What to Look for When Choosing a Rotary Packing Machine for Your Production Line

Introduction

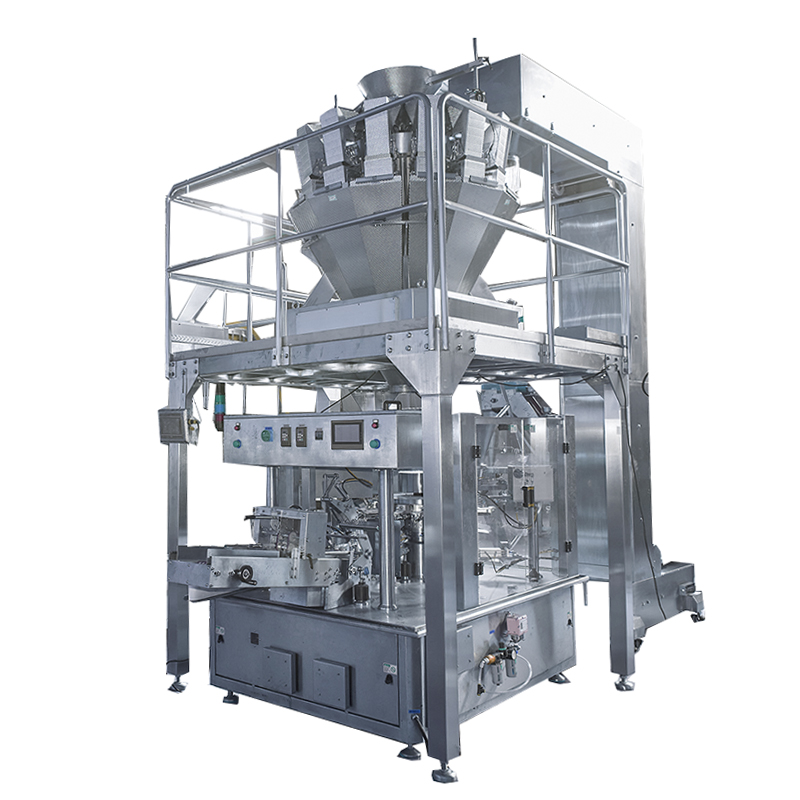

A rotary packing machine is an automated system that enhances high-speed packaging for products like powders, liquids, and granule. These machines operate through a rotating turret with multiple stations performing tasks such as picking up pouches, opening, filling, sealing, and nitrogen flushing synchronised. They are widely used across industries like food, pharmaceuticals, and cosmetics for their efficiency and flexibility.

When choosing a rotary packaging machine, consider factors like production throughput, pouch compatibility, and sealing precision. It is also essential to evaluate the filling system—whether volumetric, auger, or multi-head weigher—and ensure it supports the required pouch types, such as stand-up or zipper pouches.

Features like easy changeovers, CIP (Clean-in-Place) capabilities, and smooth integration with other equipment can further enhance production efficiency. Let’s discuss your business's production requirements.

Your Production Requirements

Rotary packing machines should align with your production scale and objectives. Identify whether your operation involves high-speed packaging or small-batch runs, as different machine models—like simplex or duplex—offer varied levels of throughput and flexibility. This assessment ensures optimal equipment performance and cost efficiency.

●Production Speed and Volume Needs

Automatic rotary pouch packing machine excel in fast, continuous operations, with speeds reaching up to 80 bags per minute depending on the model and product type. Machines such as duplex models are tailored for high-volume production, making them ideal for businesses needing rapid throughput without compromising precision.

●Product Type and Packaging Style

Automatic rotary pouch packing machines' versatility allows them to handle liquids, powders, or solids with ease. They support various packaging styles, including stand-up, flat, and zipper pouches, meeting the requirements of diverse industries, from food to pharmaceuticals.

●Material Handling Capabilities

Modern rotary pouch packing machine is able to integrate advanced material handling machine, such as multi-head weigher and auger filler, ensuring consistent accuracy. Additionally, features like pouch presence detection prevent material waste by stopping the process if a pouch is missing, further enhancing production efficiency.

Quality and Accuracy of Packaging

The quality of packaging directly influences product integrity and consistency throughout production. Precision filling and sealing prevent underfilling, spillage, or contamination, which is essential for customer satisfaction and regulatory compliance. Rotary packaging machines stand out for their ability to accurately fill and seal products at high speeds.

◆Sealing and Filling Precision

Sealing precision ensures the product remains protected from environmental factors like air and moisture. Rotary machines with advanced sealing technologies, such as temperature-controlled sealing heads, create airtight seals to maintain quality and reduce waste. Filling precision is also critical; for example, accurate metering minimizes discrepancies in product quantity, which is especially important for items like powders, oils, or liquids to maintain uniformity across packaging batches.

◆Impact on Product Shelf Life and Freshness

A well-sealed package is vital in extending product shelf life by limiting exposure to oxygen and moisture, which can lead to spoilage. Rotary machines designed for vacuum sealing can significantly delay bacterial growth and oxidation, preserving product freshness for longer periods. This capability is particularly beneficial for food, cosmetics, and pharmaceutical products, where freshness is a top priority during storage and distribution.

Automation Features

Automation in rotary pouch filling machine improves efficiency, accuracy, and throughput, making it crucial for production lines seeking higher productivity. Modern systems incorporate advanced technologies like continuous rotary motion, which eliminates downtime and enhances consistency in operations.

✔User-Friendly Interface and Controls

A key aspect of automated packaging machinery is its intuitive interface. These machines are designed with user-friendly control panels, often incorporating touchscreens and customizable settings. This makes it easier for operators to adjust parameters quickly, reducing the learning curve and potential operational mistakes.

✔Level of Automation

Rotary packing machines vary in automation levels, from semi-automatic systems to fully automated lines. Fully automated models optimize productivity by integrating seamlessly with conveyors and other equipment, minimizing human intervention throughout the process. Such machines are especially useful in high-volume industries.

Machine Footprint and Space Requirements

The physical size of a rotary pouch packing machine impacts how well it fits into your production environment. Manufacturers must also evaluate modular or customizable designs to ensure flexibility and future scalability.

●Physical Dimensions of the Machine

The size of a rotary pouch filling machine directly impacts production floor planning. Compact models allow easier integration into existing lines without disrupting workflows, while larger machines may require custom layouts.

●Modular or Customizable Designs

Modular designs offer flexibility by enabling manufacturers to adapt the machine for different products or packaging needs with minimal disruption. This adaptability makes it easier to introduce new products without replacing the entire system, ensuring scalability and smooth operation with changing production demands.

Speed and Downtime Management

Managing speed and downtime is essential for maintaining efficiency. Machines with high CPM (cycles per minute) and fast changeovers help minimize disruptions and keep production flowing smoothly.

◆Machine Speed

Running speed, typically measured in pouch per minute (PPM), is a critical performance indicator. Higher PPM rates are essential for high-volume operations, but maintaining precision at such speeds can be challenging. Some machines achieve speeds up to 45 PPM, striking a balance between speed and quality to meet production goals efficiently.

◆Changeover Times and Flexibility

Fast and efficient changeovers are crucial for minimizing downtime, especially when switching product types or packaging formats. Newer machines support streamlined changeovers through automated systems and intuitive human-machine interfaces (HMIs), significantly reducing manual adjustments.

Compliance with Industry Standards

Rotary packaging machines must adhere to strict industry regulations to ensure safety, efficiency, and sustainability. Compliance with food, electrical, and environmental standards is vital to meet legal and operational requirements.

▼Food Safety Standards and Certifications (HACCP, FDA, GMP)

Packaging machines used for food products must align with standards like HACCP, FDA guidelines, and Good Manufacturing Practices (GMP). These frameworks ensure that production environments minimize contamination risks and maintain product quality throughout the process, essential for regulatory approval and customer trust.

▼Electrical and Mechanical Safety Compliance (CE Marking, ISO Standards)

Rotary machines need to meet ISO and CE marking requirements to ensure both operational safety and reliability. These certifications cover electrical, mechanical, and operational safeguards, reducing hazards during machine use and maintenance.

▼Environmental and Energy Efficiency Standards

Modern rotary machines must meet environmental standards for energy efficiency and waste reduction. Certifications such as FSSC 22000 emphasize sustainability in packaging processes, promoting the responsible use of materials and energy while maintaining food safety.

Conclusion

When selecting a rotary packing machine for your production line, it is essential to evaluate factors such as speed, precision, and compliance with industry standards. Machines like the SW-8-200 8-station rotary packing machine ensure consistent filling and sealing while meeting the regulatory demands of sectors like food and pharmaceuticals. These machines streamline operations, enhancing both efficiency and product quality.

For optimal results, choose a reputable manufacturer such as Smart Weigh offers advanced solutions like theSW-8-200 automatic rotary packing machine. With their focus on customizable designs and energy-efficient operations, Smart Weigh Pack machines are tailored to meet a wide range of packaging needs while maintaining high standards of performance and sustainability.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine