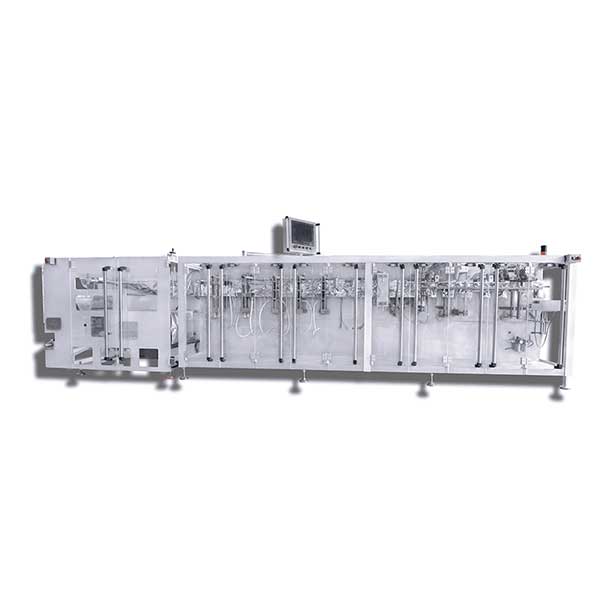

Horizontal Pouch Packing Machine

Horizontal pouch packing machines are designed for easy operation and maintenance. They are particularly effective for packaging flat or relatively flat products. The horizontal layout allows for easy loading of products and is often used for larger, bulkier items. These machines are known for their gentle handling of the product, making them ideal for fragile or irregularly shaped items.

Mini Pouch Packing Machine

Mini pouch packing machines are the perfect solution for small-scale operations or businesses that require flexibility with limited space. Despite their compact size, these machines offer a range of functions, including filling, sealing, and sometimes printing. They are ideal for startups or small businesses that need efficient packaging solutions without the large footprint of industrial machines.

Vacuum Pouch Packing Machine

Vacuum pouch packing machines are designed to extend the shelf life of products by removing air from the pouch before sealing. This type of machine is essential for packaging food products like meats, cheeses, and other perishables. By creating a vacuum inside the pouch, these machines help in preserving the freshness and quality of the product, making them a popular choice in the food industry.

Horizontal Form Fill Seal Machine

Horizontal form-fill-seal (HFFS) machines are popular in Europe as they are highly efficient for creating premade pouches from rolls of flat film. They fill and seal these pouches in a continuous horizontal process. HFFS machines are commonly used in the food industry for packaging snacks, confectionery, cosmetics, and other small items.

Vertical Pouch Packing Machine

Vertical pouch packing machine, it has another name called vertical form fill seal machine, which is forming pillow bags, gusset pouches, quad bags from a roll of film, filling them with product, and then sealing them, all in a vertical fashion efficiency.

Are you looking for an efficient and reliable solution to your packaging needs? As a pouch packing machine manufacturer with more than 10 years experience, we not only provide single machines but also offer comprehensive packaging systems customized to your exact specifications.

Linear Weigher Pouch Packing Machine

The Linear Weigher Pouch Packing Machine is renowned for its small compact design and simplicity. It's particularly suited for granular and free-flowing products like sugar, salt, rice, and grains. This machine uses linear weighers to dispense the right amount of product into each pouch. It's an ideal choice for start-up businesses looking for a cost-effective, yet precise, weighing and packaging solution.

Multihead Weigher Pouch Packaging Machine

The Multihead Weigher Pouch Packaging Machine is a step up in terms of speed and efficiency. It's perfect for a variety of products, including snacks, frozen foods, and candies. This machine uses multiple weigh heads to quickly and accurately measure portions, significantly speeding up the packaging process while maintaining accuracy.

Auger Filler Pouch Packaging Machine

The Auger Filler Pouch Packaging Machine is specifically designed for handling powdery and fine-grained products like flour, spices, and milk powder. It uses an auger or screw mechanism to dispense the product into pouches, ensuring precise portion control and minimal product wastage.

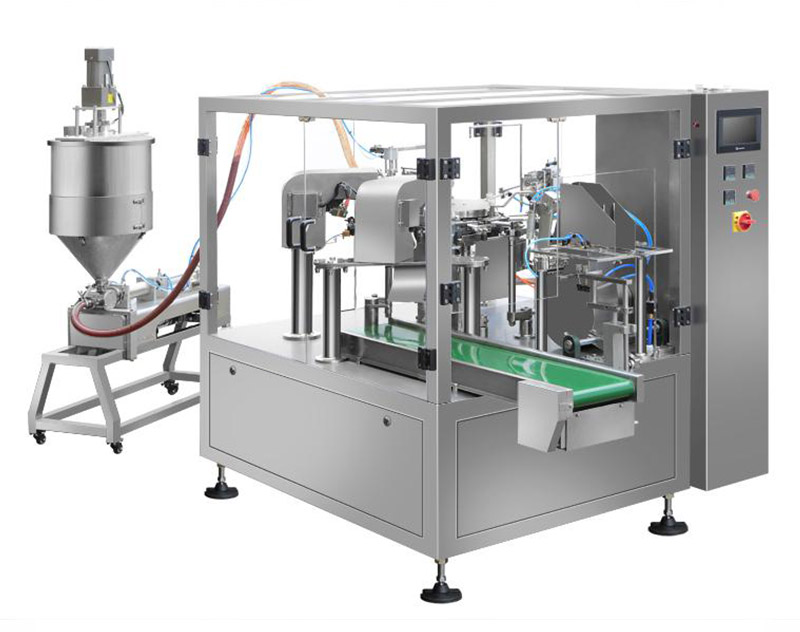

Liquid Filler Pouch Packing Machine

The Liquid Filler Pouch Packing Machine is tailored for liquid and semi-liquid products such as sauces, paste, and oils. This machine ensures accurate filling of pouches with liquid products, maintaining consistency in volume. It's designed to handle the challenges of liquid packaging, such as spillage and varying viscosities.

We understand that every business has unique requirements benefit from our extensive experience,

Integrated Solutions: We offer a seamless combination of pouch packing machines with other necessary equipment, creating a cohesive and efficient packaging line from feeding, weighing ,filling, sealing, cartoning and palletizing.

Customization: Our systems are tailored to your product specifications, packaging materials, and production capacity, ensuring you get the most effective solution. Our successful projects are covering snacks, nuts, dry fruits, trail mix, salad, meat, ready meals, hardware and etc.

Efficiency and Productivity: With a complete system, you can streamline your packaging process, reduce at least 60% manual labor, and increase output.

Quality Assurance: Our machines are designed for precision and reliability, ensuring consistent quality in every package.

Technical Support and Service: We provide comprehensive after-sales support, including installation, training, and maintenance services.

For food manufacturers, using a pouch packing machine offers a range of significant benefits that can enhance both operational efficiency and product quality. Here are some key advantages:

1.Versatility in Packaging: Pouch packing machines can handle a variety of products, from granules and powders to liquids and solids. Not only the widely application, but also widely packaging material: laminated pouches, single layer pouches, recycling material pouches, paper, foil and even retort pouches, which is particularly beneficial for manufacturers dealing with a diverse product range.

2.Cost Efficiency: By automating the packaging process, these machines reduce the need for manual labor, which can significantly cut down labor costs. Additionally, the efficient use of packaging materials helps in reducing waste, further lowering operational expenses.

3.Consistent Quality and Reliability: Automated pouch packing ensures consistent quality in packaging, with right product weight, seal integrity, and smart appearance. This consistency is crucial for maintaining brand reputation and customer trust, especially in the food industry.

4.Enhanced Product Preservation: Pouch packing machines often have the capability to remove air from the pouch or add protective gases (like nitrogen) during the packaging process. We also have vacuum pouch packing machine which is particularly beneficial for food and powder products as it extends shelf life and preserves quality by reducing exposure to air and moisture.

5.Speed and Productivity: These machines can package products at a high speed, significantly increasing production throughput. This means that food manufacturers can meet larger orders more efficiently and respond more quickly to market demands.

6.Customization and Flexibility: Pouch packing machines often allow for customization in terms of pouch size, shape, and type. This flexibility enables manufacturers to tailor their packaging to specific product needs or to create distinctive packaging designs for brand differentiation.

7.Space Efficiency: Compared to some other types of packaging machinery, pouch packing machines often have a smaller footprint, saving valuable floor space in manufacturing facilities.

8.Improved Safety and Hygiene: In the food and powder industries, maintaining hygiene is paramount. Automated packaging reduces the risk of contamination as the product has less exposure to human handling. Machines are with safety alarm and warming sign ensure operators in safe condition.

9.Ease of Distribution and Storage: Pouches are lightweight and compact, making them easier and more cost-effective to store and distribute compared to rigid packaging options.

10.Sustainability: Pouches often require less material than other types of packaging, which can reduce the environmental impact. Additionally, advancements in recyclable and biodegradable pouch materials further enhance the sustainability aspect.

In summary, pouch packing machines offer food manufacturers a highly efficient, cost-effective, and versatile solution that not only improves their operational efficiency but also enhances product quality and market responsiveness.

Selecting the best pouch packing machine for your business involves considering several key factors to ensure that the machine you choose meets your specific needs and contributes to the efficiency and quality of your packaging process. Here are the steps and considerations to keep in mind:

Assess Your Product Requirements:

Type of Product: Identify whether you're packaging solids, liquids, powders, or granules. Our machines cater to a diverse range of product types.

Product Characteristics: Consider the size, shape, consistency, and perishability of your product. Our machines are designed to handle a variety of product characteristics with precision.

Pouch Type and Material: Decide on the pouch type (stand-up, flat, gusseted, etc.) and material (foil, plastic, biodegradable materials, etc.). Our machines are versatile and compatible with multiple materials, offering you more flexibility.

Capacity and Speed: Evaluate your production needs. Our machines are built to handle high-capacity demands without compromising quality, ensuring you meet your targets efficiently.

Level of Automation:

Choose between fully automated and semi-automated machines based on your needs. Our automated solutions significantly reduce labor costs and increase efficiency.

Consider Machine Size and Versatility:

Ensure the machine fits your space and offers the versatility you need. We offer different pouch packaging solutions from small compact designs to large scale production while providing the flexibility to handle various pouch sizes and types.

Ease of Use and Maintenance:

Opt for user-friendly machines with easy maintenance. Our machines are designed with simplicity and ease of maintenance in mind, reducing downtime. It is important that choose a partner that offers robust after-sales support. We provide comprehensive after-sales service, including warranty, spare parts availability, and technical support.

Compliance with Standards:

Our machines comply with industry standards, ensuring you meet all regulatory requirements, particularly in food safety.

Research Manufacturer Reputation:

Investigate our reputation in the market. We are known for reliability and customer satisfaction, as evidenced by our numerous positive reviews and case studies.

Follow these steps to ensure your machine is cleaned properly:

Safety First: Always turn off and unplug the machine before starting the cleaning process.

Remove Loose Debris: Clear out any dust, dirt, or product residue. A compressed air can or a soft brush can be useful for this.

Disassemble and Clean: Take apart removable parts like nozzles, jaws, and knives. Consult your manual for guidance. Clean these parts with a mild detergent, rinse, and dry them thoroughly.

Interior Cleaning: Use a soft cloth or sponge for the machine's interior. Pay attention to all nooks and crannies, rinse well, and dry.

Sanitization: Sanitize all parts that come into contact with the product using a suitable food-grade sanitizer, following the manufacturer's instructions.

Lubrication: After cleaning and drying, lubricate moving parts with a food-grade lubricant as recommended by your machine's manufacturer.

Reassemble: Put your machine back together carefully, ensuring everything is aligned and secure.

Test Run: After reassembly, turn on the machine and conduct a test run to make sure everything is working correctly.

Don't Forget Regular Maintenance! In addition to cleaning, your machine requires regular maintenance. This includes checking for wear and tear, inspecting seals and gaskets, and testing safety features. Refer to your machine's manual for a recommended maintenance schedule.

By adhering to these expert cleaning and maintenance tips, you can guarantee the longevity of your rotary pouch filling and sealing machine, maintain efficient production, and ensure the quality of your products.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine