Complete Guide To Cannabis Packaging Machine

Cannabis products need safe, clean, and compliant packs. Shoppers want clear labels and fresh goods. Makers want speed and low waste. A cannabis packaging machine helps with all of that. It turns a slow job into a smooth line. It measures, fills, seals, and labels with care.

This guide explains formats, materials, machine types, advantages and key rules. It shares tips to fix common issues. Read on to learn more.

Packaging Formats and Materials

It is important to talk about the most important packaging formats and materials that will keep cannabis products fresh, safe and in compliance.

◆Pouches amd Jars

Cannabis products come in many forms. Flowers, pre-rolls, gummies, and oils all need the right pack. Common formats include:

● Pouches for flower and edibles. They are light and easy to store.

● Jars for premium buds or gummies. They protect shape and smell.

Your cannabis packing machine should support the formats you sell now and in the future.

◆Materials for Freshness and Compliance

The pack's material matters. It preserves aroma, moisture, and potency.

● Multi-layer films block oxygen and light.

● Flavors are kept pure through food-grade plastics and glass.

● The tamper-evident seals indicate whether a pack has been opened.

● Smell control is achieved using odor-barrier films and liners.

● Humidity and oxygen can be controlled by using desiccant packs or nitrogen flush.

Choose materials that match the product and meet the rules. Test shelf life and seal strength before launch. Keep child-resistant ratings in mind during design and trials.

Machine Types for Cannabis Packaging

Once the formats and materials are clear, the next step is to explore the different machines that handle cannabis packaging.

▶Weighing and Filling Machines (Semi-auto)

These machines weigh the product and drop it into jars, pouches, or small containers. Because they’re semi-automatic, a person still controls part of the process. But the machine handles the tricky part, getting the weight just right.

That means less waste and more consistency. Semi-auto models are great for smaller or growing businesses that need accuracy but still want some flexibility for products like flower, gummies and etc.

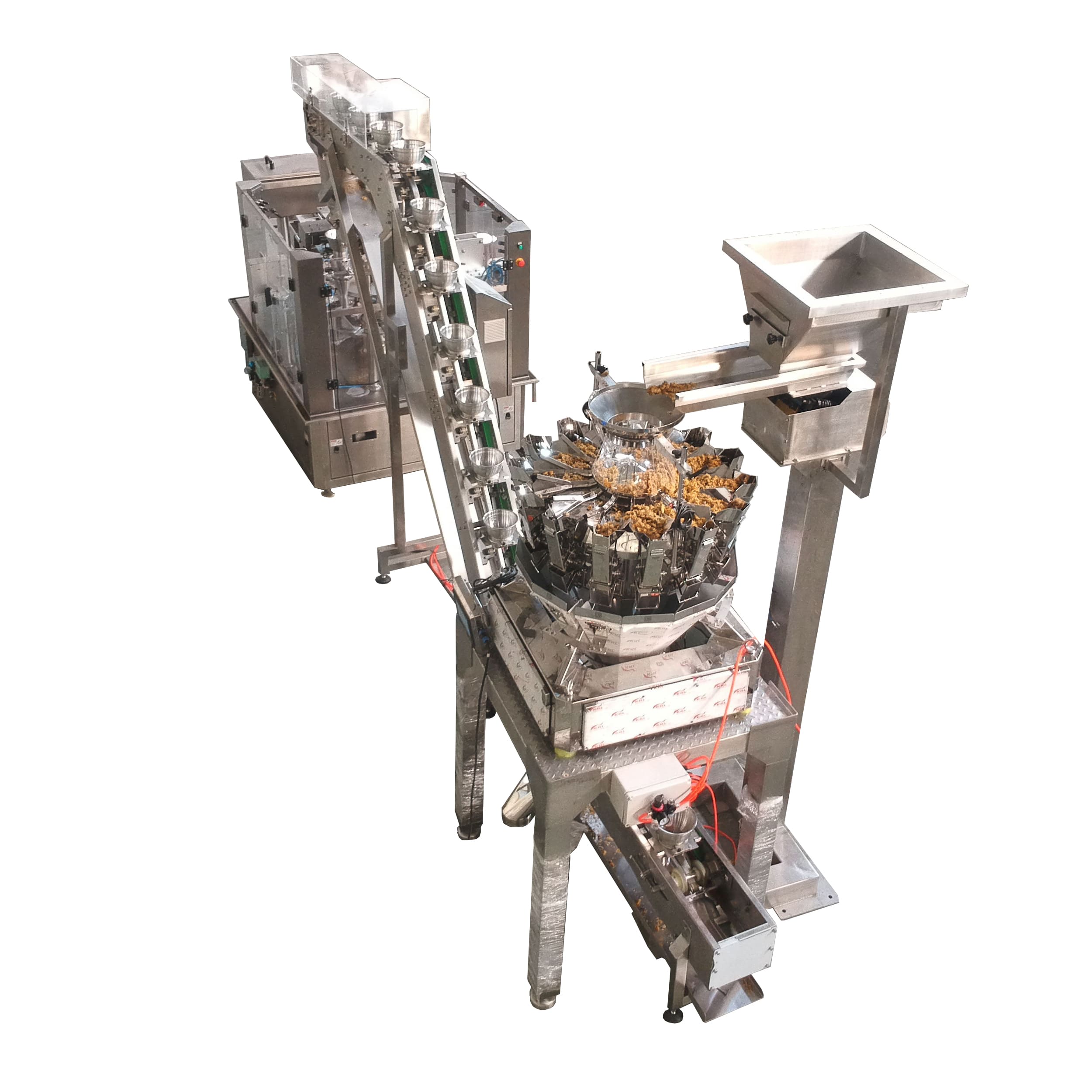

▶Integrated Packaging Systems (Fully-auto)

Fully-automatic systems take care of almost everything. They weigh, fill, seal, and sometimes even label the packages in one smooth line. Once it’s set up, the machine runs on its own with little human help.

This makes it faster, cleaner, and more reliable, which is important for cannabis where rules are strict. Big producers prefer these systems because they save time, reduce labor costs, and keep every pack looking the same.

Advantages of Cannabis Packaging Machines

Now that we've seen the machine types, let's discuss the big advantages they bring to cannabis packaging.

✔1. Efficiency and Accuracy

Speed and accuracy go hand in hand. A cannabis packaging equipment can run long shifts with steady output. It cuts rework and reduces human error. That means more good packs per hour and fewer headaches. Line data helps managers spot issues early and tune the process.

✔2. Compliance with Regulations

Rules can be strict. Good machines help you meet them. Use child-resistant containers and tamper-evident seals. Include labels that contain THC content, ingredients, batch IDs and cautions when necessary. Printers and vision systems can verify data and barcodes. That keeps audits simple. Many lines also log settings and counts for track-and-trace needs.

✔3. Product Safety and Shelf Appeal

Excellent packaging preserves products and makes them attractive. Smooth seals, neat labels and fresh aromas build trust. Clear windows, matte films, or sturdy jars can lift shelf appeal. With repeatable settings, your line delivers the same look every time. Consistent packs help stores stock faster and reduce returns.

Relevant Laws and Regulations

Besides the machines themselves, one should also know the laws and regulations that govern the packaging of cannabis.

▶Labeling Requirements

Most regions require clear, honest labels. Typical items include:

● Net weight and product name

● Ingredients and potential allergens

● THC/CBD content and serving size

● Batch or lot number and dates

● Warnings and age limits where required

Work with your legal team to map the exact list for your market. Review updates often so your labels stay current.

▶Safety and Compliance Standards

Safety rules often cover child resistance, tamper evidence, and sanitation. Use food-grade contact parts and stainless steel frames where needed. Maintain good cleaning and changeover records. Train your team and update SOPs. Routine checks cut risk and keep audits short.

▶Packaging Restrictions in Different Regions

Rules vary. Some areas limit bright colors or shapes that appeal to kids. Others restrict see-through packs or require plain fronts. Many regions also need track-and-trace codes. Always check local laws before a new run. When you sell in more than one region, build a label library to switch designs fast.

Conclusion

A cannabis packaging machine helps brands move faster, stay compliant, and keep quality high. From weighing and filling machines to sealing and labeling machines and integrated packaging systems, you can build a line that fits your goals. Add checks like a checkweigher to cut waste and boost trust. Want to grow with less stress? Solid packaging is a smart place to start.

Ready to upgrade your line? At Smart Weigh Pack, we design reliable cannabis packing machines that speed up work, improve accuracy, and support compliance. Contact us to find the right solution for your business.

FAQs

Question 1. What types of packaging are allowed for cannabis products?

Answer: Rules vary depending on the region. Although pouches, jars and child-lock containers with tamper-evident features are common.

Question 2. How do cannabis packaging machines ensure compliance?

Answer: They support accurate dosing, secure seals, and precise labels. With printers and vision checks, they help meet data and warning rules.

Question 3. Are cannabis packing machines customizable?

Answer: Yes. You can choose fillers, sealers, labelers, and QC tools to match flowers, edibles, oils, or pre-rolls. Change parts make swaps quick.

Question 4. What are the main advantages of automating cannabis packaging?

Answer: You get higher speed, better accuracy, cleaner packs, and easier audits. You also cut labor costs and reduce product giveaway.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine