Kusukela ngo-2012 - i-Smart Weight izibophezele ekusizeni amakhasimende ukwandisa umkhiqizo ngezindleko eziphansi.

Umhlahlandlela Ophelele we-Trey Denester

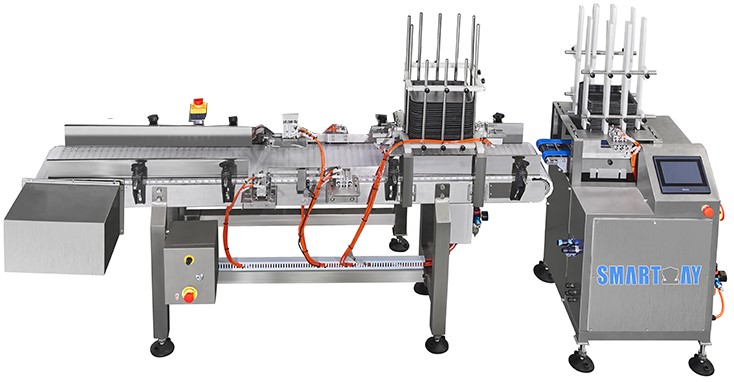

Ezweni lokuncintisana lokupakisha ukudla, isidingo sezixazululo ezisebenza ngokuzenzakalelayo ezithembekile nezisebenzayo sibaluleke kakhulu. Ukuhlangabezana nezidingo zamakhasimende ngokuqinisekisa inhlanzeko nokuthembeka kubalulekile kulo mkhakha. Phakathi kobuchwepheshe obuhlukahlukene obuqinisekisa ukusebenza okubushelelezi nokungaphazanyiswa, ama-denester e-tray avelele njengengxenye ebalulekile. Le mishini ye-denester ye-tray yenzelwe ukuhlukanisa ngokuzenzakalelayo nokubeka ama-tray ezinhlelweni zokuhambisa, ilungele ukugcwalisa nokuvala. Lo mhlahlandlela uhlola izici ezibalulekile ze

imishini ye-denester, ukubaluleka kwayo emigqeni yokupakisha yesimanje, nokuthi yini okufanele uyicabangele lapho ukhetha umshini ofanele izidingo zakho.

Ziyini Izithambisi Zethreyi?

Ama-denesters ethreyi, aziwa nangokuthi ama-de nesters, ayizingxenye ezibalulekile emigqeni yokupakisha ezenzakalelayo, ikakhulukazi embonini yokudla. Aphatha amathreyi ezinto ezahlukahlukene nobukhulu, aqinisekisa ukuthi ahlukaniswe kahle futhi abekwe emgqeni wokukhiqiza. Lokhu kuzenzakalelayo kunciphisa kakhulu ukuphathwa ngesandla, kusheshisa inqubo, futhi kuthuthukisa ukusebenza kahle okuphelele.

Izici Eziyinhloko Zama-Denesters E-Tray Yanamuhla Yama-Multiple Tray Stacks

Ukunemba kanye nesivinini: Imishini yakamuva ye-tray denester yenzelwe ukuphatha umthamo omkhulu wama-tray ngokunemba okuphawulekayo futhi iwabeke ngokunembile ngesivinini esiphezulu. Lokhu kubalulekile ekugcineni ukugeleza kokukhiqiza okuqhubekayo, ukunciphisa isikhathi sokungasebenzi, nokuqinisekisa ukuthi ama-tray abekwe kahle njalo ezinqubweni zokupakisha ezilandelayo.

Ukuguquguquka: Ama-denester ethreyi anamuhla aklanyelwe ukwamukela izinhlobo ezahlukene zamathreyi nosayizi. Kungakhathaliseki ukuthi ukusebenza kwakho kuhilela amathreyi epulasitiki, e-foil, noma abolayo, le mishini ingalungiswa ukuze ihlangabezane nezidingo zakho ezithile, okuvumela ukuguquguquka ekukhiqizeni. Ngaphezu kwalokho, iyakwazi ukuphatha ama-tray stack amaningi, iqinisekise ukutholakala okuqhubekayo kanye nokwenza ngcono ukusebenza komsebenzi.

Umklamo Wenhlanzeko: Ezimbonini lapho inhlanzeko ibaluleke kakhulu, njengokupakisha ukudla, imishini ye-denester ivame ukwenziwa ngezinto ezifana nensimbi engagqwali. Le mishini yenzelwe ukuhlanza kalula, ukunciphisa ingozi yokungcola nokuqinisekisa ukuhambisana nezindinganiso zezempilo nokuphepha.

Ukugcinwa Okuphansi: Ukuqina nokuthembeka kuyizimpawu ezibalulekile zanoma yimiphi imishini yokupakisha. Iyunithi ngayinye yemishini ye-denester yakhelwe ukudinga ukulungiswa okuncane, okuqinisekisa ukusebenza kwesikhathi eside, okungabizi kakhulu. Lokhu kunciphisa isikhathi sokungasebenzi futhi kugcina umugqa wakho wokukhiqiza usebenza kahle.

Izicelo Zemboni

Imishini yokukhipha ama-tray denester ibaluleke kakhulu emikhakheni ehlukahlukene embonini yokupakisha ukudla:

Inyama Nezinkukhu: Isetshenziswa ekupakisheni imikhiqizo emisha, eqandisiwe, nevalwe nge-vacuum, imishini ye-denester iqinisekisa ukuphathwa kwamathileyi ngendlela enembile nehlanzekile, kunciphisa ingozi yokungcola.

Ibhikawozi kanye ne-Confectionery: Le mishini ilungele ukuphatha amathileyi athambile asetshenziswa ekupakisheni izinto ezibhakiwe namaswidi, iqinisekisa ukuthi ithileyi ngalinye libekwe kahle ukuze ligcwaliswe futhi livalwe.

Ukudla Okulungele: Emkhakheni wokudla okulungele okhula ngokushesha, ama-denester ethreyi anikeza isivinini kanye nokunemba okudingekayo ukuze kuhlangatshezwane nezidingo eziphezulu zokukhiqiza, okuqinisekisa ukuthi ukudla kupakishwa kahle nangokuphephile. Ukulayisha umkhiqizo kahle emgqeni wokukhiqiza kubalulekile ekugcineni ukuphepha, ubulula, kanye nokukhula emisebenzini yokukhiqiza.

Ukukhetha Umshini Wokwenza I-Trey Denester Ofanele

Uma ukhetha i-denester yethreyi yokusebenza kwakho, izici eziningana kufanele zicatshangelwe:

Isivinini Sokukhiqiza : Qinisekisa ukuthi indawo ehlanzayo ingahlangabezana nezidingo zomkhiqizo wakho ngaphandle kokulahlekelwa ukunemba.

Ukuhambisana Kwethreyi : I-denester kufanele ikwazi ukuphatha izinhlobo ezithile zamathreyi owasebenzisayo, kungakhathaliseki ukuthi ayipulasitiki, i-foil, noma enye into.

Ubulula Bokuhlanganisa : Umshini wokufaka ithreyi kufanele uhlanganiswe kalula nomugqa wakho wokupakisha okhona, unciphise isidingo sokuguqulwa okukhulu.

Ukuhlanzeka Nokunakekelwa : Funa imishini eyenzelwe ukuhlanza okulula nokunakekelwa okuncane ukuze kuncishiswe isikhathi sokungasebenzi futhi kuqinisekiswe indawo yokukhiqiza engenamagciwane.

Isiphetho

Ukutshala imali emshinini we-denester osezingeni eliphezulu kubalulekile kunoma yikuphi ukusebenza kokupakisha ukudla okuhlose ukuthuthukisa ukusebenza kahle, ukunciphisa umsebenzi wezandla, nokugcina amazinga aphezulu okuhlanzeka. Kunezixazululo eziningi zokufaka i-tray denesting ezitholakalayo ukuze zihlangabezane nezidingo ezahlukene embonini. Njengoba ubuchwepheshe obusemuva kwe-trey denesters buqhubeka nokukhula, le mishini iya ngokuya inembile, iguquguquka, futhi ithembeke, okwenza ibe yimpahla ebalulekile emigqeni yokupakisha yesimanje.

Ngokukhetha imishini efanele yokukhiqiza, ungenza ngcono inqubo yakho yokukhiqiza, uqinisekise ukuthi umugqa wakho wokupakisha usebenza kahle, ngempumelelo, futhi uhambisana nezindinganiso zomkhakha.

Ukulungele ukuthatha imisebenzi yakho yokupakisha uye ezingeni elilandelayo? Xhumana ne-Smart Weight namuhla ukuze ufunde kabanzi ngezixazululo zethu ezithuthukisiwe zokufaka amathreyi. Ochwepheshe bethu balapha ukuzokusiza ukuthola imishini ephelele yokuhlangabezana nezidingo zakho zokukhiqiza. Ungalindi—xhumana nathi manje bese uthola ukuthi i-Smart Weight ingawuguqula kanjani umugqa wakho wokupakisha ngobuchwepheshe obusezingeni eliphezulu bokuzenzakalela.

I-Smart Weight ingumholi womhlaba wonke ezinhlelweni zokupakisha ezinesisindo esinembile kakhulu nezihlanganisiwe, ethenjwa amakhasimende angaphezu kwe-1,000 kanye nemigqa yokupakisha engaphezu kwe-2,000 emhlabeni jikelele. Ngokusekelwa kwendawo e- Indonesia, eYurophu, e-USA nase-UAE , sinikeza izixazululo zomugqa wokupakisha we-turnkey kusukela ekuphakeleni kuya ekufakeni ama-pallet.

Isixhumanisi Esisheshayo

Umshini Wokupakisha