Choosing the Right Target Batcher System for Your Products

If you have a huge amount of raw product and a butcher to divide it into small batches with the exact specified weight? That’s where you need a target batcher system for your products.

Now, choosing the right target batching system is kind of difficult as there are multiple options available, and most companies don’t know what extra factors they should look for.

We will break it down in this guide and help you choose the right target.

What is a Target Batcher and How Does It Work?

A target batcher is a specialized machine designed to divide a bulk product into precise batches that meet a target weight.

You can pour a huge amount of raw materials, and the target batching system will automatically pack the items for you to the precise weight. It’s mostly useful for dry fruits, candies, frozen food, nuts, etc.

Here's how it works in simple terms:

Products are fed into multiple weighing heads. Each head weighs a portion of the product, and the system intelligently combines the weights from selected heads. Once selected, it proceeds further to create the most accurate batch possible.

Once the target weight is achieved, the batch is released into a bag or container for packaging. After the end of the process, the production line continues if there is any further process needed.

Key Factors in Selecting a Target Batcher System

Choosing the right batching system isn’t just about picking a machine that looks good on paper. Instead, you have to consider several technical and operational aspects.

We will now see a few important areas you should focus on.

▶Accuracy and Precision

When it comes to target batches, you need to ensure the machine has top-level accuracy and precision. Some machines misbehave because it has to deal with multiple batches at the same time. Make sure the target batcher can handle large quantities with proper accuracy.

▶Flexibility and Adaptability

You need to ask certain questions here. Can the batcher handle more than one product type? Can it adjust for different weights, sizes, and product characteristics? This will give you a proper idea about the flexibility of the machine.

▶Integration with Existing Systems

Make sure the target batcher can integrate with your conveyor system. Most people add a target butcher before the check weigher or sealing machine. The integration should be smooth and shouldn’t cause any issues.

▶Ease of Use and Maintenance

If the machine has a complex learning curve, it will be difficult for your staff to learn the machine. So, look for user-friendly interfaces with easy maintenance. You can also see if the parts replacements are possible.

How to Pick the Right Target Batcher

Let's see the exact factors you should look for while picking the right target batching system for your enterprise.

◆Know Your Product Type

First and foremost, start by knowing your product type. Whether it’s dry, sticky, frozen, fragile, or granular? Each type has a different batcher. For example, frozen foods might need stainless steel hoppers with anti-stick surfaces.

◆Define Your Batch Size and Accuracy Needs

Some products require small, high-precision batches while others are fine with a broader margin. Know the range and select the right weighing heads and load cell capacity according to your batch requirements.

◆Understand Your Speed and Output Requirements

Speed matters when you're trying to meet high-volume demands. A batcher with more heads can typically produce batches faster. So, understand your daily needs and how many of them can be targeted and batched to complete.

◆Make Sure It Fits Your Existing Production Line

Take note of the physical layout and configuration of your current production line. Will the new machine fit in without causing disruptions? Especially keep in mind the machines before and after the batcher.

◆Ease of Operation and Maintenance is a Must

A touch-screen interface with some pre-set programs will make the target batcher operation extremely easy. In the same way, you can see if the machine is easily cleanable with minimal downtime.

Smart Weigh Target Batcher Options

Let's see some of the best solutions from Smart Weigh. These target batcher options are perfect for all companies, whether small businesses or large enterprises.

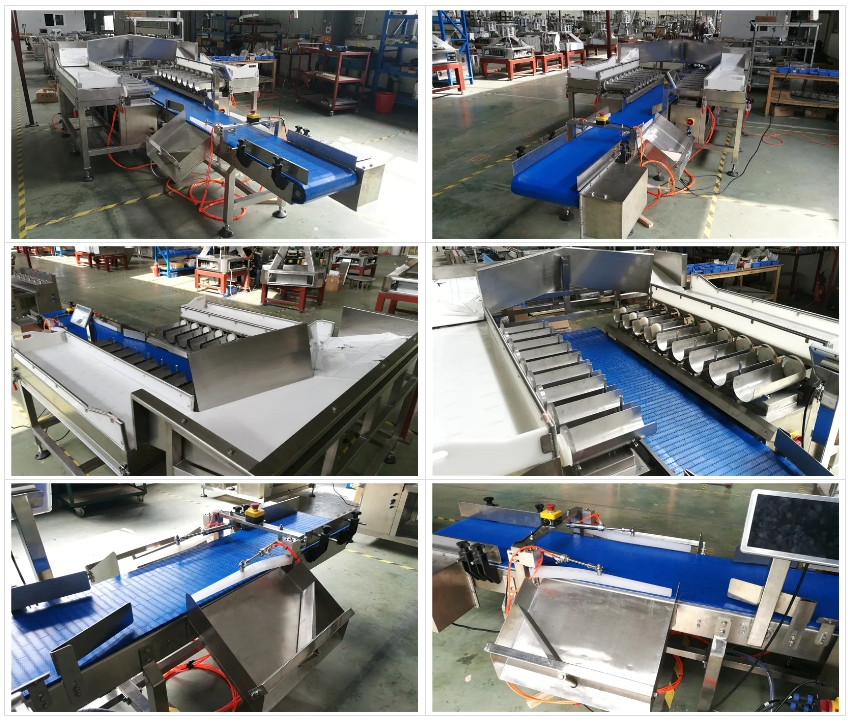

✔Smart Weigh 12-Head Target Batching System

This system is ideal for mid-range production environments. With 12 weighing heads, it comes with the right balance between speed and accuracy. If you have snacks or frozen items, this is a perfect target batching system you can get. It comes with high-accuracy and speed, save raw materials and manual cost. You can also use it for mackerel, haddock fillets, tuna steaks, hake slices, squid, cuttlefish, and other products.

As a mid-sized company, some may be using manual bagging stations while some use automatic ones. You don’t need to worry as the Smart Weigh 12-head target batcher can integrate with both of these easily. The weighing method is a load cell, and it comes with 10 10-inch touch screen for easy control.

✔Smart Weigh 18 Head Hopper Type Target Batcher for Fish

Smart Weigh's SW-LC18 model uses 18 individual weighing hoppers to create the best weight combination in milliseconds, delivering ±0.1 – 3 g accuracy while protecting delicate frozen fillets from bruising. Each precisely engineered hopper dumps only when its load helps hit the target weight, so every gram of raw material ends up in a sellable pack instead of giveaway. With speeds up to 30 packs / min and a 10-inch touchscreen for rapid recipe change-overs, the SW-LC18 turns batching from a bottleneck into a profit centre—ready to integrate with either manual bagging tables or fully automated VFFS and premade-pouch lines.

Final Verdict: Choosing the Perfect Smart Weigh Target Batcher

Choosing a perfect target matcher is a complicated task. However, we have already made it easier for you by giving you all the necessary and minor details you need to see. Now, all you need to do is select whether you are a mid-sized company with lesser packing needs or you want a full-scale, high-speed target batching system that can batch a large number of products.

Depending on your answer, you can either go with a 12-head or 24-head target batcher from Smart Weigh. If you are still confused, you can check out the full product specs at Automation Target Batcher Smart Weigh.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine