Everything You Need to Know Before Investing in a Cereal Packaging Machine

A cereal Packaging machine is a must-have machine for the food industry. It’s much needed to increase the shelf life of the product and to make sure the items don’t get damaged. Nevertheless, it’s always needed for premium packaging and to comply with global or domestic standards.

This guide will tell you everything you need to know before investing in a cereal packing machine.

Let’s begin with the definition.

What is a Cereal Packaging Machine?

A serial packaging machine is a dedicated equipment designed to pack different types of cereals. The machine encompasses some of the features needed for cereal packing.

Whether you’re packaging cornflakes, granola, muesli, or puffed rice, a cereal packing equipment helps you in the packing and sealing of these products. The machine does all the work for you, starting from weighing the products and filling them, to sealing and labelling the products.

Why Proper Packaging is Important for Cereals

You need a high-quality packaging machine if you are working with cereals. Here are the reasons.

◆Preserves Freshness

Cereals can lose their freshness if the packaging is not proper. Keeps the cereal crispy and flavorful by protecting it from moisture and air. You need a high-quality packaging machine for the same.

◆Maintains Hygiene

A small hole could lead to dust, pests, and other issues. As the food is to be consumed by your customers, it’s bad for their health as well, and it may invite some legal trouble. So, it’s better to get a dedicated cereal packaging machine with accuracy.

◆Improves Shelf Life

Good packaging will also increase the shelf life of the product. If you are selling globally, it’s much needed. Some cereals don’t sell much. Without proper packaging, even the highest-quality cereal can lose its appeal before it even reaches the store shelves.

◆Brand Image

Clean and attractive packaging catches the customer's eye and builds trust. You can use a premium cereal packaging machine to sell the items at a higher rate. We will talk more about these machine types later in this guide.

◆Accurate Portions

Consistency is the key. The cereal packing equipment also has a weigher that will check the weight and make sure the portions are accurate in each bag. That’s how you can have consistency in your products.

Different Types of Cereal Packaging Machines

While a cereal packing machine allows you to pack all types of cereals, there are many types of cereal packing machines you need to check. Let’s talk about them.

▶Multihead Weigher with Vertical Form Fill Seal Machine (VFFS)

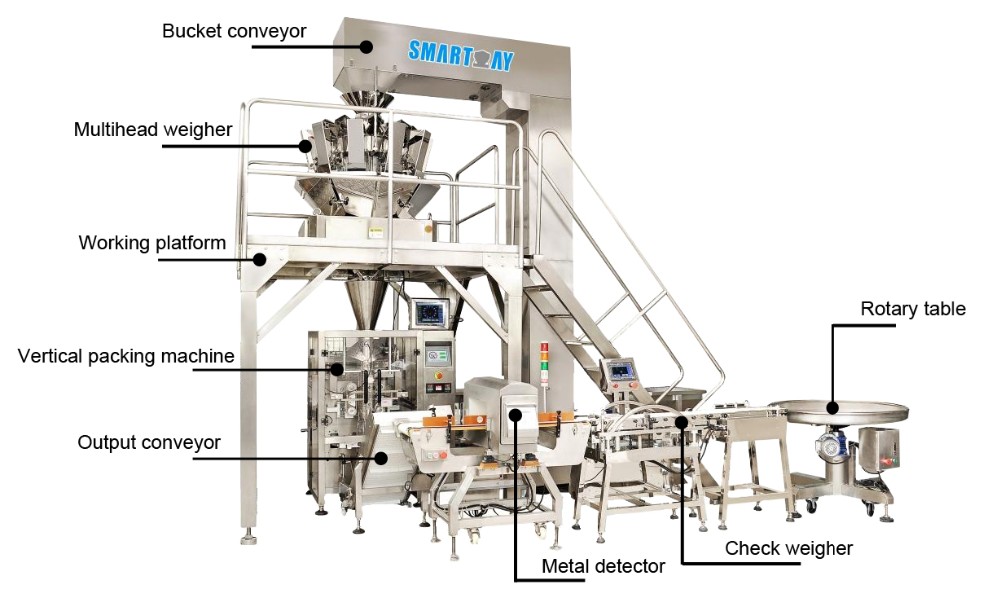

A multi-head machine is highly recommended for high-speed and large-scale operations. VFFS can form a bag from a flat roll of film, add cereal as per the given quantity, and then seal it tightly to increase the shelf life.

Best for: Large production lines packing cereals in pillow bags, gusseted bags, or stand-up pouches.

✔Advantages:

· Extremely fast and efficient

· High weighing accuracy

· Works well with fragile cereals

▶Linear Weigher Cereal Packing Machine

Not a large enterprise and want something a little flexible? Check out the Linear Weigher cereal packing machine. The accuracy and precision are pretty much excellent here. However, the amount of quantity it can handle is limited. So, it’s great for mid-sized businesses.

Best for: Small to medium-scale production or companies just starting.

✔Advantages:

· Lower investment cost

· Simple operation and maintenance

· Good for medium speeds and moderate accuracy requirements

▶Automatic Pouch Packing System for Cereals

For companies that want automation with fewer human interventions, this automatic pouch packing system for cereals will do most of your work with great speed. You will need pre-made pouches here.

Thereafter, it can pick, open, fill, and seal the package automatically. As it’s made for premium usage, you can expect stylish packaging with premium feels.

Best for: Premium or specialty cereal brands that focus on presentation.

✔Advantages:

· High-quality and attractive pouch packaging

· Flexibility to use different pouch styles and sizes

· Ideal for small to mid-size batches of specialty cereals

Factors to Consider Before Investing

Let’s see certain factors you need to consider before you move ahead.

●Check Out the Type of Packaging Machine

You need to assess your production line and packing line to understand if you need a VFFS machine or a small-sized mini machine.

Think about:

· Your current production volume

· Expected growth

· Types of packaging you want (bags, pouches, boxes)

· Budget for the initial investment

●Features of Cereal Packaging Machine

Some important features to look for include:

1.Weighing accuracy to reduce product giveaway

2.Gentle product handling to prevent cereal breakage

3.Speed that matches your production targets

4.Versatility to handle different bag sizes or types

5.Durable construction, ideally stainless steel for hygiene

3.Ease of cleaning to meet food safety standards

Optional features like nitrogen flushing (to extend shelf life) or zip-lock bag capabilities can also be valuable if your brand needs it.

●Long-term and Maintenance Costs

Think about one-time buying costs as well as maintenance costs.

◇Maintenance requirements: Some machines need regular servicing and part replacements. You can see if the parts are removable and cleanable as well.

◇Downtime costs: A complex machine that's difficult to repair can halt production and cause losses.

◇Operator training: Machines that are easy to operate can save you time and training costs. Smart Weigh machines come with an easy touchscreen to manage the.

◇Energy consumption: Energy-efficient machines lower your ongoing operational costs.

Final Verdict: Should You Invest in a Cereal Packaging Machine?

Here’s the final verdict on the cereal packing machine.

★For high-volume: A Smart Weigh multihead weigher with a VFFS machine is the best investment.

★For small to medium businesses: Smart Weigh linear weigher or an automatic pouch system balances cost and performance.

★For premium brands, the Smart Weigh automatic pouch packing system is the only option.

That’s how you can choose the best cereal packaging system based on the above needs. You can see the full list of features on the Smart Weigh website. If you need more help, you can always contact the team for further help.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine