Smart Weigh's Unmanned Automatic Chips Packaging Machine System is designed to modernize and optimize your packaging operations. This system integrates a multihead weigher with a vertical packing system, ensuring precision, efficiency, and reliability while creating eye-catching pillow bags for chips. With 12 years of expertise, Smart Weigh delivers innovative, customized packaging solutions tailored to diverse production needs. From semi-automatic to fully automated systems, our machines combine advanced technology with scalable options to fit any budget. Supported by a global network, we provide seamless installation, training, and ongoing assistance to ensure peak performance and minimal downtime.

![400 Packs/min Corn Chips Packaging System Line 2]()

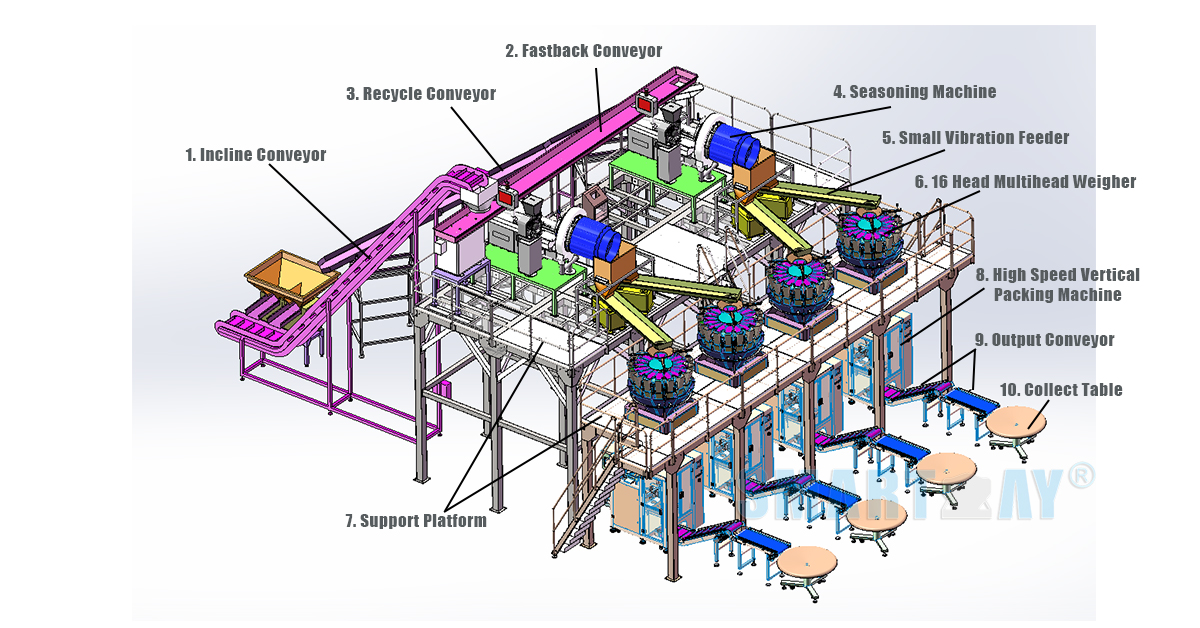

What are the components of High Speed Corn Chips Packaging Machine?

bg

![400 Packs/min Corn Chips Packaging System Line 3]()

Below is a list of components for the Unmanned Automatic Chips Packaging Machine System:

Feed Conveyor: Incline conveyor for efficient feeding.

Online Seasoning System: Quickly and consistently adds seasoning before weighing and packing.

Fast Return Conveyor: Reduces product damage and improves hygiene, feeds chips to multihead weigher

Recycling Conveyor: Forms a closed loop to reduce waste.

Multihead Weigher: 16-head weigher for precise weighing.

Vertical Packing Machine: Automatically forms pillow bags from roll film and seals them with chips.

Output Conveyor: Delivers finished bags to the next equipment.

Optional Add-ons

1. Date Coding Printer

Thermal Transfer Overprinter (TTO): Prints high-resolution text, logos, and barcodes.

Inkjet Printer: Suitable for variable data printing directly on packaging films.

2. Nitrogen Flushing System

Modified Atmosphere Packaging (MAP): Replaces oxygen with nitrogen to inhibit oxidation and microbial growth.

Freshness Preservation: Ideal for extending the shelf life of perishable snack products.

3. Metal Detector

Integrated Detection: Inline metal detection to identify ferrous and non-ferrous metal contaminants.

Automatic Rejection Mechanism: Ensures contaminated packages are removed without halting production.

4. Check Weigher

Post-Packaging Verification: Weighs finished packages to ensure compliance with weight specifications.

Data Logging: Records weight data for quality control and regulatory compliance.

5. Secondary Wrapping Machine

Technical Specifications

bg

| Specification | Details |

|---|

| Weighing Range | 30 grams to 90 grams |

| Number of Weighing Heads | 16 heads |

| Packing Speed | 100 bags/min per line, total system 400 bags/min |

| Bag Style | Pillow bag |

| Bag Size Range | Width: 80 mm - 250 mm

Length: 100 mm - 350 mm |

| Film Thickness | 0.04 mm - 0.09 mm (Assumed similar to cinnamon bun) |

| Power Supply | 220V, 50/60Hz, single phase |

| Air Consumption | 0.6 m³/min at 0.6 MPa (Assumed similar to cinnamon bun) |

| Control System | Multihead weigher: Modular board control system with 7-inch touch screen

Packing machine: PLC with 7-inch color touch-screen interface |

| Language Support | Multilingual (English, Spanish, Chinese, Korean, etc.) |

bg

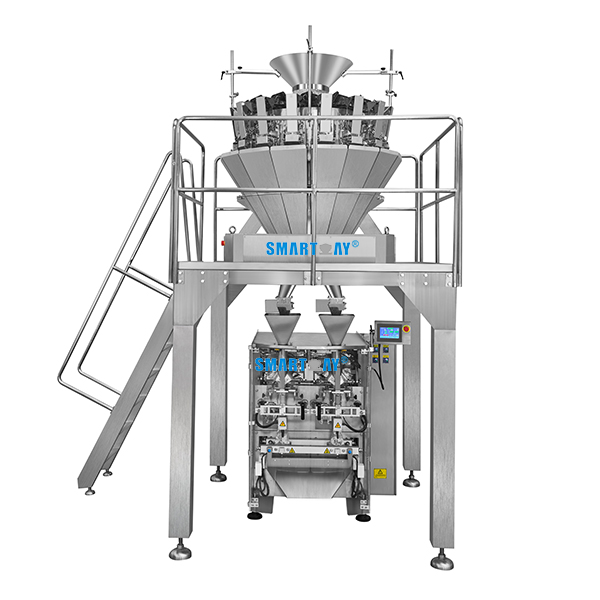

Multihead Weigher for Precision Weighing

Our multihead weigher is engineered for exceptional accuracy and speed:

High-Precision Load Cells: Each head is equipped with sensitive load cells to ensure precise weight measurements, reducing product giveaway.

Flexible Weighing Options: Adjustable parameters to accommodate various snack sizes and shapes.

Optimized Speed: Efficiently handles high-speed operations without compromising on accuracy, enhancing productivity.

Vertical Packing Machine for precision cutting

The vertical packing machine forms the core of the packaging system:

Pillow Bag Formation: Crafts visually appealing pillow bags that enhance product presentation and brand image.

Advanced Sealing Technology: Utilizes heat-sealing mechanisms to ensure airtight packaging, preserving freshness and extending shelf life.

Versatile Bag Sizes: Easily adjustable to produce different bag widths and lengths, catering to diverse market demands.

High-Speed Operation

Integrated System Design: Synchronization between the multihead weigher and packing machine enables smooth and rapid packaging cycles.

Enhanced Throughput: Capable of packaging up to 60 bags per minute, depending on product characteristics and packaging specifications.

Continuous Operation: Designed for 24/7 operation with minimal maintenance interruptions.

Gentle Product Handling

Minimal Drop Height: Reduces the distance Kanelbulle fall during packaging, minimizing breakage and maintaining product integrity.

Controlled Feeding Mechanism: Ensures a steady flow of Kanelbulle into the weighing system without clogging or spillage.

User-Friendly Interface

Touch-Screen Control Panel: Intuitive interface with easy navigation, allowing operators to monitor and adjust settings effortlessly.

Programmable Settings: Save multiple product parameters for quick changeovers between different packaging requirements.

Real-Time Monitoring: Displays operational data such as production speed, total output, and system diagnostics.

Durable Stainless Steel Construction

SUS304 Stainless Steel: Crafted with high-quality, food-grade stainless steel for durability and compliance with hygiene standards.

Robust Build Quality: Designed to withstand rigorous industrial environments, reducing long-term maintenance costs.

Easy Maintenance and Cleaning

Hygienic Design: Smooth surfaces and rounded edges prevent residue buildup, facilitating quick and thorough cleaning.

Tool-Free Disassembly: Key components can be disassembled without tools, streamlining maintenance procedures.

Compliance with Food Safety Standards

Certifications: Meets international standards such as CE, ensuring compliance and facilitating global market access.

Quality Control: Rigorous testing protocols ensure each machine meets our strict quality benchmarks before delivery.

The Smart Weigh Chips Packing Machine is ideal for packaging:

![400 Packs/min Corn Chips Packaging System Line 6]()

Baked Snacks

chips

Breadsticks

Crackers

Mini pastries

![400 Packs/min Corn Chips Packaging System Line 7]()

Confectioneries

Candies

Chocolate bites

Gummies

![400 Packs/min Corn Chips Packaging System Line 8]()

Nuts and Dried Fruits

Almonds

Peanuts

Cashews

Raisins

![400 Packs/min Corn Chips Packaging System Line 9]()

Other Granular Products

Cereals

Seeds

Coffee beans

Offer Different Automation Grades Corn Chips Packing Solutions

bg

1. Semi-Automatic Solutions

Ideal for Small Businesses: Enhances efficiency while allowing for manual oversight.

Features:

Manual product feeding

Automated weighing and packaging

Basic control interface

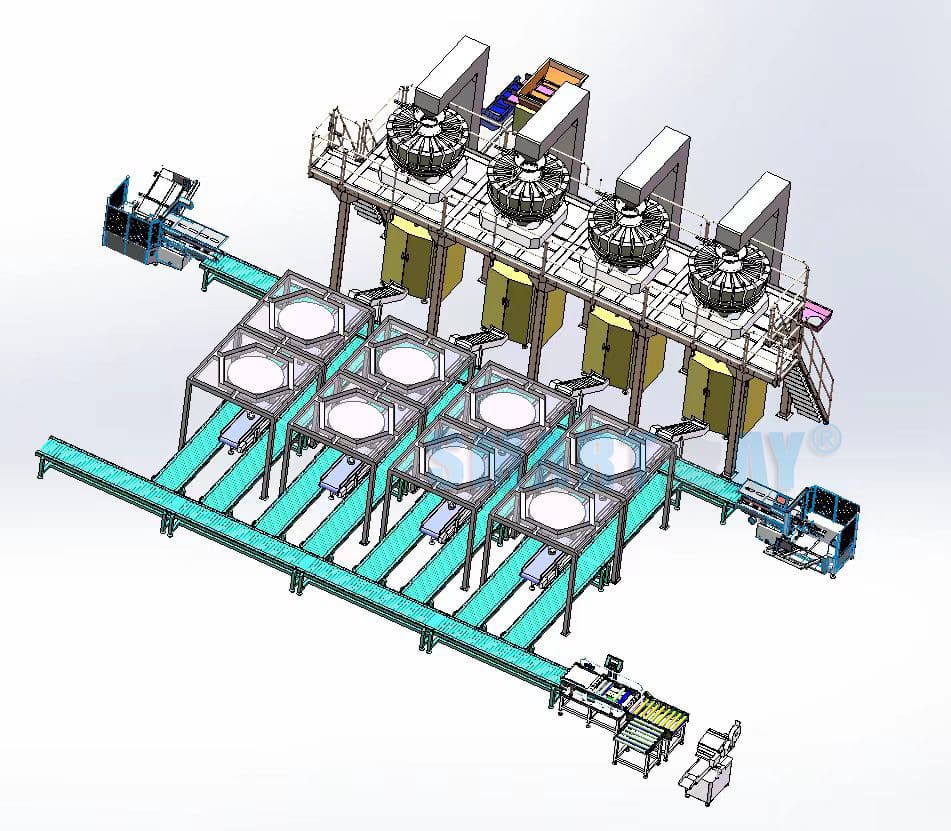

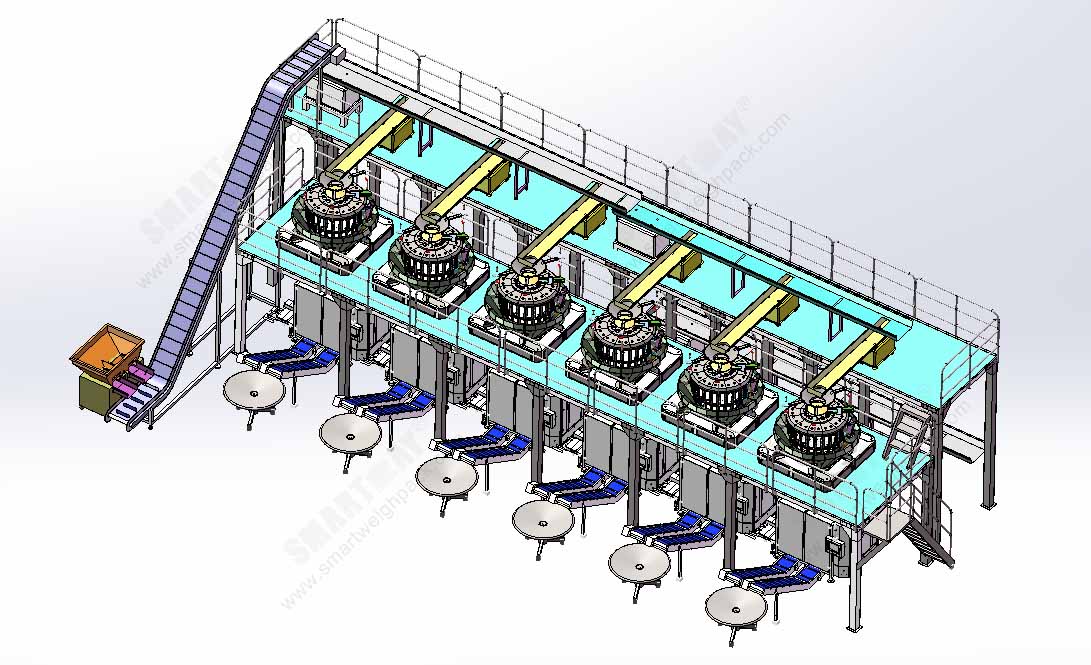

2. Fully Automatic Systems

Designed for High-Volume Production: Minimizes human intervention for consistent, high-speed operation.

Features:

Automatic product feeding via conveyors or elevators

Integrated optional add-ons

Customized Configurations for Secondary Wrapping Machine and Palletizing System

![400 Packs/min Corn Chips Packaging System Line 10]()

100 packs/min Solution

high speed 24 head with twin

former vffs

![400 Packs/min Corn Chips Packaging System Line 11]()

Fully Automatic Solution

Including auto cartoning

1. Comprehensive Support

Consultation Services: Expert advice on selecting the right equipment and configurations.

Installation and Commissioning: Professional setup to ensure optimal performance from day one.

Operator Training: In-depth training programs for your team on machine operation and maintenance.

2. Quality Assurance

Stringent Testing Procedures: Each machine undergoes thorough testing to meet our high-quality standards.

Warranty Coverage: We offer warranties that cover parts and labor, providing peace of mind.

3. Competitive Pricing

Transparent Pricing Models: No hidden costs, with detailed quotations provided upfront.

Financing Options: Flexible payment terms and financing plans to accommodate budgetary constraints.

4. Innovation and Development

Research-Driven Solutions: Continuous investment in R&D to introduce cutting-edge features and enhancements.

Customer-Centric Approach: We listen to your feedback to improve our products and services continually.

Ready to take your snack packaging to the next level? Contact Smart Weigh today for a personalized consultation. Our team of experts is eager to help you find the perfect packaging solution tailored to your business needs.