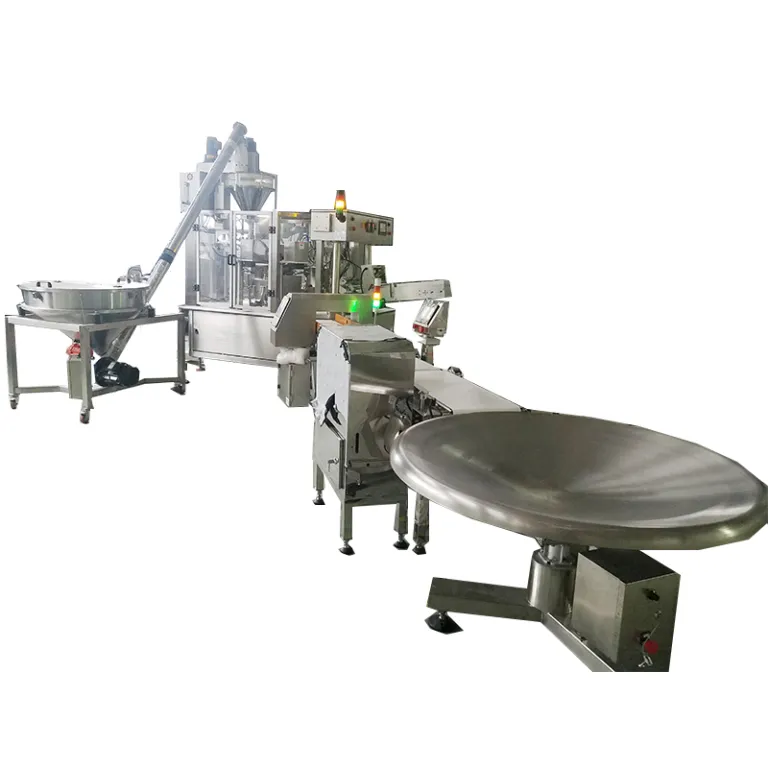

Automatic 1kg 5kg VFFS Vertical Bag Rice Packing Machine

Smart Weigh's rice packing machine consists of VFFS packing machine with 14-head multi-head weigher and anti-leak feeding device, suitable for weighing small particles. 5kg rice stable in 30 packs per min. rice bagging machine fast packaging, cost-effective, less space occupation. Servo pull film, accurate positioning without deviation, good sealing quality.

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

More Choices

Automatic VFFS Vertical Bag Rice Packaging Machine

The Advantages Of Using Rice Packing Equipment

1. It increases your production capacity

A rice packing machine can pack a lot of rice in a short amount of time. This means that you can produce more rice in a day, which increases your overall production capacity.

2. It saves your time and effort, reduces labor costs at the same time

It's faster and more efficient than manual packing. Manually packing rice is a slow and tedious process. The machine is much faster and more efficient, and it requires less labor.

3. More accurate

A rice bagging machine with VFFS packing machine is more accurate than manual packing. This means that you'll be able to pack the right amount of rice into each bag, which can help to avoid waste. We have done the testing, 3kg rice accuracy is ± 3 grams. It means that the final weight range is from 2997 grams to 3003 grams.

4. More consistent

Machine for packing rice in bags is more consistent than manual packing. This means that your rice will be packed the same way every time, which can help to improve the quality of your product.

5. Easier to use

A rice pouch packing machine is easier to use than manual packing. This means that you'll be able to get started using it right away, without having to learn how to use it. After machine installation and parameter settings, click the "RUN" bottom to start your production in the morning and "STOP" bottom to end the production in the afternoon.

6. More reliable

This means that you can rely on it to pack your rice properly, without having to worry about it breaking down, even rice packing machine price.

7. It requires less maintenance

Requires less maintenance than manual packing. This means that you won't have to spend as much time and money on maintaining it.

8. It's more affordable

A rice filling machine with vertical packing machine is more affordable than manual packing. This means that you'll be able to save money on your overall packaging costs.

Application

This rice packaging line is mainly for rice and white sugar, or other tiny granule. It can make the pillow bag, gusset bag from roll film.

The Differences Between Smart Weighpack's Rice Weighing And Packing Machine And Other Machines

This packing machine is designed for portable rice pack with fast speed, such as 1kg rice packing machine, 5 kg rice packing machine. When the machine pack 3kg rice, stable performance is 30 packs per min, accuracy is ±3 grams. Besides, we can provide vacuum device, punch hole device as optional to meet different requirements.

You could see our below machine details to know more about this high speed rice packaging machine. If you are looking for lower speed rice filling machine with multihead weigher, please check here.

Machine Details

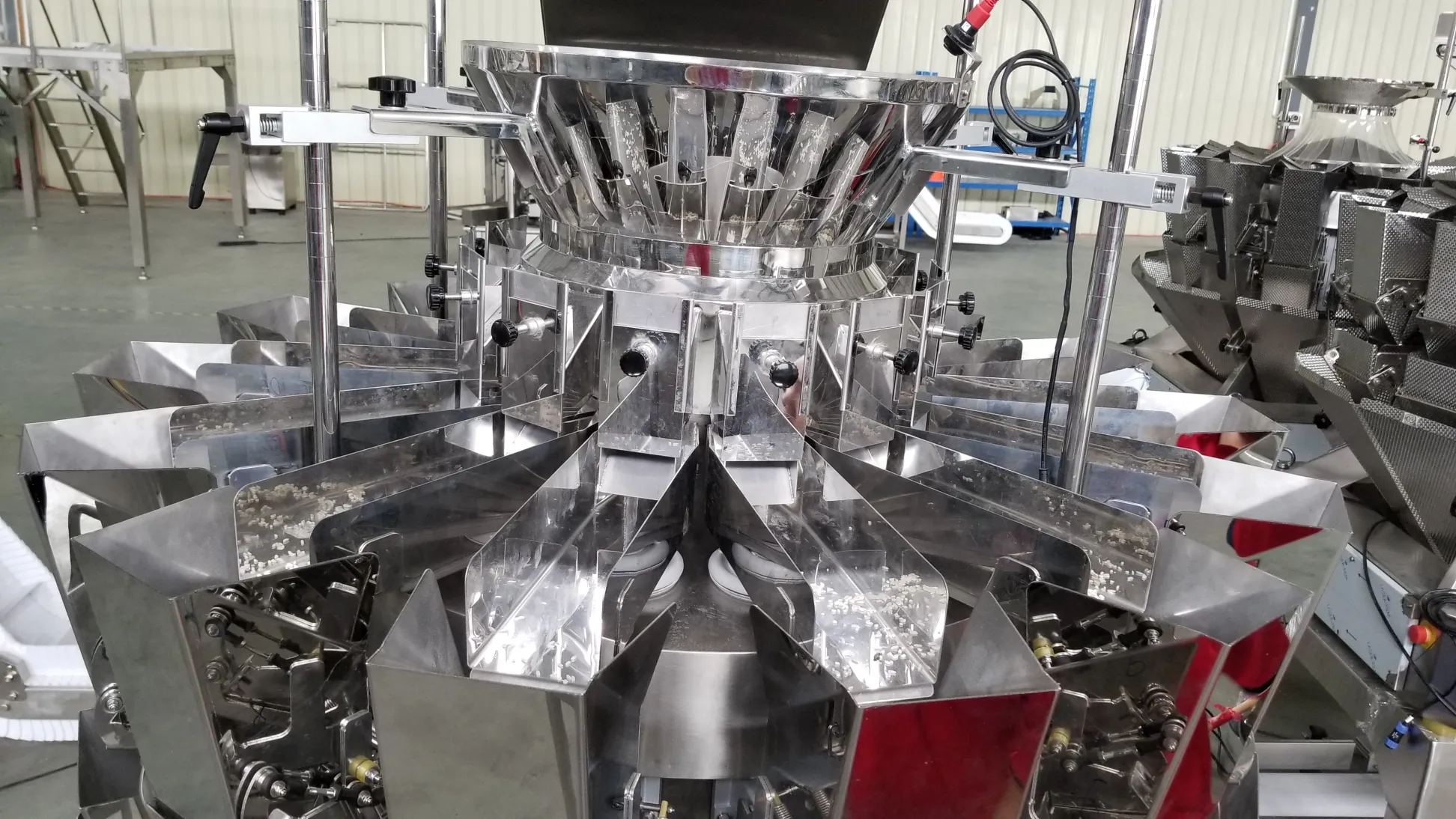

1. Anti-leak feeding device

2. Deep U type feeder pan

3.Anti-leak hopper

Suitable for weighing small particles such as rice, sugar, coffee beans, etc.

VFFS packaging machine, fast packaging, cost-effective, less space occupation.

Servo pull film, accurate positioning without deviation, good sealing quality.

Specification

Weighing Range | 500-5000 grams |

Bag Size | 120-400mm(L) ; 120-350mm(W) |

Speed | 10-30 bags/min |

Bag Style | Pillow Bag; Gusset Bag |

Bag Material | Laminated film; Mono PE film |

Film Thickness | 0.04-0.09mm |

Speed | 20-100 bags/min |

Accuracy | + 0.1-1.5 grams |

Weigh Bucket | 3L |

Control Penal | 7" or 10.4" Touch Screen |

Air Consumption | 0.8Mps 0.4m3/min |

Power Supply | 220V/50HZ or 60HZ; 18A; 3500W |

Driving System | Stepper Motor for scale; Servo Motor for bagging |

Machines List

1) Z Bucket Conveyor

2) Multihead weigher

3) Supporting Platform

4) Vertical Form Fill Seal Machine

5) Output conveyor

6) Metal Detector (OPTION)

7) Check weigher (OPTION)

8) Collect Table

Working Steps

1) Filling products on vibrator of Z bucket conveyor on floor;

2) Products will be lifted on the top of multihead machine for feeding;

3) Multi head weighing machine will automatic weighing according to preset weight;

4) Preset weight products will be dropped to VFFS machine for bag sealing;

5) Finished package will be outputed to metal detector, if with metal machine will alarm, if not will go to check weigher;

6) Product will be passed through check weigher, if over or less weight, it will be rejected, if not, pass to rotary table;

7) Products will get to rotary table, and worker put them into paper box;

Turnkey Solutions Experience

Exhibition

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Quick Link

Packing Machine