Yintoni Omele Uyijonge Xa Ukhetha Umatshini Wokupakisha Ojikelezayo Womgca Wakho Wemveliso

Intshayelelo

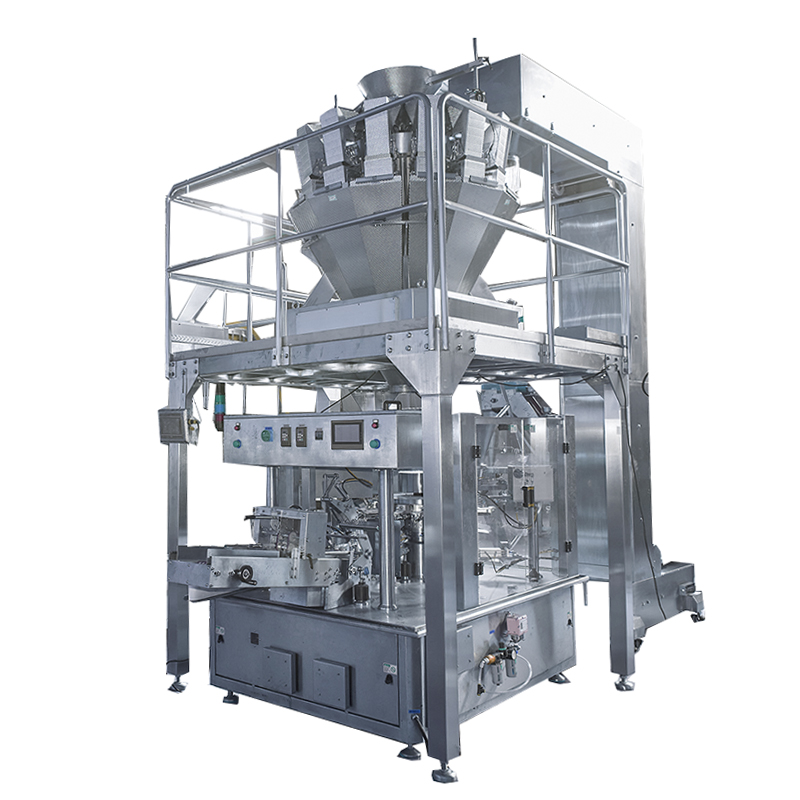

Umatshini wokupakisha ojikelezayo yinkqubo ezenzekelayo ephucula ukupakisha okukhawulezayo kwiimveliso ezinje ngeempuphu, ulwelo, kunye neegranule. Ezi matshini zisebenza nge-turret ejikelezayo enezikhululo ezininzi ezenza imisebenzi efana nokuthatha iipoko, ukuvula, ukuzalisa, ukuvala, kunye nokucoca nge-nitrogen. Zisetyenziswa kakhulu kumashishini afana nokutya, amayeza, kunye nezinto zokuthambisa ngenxa yokusebenza kakuhle kunye nokuguquguquka kwazo.

Xa ukhetha umatshini wokupakisha ojikelezayo, qwalasela izinto ezifana nokuveliswa kwemveliso, ukuhambelana kwesikhwama, kunye nokuchaneka kokutywina. Kubalulekile kwakhona ukuvavanya inkqubo yokuzalisa—nokuba yi-volumetric, i-auger, okanye i-multi-head weiger—kwaye uqinisekise ukuba iyayixhasa iintlobo zeengxowa ezifunekayo, ezifana neengxowa ezimileyo okanye eziziphu.

Iimpawu ezifana nokutshintsha izinto ngokulula, amandla e-CIP (Clean-in-Place), kunye nokudibanisa okutyibilikayo nezinye izixhobo kunokuphucula ukusebenza kakuhle kwemveliso. Makhe sithethe ngeemfuno zemveliso zeshishini lakho.

Iimfuno Zakho Zemveliso

Oomatshini bokupakisha be-rotary kufuneka bahambelane nomlinganiselo wemveliso yakho kunye neenjongo zakho. Chonga ukuba umsebenzi wakho ubandakanya ukupakisha ngesantya esiphezulu okanye ukugijima kancinci, njengoko iimodeli ezahlukeneyo zoomatshini—ezifana ne-simplex okanye i-duplex—zibonelela ngamanqanaba ahlukeneyo okusebenza kunye nokuguquguquka. Olu vavanyo luqinisekisa ukusebenza kwezixhobo ezifanelekileyo kunye nokusebenza kakuhle kweendleko.

● Iimfuno zesantya sokuvelisa kunye nomthamo

Umatshini wokupakisha iingxowa ezijikelezayo ngokuzenzekelayo ubalasele kwimisebenzi ekhawulezayo neqhubekayo, ngesantya esifikelela kwiingxowa ezingama-80 ngomzuzu kuxhomekeke kwimodeli kunye nohlobo lwemveliso. Oomatshini abanjengeemodeli ezimbini zenzelwe imveliso ephezulu, nto leyo eyenza ukuba bafaneleke kumashishini afuna imveliso ekhawulezileyo ngaphandle kokuphazamisa ukuchaneka.

● Uhlobo lweMveliso kunye neSitayile sokuPakisha

Ukuguquguquka koomatshini bokupakisha iingxowa ezijikelezayo ngokuzenzekelayo kubavumela ukuba baphathe ulwelo, iipowder, okanye izinto eziqinileyo ngokulula. Baxhasa iindlela ezahlukeneyo zokupakisha, kubandakanya iingxowa ezimileyo, ezithe tyaba, kunye neziphuphu, ukuhlangabezana neemfuno zamashishini ahlukeneyo, ukusuka ekutyeni ukuya kumayeza.

● Amandla okuphatha izinto

Umatshini wokupakisha ingxowa ojikelezayo wanamhlanje unako ukudibanisa umatshini wokuphatha izinto eziphambili, njengomatshini wokulinganisa iintloko ezininzi kunye nokugcwalisa i-auger, ukuqinisekisa ukuchaneka okuqhubekayo. Ukongeza, iimpawu ezifana nokufunyanwa kobukho bengxowa zithintela inkunkuma yezinto ngokumisa inkqubo ukuba ingxowa ayikho, nto leyo ephucula ngakumbi ukusebenza kakuhle kwemveliso.

Umgangatho kunye nokuchaneka kokupakisha

Umgangatho wokupakisha unefuthe ngqo ekugqibeleleni nasekuhambelaneni kwemveliso kuyo yonke imveliso. Ukuzaliswa nokutywinwa ngokuchanekileyo kuthintela ukuzaliswa ngaphantsi, ukuchitheka, okanye ukungcola, nto leyo ebalulekileyo ekwanelisekeni kwabathengi kunye nokuthobela imithetho. Oomatshini bokupakisha abajikelezayo bahlukile ngokukwazi kwabo ukuzalisa ngokuchanekileyo kunye nokutywina iimveliso ngesantya esiphezulu.

◆ Ukutywina nokuZalisa ngokuchanekileyo

Ukuchaneka kokutywina kuqinisekisa ukuba imveliso ihlala ikhuselekile kwizinto ezingqongileyo ezifana nomoya kunye nokufuma. Oomatshini abajikelezayo abaneeteknoloji zokuvala eziphambili, ezifana neentloko zokuvala ezilawulwa bubushushu, benza izitywino ezingangeni moya ukugcina umgangatho kunye nokunciphisa inkunkuma. Ukuchaneka kokugcwaliswa nako kubalulekile; umzekelo, ukulinganisa ngokuchanekileyo kunciphisa ukungangqinelani kubungakanani bemveliso, okubaluleke kakhulu kwizinto ezinje ngeempuphu, iioyile, okanye ulwelo ukugcina ukufana kuzo zonke iibhetshi zokupakisha.

◆ Impembelelo kubomi beShelufu yeMveliso kunye nokuHlala kwayo

Iphakheji evalwe kakuhle ibalulekile ekwandiseni ubomi beshelufu yemveliso ngokunciphisa ukuvezwa kwioksijini kunye nokufuma, okunokukhokelela ekonakalisweni. Oomatshini abajikelezayo abenzelwe ukuvala i-vacuum banokulibazisa kakhulu ukukhula kwebhaktheriya kunye ne-oxidation, bagcine ubutsha bemveliso ixesha elide. Olu buchule luluncedo ngakumbi ekutyeni, kwizinto zokuthambisa, nakwiimveliso zamayeza, apho ubutsha bubaluleke kakhulu ngexesha lokugcina nokusasaza.

Iimpawu zokuZenzekelayo

Ukwenziwa kwezinto ngokuzenzekelayo kumatshini wokuzalisa ingxowa ejikelezayo kuphucula ukusebenza kakuhle, ukuchaneka, kunye nokukhupha, okwenza kube yinto ebalulekileyo kwimigca yemveliso efuna imveliso ephezulu. Iinkqubo zanamhlanje zibandakanya ubuchwepheshe obuphambili obufana nokuhamba okujikelezayo okuqhubekayo, okususa ixesha lokungasebenzi kwaye kuphucula ukuhambelana kokusebenza.

✔ Ujongano olusebenziseka lula kunye noLawulo

Inkalo ephambili yoomatshini bokupakisha abazenzekelayo yindlela abajonga ngayo izinto. Aba matshini bayilwe ngeephaneli zolawulo ezisebenziseka lula, ezihlala zibandakanya ii-touchscreens kunye nezicwangciso ezinokwenziwa ngokwezifiso. Oku kwenza kube lula kubasebenzisi ukulungisa iiparameter ngokukhawuleza, kunciphisa i-learning curve kunye neempazamo ezinokwenzeka zokusebenza.

✔ Inqanaba lokuZenzekelayo

Oomatshini bokupakisha be-rotary bahluka ngokwamanqanaba oomatshini abasebenza ngokuzenzekelayo, ukusuka kwiinkqubo ezizenzekelayo ukuya kwimigca esebenza ngokuzenzekelayo ngokupheleleyo. Iimodeli ezizenzekelayo ngokupheleleyo ziphucula imveliso ngokudibanisa ngaphandle kokuphazamiseka nee-conveyors kunye nezinye izixhobo, zinciphisa ukungenelela kwabantu kulo lonke inkqubo. Oomatshini abanjalo baluncedo ngakumbi kumashishini asebenzisa umthamo omkhulu.

Iimfuno zeMigca yoMzimba kunye neNdawo yoMzimba

Ubungakanani bomatshini wokupakisha ingxowa ejikelezayo buchaphazela indlela ohambelana ngayo nendawo yakho yokuvelisa. Abavelisi kufuneka bavavanye uyilo olunemodyuli okanye olunokulungiselelwa ukuqinisekisa ukuguquguquka kunye nokukhula kwixesha elizayo.

● Ubukhulu Bomzimba Bomatshini

Ubungakanani bomatshini wokuzalisa ingxowa ejikelezayo buchaphazela ngokuthe ngqo ucwangciso lomgangatho wemveliso. Iimodeli ezincinci zivumela ukuhlanganiswa okulula kwimigca ekhoyo ngaphandle kokuphazamisa imisebenzi yokusebenza, ngelixa oomatshini abakhulu banokufuna uyilo olwenziwe ngokwezifiso.

● Iimodeli okanye iiDesigns ezinokwenziwa ngokwezifiso

Uyilo lweemodyuli lubonelela ngokuguquguquka ngokuvumela abavelisi ukuba balungelelanise umatshini kwiimveliso ezahlukeneyo okanye iimfuno zokupakisha ngaphandle kokuphazamiseka okukhulu. Oku kuguquguquka kwenza kube lula ukwazisa iimveliso ezintsha ngaphandle kokutshintsha yonke inkqubo, kuqinisekisa ukwandiswa nokusebenza kakuhle kunye neemfuno zemveliso ezitshintshayo.

Ulawulo lwesantya kunye nexesha lokuphumla

Ukulawula isantya kunye nexesha lokungasebenzi kubalulekile ekugcineni ukusebenza kakuhle. Oomatshini abane-CPM ephezulu (ii-cycles ngomzuzu) kunye notshintsho olukhawulezayo banceda ekunciphiseni ukuphazamiseka kwaye bagcine imveliso ihamba kakuhle.

◆ Isantya somatshini

Isantya sokubaleka, esidla ngokulinganiswa kwingxowa ngomzuzu (PPM), sisalathisi esibalulekileyo sokusebenza. Amazinga aphezulu e-PPM abalulekile kwimisebenzi ephezulu, kodwa ukugcina ukuchaneka kwisantya esinjalo kunokuba nzima. Ezinye iimatshini zifikelela kwisantya esifikelela kwi-45 PPM, zilungelelanisa isantya kunye nomgangatho ukuze zifezekise iinjongo zemveliso ngokufanelekileyo.

◆ Amaxesha okutshintsha kunye nokuguquguquka

Ukutshintsha ngokukhawuleza nangokusebenzayo kubalulekile ekunciphiseni ixesha lokungasebenzi, ingakumbi xa kutshintshwa iintlobo zeemveliso okanye iifomathi zokupakisha. Oomatshini abatsha baxhasa utshintsho olucwangcisiweyo ngokusebenzisa iinkqubo ezenzekelayo kunye ne-interfaces ezinobuchule zoomatshini babantu (ii-HMI), nto leyo enciphisa kakhulu uhlengahlengiso olwenziwe ngesandla.

Ukuthobela iMigangatho yoShishino

Oomatshini bokupakisha be-rotary kufuneka balandele imigaqo engqongqo yoshishino ukuqinisekisa ukhuseleko, ukusebenza kakuhle, kunye nokuzinza. Ukuthobela imigangatho yokutya, yombane, kunye neyokusingqongileyo kubalulekile ukuze kuhlangatyezwane neemfuno zomthetho nezokusebenza.

▼ Imigangatho kunye neziqinisekiso zoKhuseleko lokutya (HACCP, FDA, GMP)

Iimashini zokupakisha ezisetyenziselwa iimveliso zokutya kufuneka zihambelane nemigangatho efana ne-HACCP, izikhokelo ze-FDA, kunye neMikhwa emihle yoKuvelisa (GMP). Ezi nkqubo ziqinisekisa ukuba iindawo zemveliso zinciphisa iingozi zongcoliseko kwaye zigcina umgangatho wemveliso kuyo yonke inkqubo, nto leyo ebalulekileyo ekuvunyweni komthetho kunye nokuthenjwa kwabathengi.

▼ Ukuthobela uKhuseleko loMbane nooMatshini (Uphawu lwe-CE, iMigangatho ye-ISO)

Oomatshini be-rotary kufuneka bahlangabezane neemfuno zokumakisha ze-ISO kunye ne-CE ukuqinisekisa ukhuseleko lokusebenza kunye nokuthembeka. Ezi ziqinisekiso zigubungela ukhuseleko lombane, loomatshini, kunye nolwemisebenzi, zinciphisa iingozi ngexesha lokusetyenziswa nokugcinwa komatshini.

▼ Imigangatho Yokusebenza Kokusingqongileyo Nokusebenza Kakuhle Kwamandla

Oomatshini banamhlanje abajikelezayo kufuneka bahlangabezane nemigangatho yokusingqongileyo yokusetyenziswa kakuhle kwamandla kunye nokunciphisa inkunkuma. Iziqinisekiso ezifana ne-FSSC 22000 zigxininisa uzinzo kwiinkqubo zokupakisha, zikhuthaza ukusetyenziswa ngononophelo kwezinto kunye namandla ngelixa kugcinwa ukhuseleko lokutya.

Isiphelo

Xa ukhetha umatshini wokupakisha ojikelezayo kumgca wakho wemveliso, kubalulekile ukuvavanya izinto ezifana nesantya, ukuchaneka, kunye nokuthobela imigangatho yoshishino. Oomatshini abafana nomatshini wokupakisha ojikelezayo we-SW-8-200 onesitishi se-8 baqinisekisa ukuzaliswa nokutywinwa rhoqo ngelixa behlangabezana neemfuno zomthetho zamacandelo afana nokutya kunye namayeza. Aba matshini balula ukusebenza, baphucula ukusebenza kakuhle kunye nomgangatho wemveliso.

Ukuze ufumane iziphumo ezilungileyo, khetha umenzi othembekileyo ofana noSmart Weigh onika izisombululo eziphambili ezifana nomatshini wokupakisha ojikelezayo we-SW-8-200 . Ngokugxila kwabo kuyilo olunokwenziwa ngokwezifiso kunye nemisebenzi egcina amandla, oomatshini beSmart Weigh Pack balungiselelwe ukuhlangabezana neemfuno ezahlukeneyo zokupakisha ngelixa begcina imigangatho ephezulu yokusebenza kunye nokuzinza.

I-Smart Weight yinkokheli yehlabathi kwiinkqubo zokupakisha ezichanekileyo nezihlanganisiweyo, ezithembeke ngabathengi abangaphezu kwe-1,000 kunye nemigca yokupakisha engaphezu kwe-2,000 kwihlabathi liphela. Ngenkxaso yasekuhlaleni e- Indonesia, eYurophu, e-USA nase-UAE , sinikezela ngezisombululo zemigca yokupakisha ejikajikayo ukusuka ekutyiseni ukuya ekufakeni iipalethi.

Ikhonkco elikhawulezayo

Umatshini wokupakisha