What You Need To Know About Laundry Pod Packaging Machine

Laundry pods have become a go-to choice for clean, simple, and mess-free washing. But ever wonder how they’re packed so neatly? It’s all thanks to laundry pod packaging machines. Smart Weigh Pack offers two main types: rotary-type for doypack and linear-type for container package.

The rotary packing machine uses a circular motion to fill and seal premade doypack bags quickly and with great accuracy. It’s perfect for fast, high-volume production.

The linear machine arrangement for container works in a straight line and is more flexible. It can accommodate different shapes and sizes of pod containers and can work well in a factory with varied packaging needs.

These two machines are used to simplify the work as they automate weighing, filling, and sealing. This article will explain how these laundry capsule packing machines work, where they have been used and why they are a good investment for anyone with a business in detergents or home care. Read on to learn more.

How Laundry Pod Packaging Machines Work

Laundry pod packing machines are designed to handle pre-made detergent pods and pack them into bags, tubs, or boxes quickly and neatly. Whether it’s a rotary or linear layout, the goal is the same: fast, clean, and accurate packaging. Here's how it works:

◆Rotary-Type Packaging Workflow

Rotary systems are built around a circular motion, making them ideal for high-speed operations with steady output.

· Pod Feeding: Pre-made laundry pods are loaded into the machine's feeding system.

· Counting or Weighing: Smart sensors count or weigh the pods, making sure each pack has the exact amount.

· Bag Opening and Filling: The machine opens a premade bag (such as a doypack) and then fills it with pods using a rotating carousel system.

· Sealing: The bag is sealed tightly to keep the pods secure and fresh.

· Discharge: Finished packages are sent down the line, ready for labeling, boxing, or shipping.

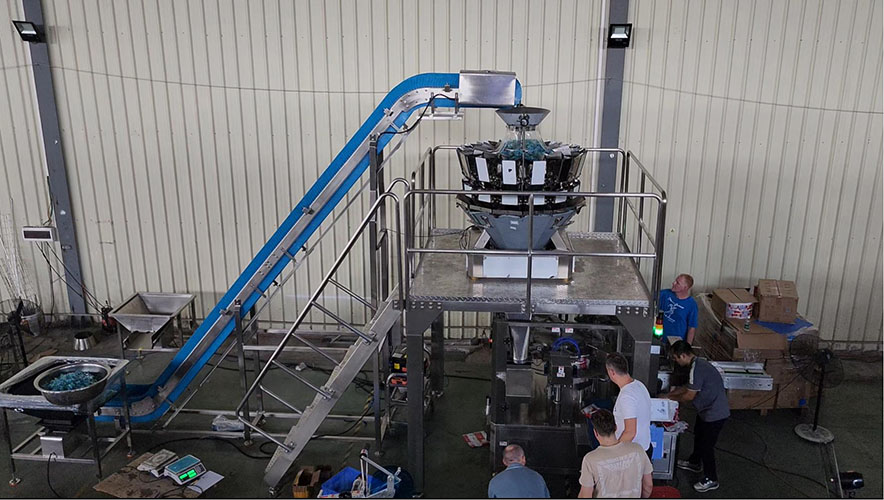

◆Linear-Type Packaging Workflow

Linear systems move in a straight line and are often used when flexibility and customization are needed.

· Pod Loading: Pre-formed pods are placed onto the line via hopper or conveyor.

· Accurate Dispensing: The system counts or weighs the pods with high precision.

· Pod Filling: Connects with weigher, fill pods into containers.

· Heat Sealing: The top of each container is sealed.

· Finished Container Discharge: Packed containers move off the line for further processing or shipping.

Both types of systems keep your packaging clean, safe, and efficient. And because Smart Weigh Pack focuses on high-end automation, our machines handle detergent pods of various sizes and packaging styles without the mess or fuss.

Applications in Detergent and Home Care Packaging

You guessed it, these machines aren’t just for laundry pods! Their versatility makes them a smart pick for packaging various home care products.

✔Main Applications:

● Laundry Detergent Pods: Liquid-filled, single-use packs

● Dishwasher Pods/Tablets: For automatic dishwashers

● Toilet Cleaning Pods: Pre-measured solutions

● Fabric Softener Pods: Small softening agents

● Dishwashing Capsules: Both for home and commercial kitchens

Due to their flexibility, laundry capsule packing machines are being utilized across various cleaning and personal care products. With the right sealing and film type, you can even package dual-chamber pods that combine different liquids in one pod. That’s innovation in your pocket!

Automation Benefits and Efficiency

Why are more companies switching to laundry pod packing machines? It all comes down to three big wins: speed, safety, and savings. Let’s break down the benefits:

▶High-Speed Output

The highly advanced machines can weigh, fill, and seal more than 50 packages each minute. It is lightning quick compared to doing it manually. You get thousands of pods made in just an hour. This means more products on the shelves and happier customers.

▶Perfect Accuracy, Every Time:

Every pod comes out just right, same size and the same fill. No guesswork. No waste. This is a way of saving money and maintaining the quality of your product. With detergents, it is particularly important because too little or too much can spoil the wash.

▶Less Waste = More Profit:

These are the machines that use water-soluble film, thus no need to have additional plastic wraps or cardboard boxes. This reduces waste, products and expense. Plus, it’s better for the planet, a win-win.

▶Fewer Hands Needed:

You don’t need a big team to run the machine. One or two trained workers can handle it with ease. This helps save on labor costs and makes your team more productive.

▶Cleaner, Safer Process:

Spills and leaks? Not with these machines. The closed system keeps everything tidy, which is a big deal when handling strong cleaners. It also means better safety for your workers and a cleaner production line.

▶Consistent Quality Control:

Machines don’t get tired. They follow the same process every time. You don’t have to worry about mistakes due to fatigue or distractions. The result? A steady stream of high-quality pods.

▶Easy Maintenance and Monitoring:

Smart features like alarms and touchscreen warning let you know when something needs attention. No need to shut everything down or guess what’s wrong, just fix and go.

Think about it: more pods, fewer errors, less labor, and better hygiene. That’s automation at its best!

Smart Weigh Pack’s Capabilities

Now let’s talk about Smart Weigh Pack, the company behind these powerful machines.

▲1. Advanced Design for Efficiency: Our machines are designed for high-speed output without compromising on accuracy. Whether you need a rotary-style model or a linear setup, Smart Weigh offers options to fit every type of production line.

▲2. User-Friendly Control Panels: The user-friendly touchscreen control panels make life easier on the floor. With a few taps, it is possible to adjust settings, switch between products or control its performance and say goodbye to stress and misunderstandings.

▲3. Custom Solutions: Need a laundry packing machine that can make dual-chamber pods or handle special shapes? We offer fully customized options. We provide flexible, tailor-made solutions to fit your business demands.

▲4. Global Support: Smart Weigh Pack’s systems are trusted in over 50+ countries worldwide. We provide excellent support for every machine. Whether it is the installation assistance and training of the operators or fast technical support and availability of the spares, we have got you covered.

▲5. High-Quality Materials: They are made with food-grade plastic and stainless steel, which ensures that they are durable, hygienic, and simple to clean. They are basically durable and grow with your business.

Conclusion

A laundry pod packaging machine may seem like just another tool, but it’s actually the heart of your production line if you’re in the detergent or home care business. Whether you’re packaging detergent pods, dishwashing capsules, or fabric softener units, this machine brings speed, precision, and cleanliness to your workflow.

Smart Weigh Pack’s machines go a step further with customization, easy integration, and global support. So, if you’re ready to step into the future of home care packaging, this is the machine to watch.

FAQs

Question 1: What types of pods can be packed with these machines?

Answer: Smart Weigh’s laundry pod packing machines are designed to handle liquid-filled finished pods (like detergent capsules). They are not intended for packaging dry powders or tablets.

Question 2: Can one machine handle different types of containers or bags?

Answer: Yes! The machines are compatible with pouches, doypacks, plastic tubs, and other containers. You can even switch between formats with minimal downtime, making it great for different product lines.

Question 3. What production speeds can be expected?

Answer: It depends on the package type machine type. Rotary pouch packing machine line can reach up to 50 pouches per minute, while container packing line generally 30-80 containers per minute.

Question 4. Is operator training required for daily use?

Answer: Yes, but it’s pretty simple. Most Smart Weigh machines come with easy-to-use interfaces and training support to help operators run them confidently.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine