Tray Denester Comprehensive Guide

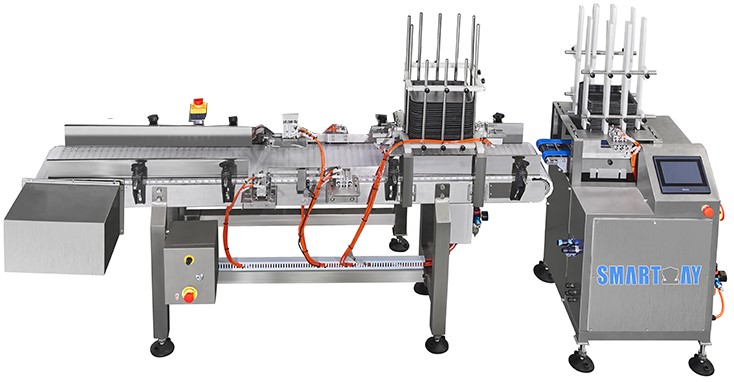

In the competitive world of food packaging, the need for reliable and efficient automation solutions is paramount. Meeting the needs of customers by ensuring hygiene and reliability is crucial in this industry. Among the various technologies that ensure smooth and uninterrupted operations, tray denesters stand out as a critical component. These tray denester machines are designed to automatically separate and place trays onto conveyor systems, ready for filling and sealing. This guide delves into the key aspects of

denester machines, their significance in modern packaging lines, and what to consider when selecting the right machine for your needs.

What Are Tray Denesters?

Tray denesters, also known as de nesters, are essential components in automated packaging lines, particularly in the food industry. They handle trays of various materials and sizes, ensuring they are properly separated and positioned on the production line. This automation significantly reduces manual handling, speeds up the process, and enhances overall efficiency.

Key Features of Modern Tray Denesters for Multiple Tray Stacks

Precision and Speed: The latest tray denester equipments are engineered to handle a high volume of trays with remarkable precision and accurately place them at high speed. This is critical for maintaining a continuous production flow, reducing downtime, and ensuring that the trays are consistently positioned for subsequent packaging processes.

Versatility: Modern tray denesters are designed to accommodate a wide range of tray types and sizes. Whether your operation involves plastic, foil, or biodegradable trays, these machines can be adjusted to meet your specific requirements, allowing for flexibility in production. Additionally, they are capable of handling multiple tray stacks, ensuring a continuous supply and optimizing operational workflows.

Hygienic Design: In industries where hygiene is paramount, such as food packaging, denester machines are typically made from materials like stainless steel. These machines are designed for easy cleaning, reducing the risk of contamination and ensuring compliance with health and safety standards.

Low Maintenance: Durability and reliability are key features of any packaging equipment. Each unit of denester equipment is built to require minimal maintenance, ensuring long-term, cost-effective operation. This minimizes downtime and keeps your production line running smoothly.

Industry Applications

Tray denester machines are indispensable in various sectors of the food packaging industry:

Meat and Poultry: Used in the packaging of fresh, frozen, and vacuum-sealed products, denester machines ensure precise and hygienic handling of trays, reducing the risk of contamination.

Bakery and Confectionery: These machines are ideal for handling the delicate trays used in packaging baked goods and sweets, ensuring that each tray is accurately placed for filling and sealing.

Ready Meals: In the rapidly growing ready-meal sector, tray denesters provide the speed and precision necessary to meet high production demands, ensuring that meals are packaged efficiently and securely. Efficient product loading on the production line is crucial for maintaining safety, simplicity, and scalability in manufacturing operations.

Selecting the Right Tray Denester Machine

When choosing a tray denester for your operation, several factors should be considered:

Production Speed: Ensure that the place denester can meet the throughput requirements of your production line without sacrificing accuracy.

Tray Compatibility: The denester should be capable of handling the specific types of trays you use, whether they are plastic, foil, or another material.

Ease of Integration: The tray denester machine should easily integrate with your existing packaging line, minimizing the need for extensive modifications.

Hygiene and Maintenance: Look for machines designed for easy cleaning and minimal maintenance to reduce downtime and ensure a sterile production environment.

Conclusion

Investing in a high-quality denester machine is essential for any food packaging operation that seeks to enhance efficiency, reduce manual labor, and maintain high standards of hygiene. A wide array of tray denesting solutions is available to cater to various needs in the industry. As the technology behind tray denesters continues to evolve, these machines are becoming even more precise, versatile, and reliable, making them an invaluable asset in modern packaging lines.

By selecting the right denester equipment, you can optimize your production process, ensuring that your packaging line operates smoothly, efficiently, and in compliance with industry standards.

Ready to take your packaging operations to the next level? Contact Smart Weigh today to learn more about our advanced tray denesting solutions. Our experts are here to help you find the perfect equipment to meet your production needs. Don’t wait—reach out now and discover how Smart Weigh can transform your packaging line with cutting-edge automation technology.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine