What to Look Out for When Purchasing a Rotary Pouch Packing Machine?

If you were to get a rotary pouch packing machine, here are a few things that you need to look for. These are the most important yet often ignored things that most people don’t consider.

Keeping these factors in mind will help you to give maximum accurate results. In simple terms, you will have premium quality packing and precise weighing across the products.

What Products Work Best with Rotary Pouch Machines?

There are multiple types of products that work best with rotary pouch machines.

●Snacks like chips, nuts, or dried fruits

●Frozen foods such as dumplings, vegetables, and meat cubes

●Granules and powders like sugar, coffee, or protein mixes

●Liquids and pastes, including sauces, juices, and oils

●Pet food in chunks or kibble form

Due to their flexible design and accurate filling options, these rotatory pouch machines are good for any type of business. As you can see, most of the products are supported in this machine.

You still need to look at certain factors before you buy a rotary punch machine. Let's take a look at it.

What to Look Out for When Purchasing a Rotary Pouch Packing Machine?

While you don’t need to look at many things while getting a rotary pouch filling machine, you need to keep in mind some of the mandatory and crucial factors. Let’s cover the same.

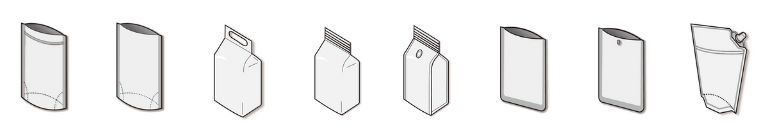

◆Pouch Types the Machine Can Handle

While the pouch machine supports maximum food items, there are limitations on the types of pouches it can manage. Here are a few pouch types it can handle.

▶Stand-up pouches

▶Zipper pouches

▶Flat pouches

▶Spout pouches

▶Premade Quad seal or gusseted pouches

You need to understand your requirements and see what types of pouches your company is working with.

◆Accuracy of Filling

The filling system is the heart of a rotary packaging machine, and its performance directly affects product quality and cost efficiency. Different products require specific filling technologies:

1.Granules/Solids: Volumetric fillers, multi-head weighers, or combination scales.

2.Powders: Auger fillers for precise dosing.

3.Liquids: Piston or peristaltic pumps for accurate liquid filling.

4.Viscous Products: Specialized fillers for pastes or gels.

5.Accuracy: High-precision filling minimizes product giveaway (overfilling) and ensures consistency, which is critical for customer satisfaction and cost control.

6.Product Compatibility: Confirm the machine can handle your product’s properties, such as temperature sensitivity, abrasiveness, or stickiness. For example, hot-fill products (e.g., sauces) require heat-resistant components, while fragile products (e.g., snacks) need gentle handling.

7.Anti-Contamination Features: For food or pharmaceutical applications, look for hygienic designs with minimal product contact surfaces and anti-drip or dust-control systems.

◆Speed, Efficiency, and Production Rates

If you're scaling your operations or handling large volumes, speed and efficiency should be top priorities. Different machines offer different speeds, usually measured in pages per minute (PPM). Rotary machines often offer 30 to 60 PPM. It also depends on various factors such as product and pouch type.

Do not compromise on accuracy and sealing while looking for speed.

◆Flexibility to Handle Different Products

As we mentioned above, the rotary powder machine supports various products. Some machines only allow limited products, while some allow a variety of pouch packing.

Therefore, do not forget to check out the flexibility to handle different products. Choose a system that can switch between powders, solids, and liquids with simple adjustments or tool-free part changes.

◆Easy Cleaning and Maintenance

It goes without saying that for all the machines, make sure the rotary pouch filling machine is easy to clean and maintain.

By maintaining, you also need to see if the parts and components are available, and you can maintain the system at a minimum cost. Removable components will help you a lot in cleaning and maintenance. Maintenance features like self-diagnostics, alerts, and easy access panels also help catch minor issues before they become major problems.

◆Machine Size and Space Requirements

Make sure the machine fits within your facility's layout. Some rotary packaging machines are compact and designed for smaller production areas, while others are larger and better suited for full-scale factory operations.

If you get a smaller machine, the number of products it can handle decreases. So, analyze all those things before buying one.

Filtering the Right Pouch Packing Machine

Let's filter out and find you some of the best rotary pouch machines.

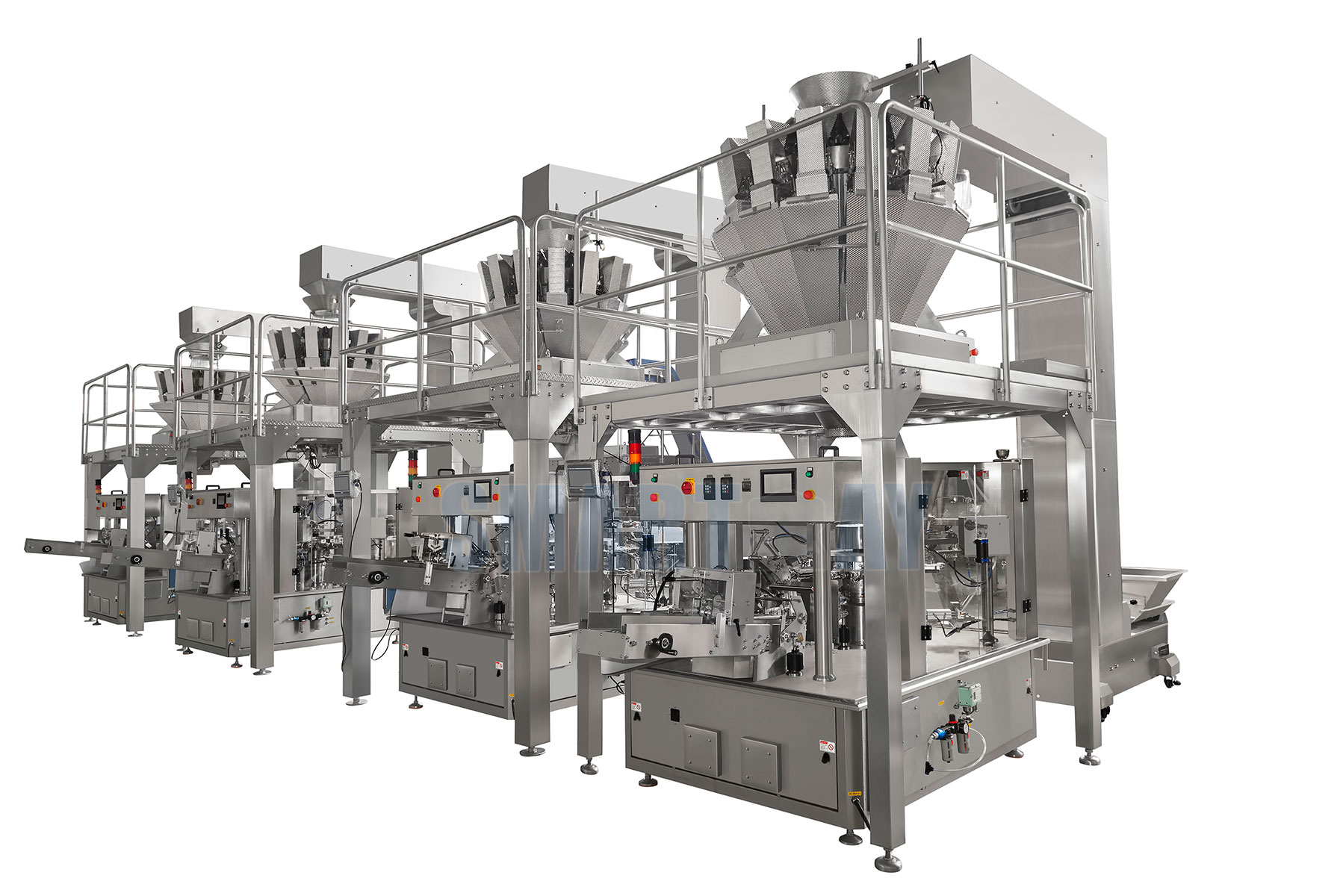

✔Smart Weigh 8-Station Rotary Pouch Packing Machine

This Smart Weigh 8-station rotary pouch packing system comes with 8 operational stations. It can fill, seal, and even level the pouches.

Highly recommended for mid-sized companies, each of these stations handles different operations. Mainly, it allows you to perform pouch feeding opening, filling, sealing, and even discharging when needed. You can use this machine for food items, pet food, and even some non-food items, where you need to do all these tasks.

For easy maintenance and operations, Smart Weigh offers a touch screen to ensure quality control.

✔Smart Weigh Rotary Vacuum Pouch Packing Machine

This machine is perfect for products that need an extended shelf life.

As the name suggests, it uses a vacuum system to remove excess air from the pouch before sealing, which keeps products fresher for longer.

So, if your product requires a high shelf life, this is the perfect machine for you. To be more specific, it’s ideal for meat, seafood, pickles, and other perishable goods.

The system is fully automated with proper accuracy in weighing and sealing.

✔Economic Option: Smart Weigh Mini Pouch Packing Machine

You can use the Smart Weigh Mini pouch packing machine if you are a small business looking to add a pouch machine to your packing line.

Despite its compact design, the performance is amazingly good with accurate speed and control.

It can easily handle small to medium quantities of products. Startups, small food brands, and others can use it due to its small design. If your factory has limited spacing, this is the go-to option for pouch packing.

Conclusion

While getting a rotary pouch packing machine, you first need to understand your production needs and then see the accuracy and precision of the machine. Thereafter, you can see if the machine allows your food type. Smart Weigh is the perfect option that fulfills all these and is available in all sizes.

You can learn more about these options or get in touch for a custom recommendation at Smart Weigh Pack.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine