Automatic Tin Can Packaging Machine

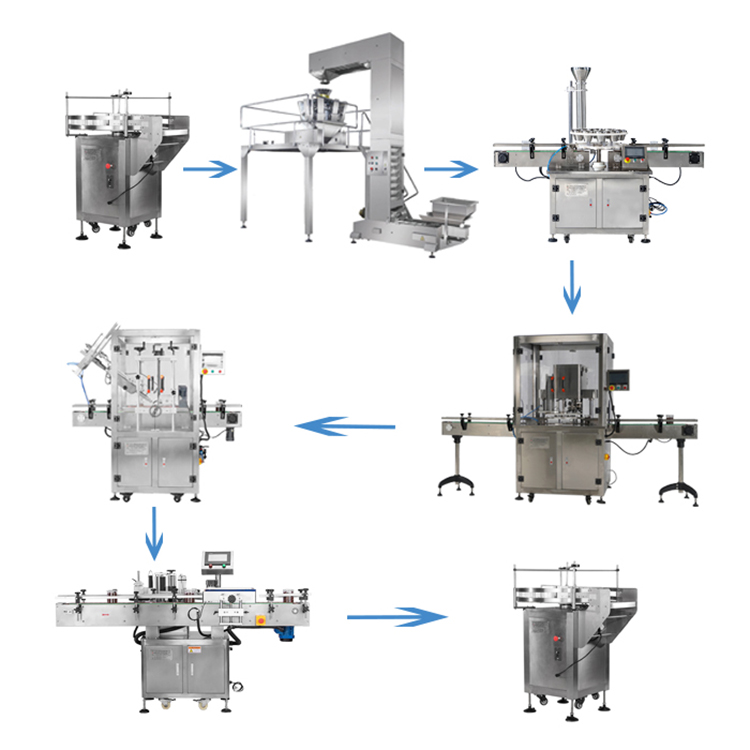

Smart Weigh offer tin can packaging machine from the efficient feeding conveyor to the precise multihead weigher, the innovative rotary type can feeder, the airtight seaming machine, the versatile lid capping machine, the meticulous labeling machine, and the final collecting machine, this system offers unparalleled efficiency, precision, and quality control.

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

More Choices

Tin can packaging has been a staple in the food and beverage industry for decades. It's a method that has stood the test of time, providing a durable and cost-effective way for various food preservation and transport. With the advent of modern technology, tin can packaging machines have taken this traditional method to new heights, offering efficiency, precision, and sustainability. It has became a wise invest for food processors.

At Smart Weigh, we are not only provide the single automatic tin can sealing machine or can labelling machines, but also offer the complete solution for different types metal tin cans. Let's take a look at how many machines the tin can packing line consists of:

*

* 2. Multihead Weigher

Feed conveyor delivers bulk products to multihead weigher, then multihead scale start to weigh and fill. Our multi head weigher features:

* IP65 waterproof, use water cleaning directly, save time while cleaning;

* Modular control system, more stability and lower maintenance fees;

* Production records can be checked at anytime or download to PC;

* Load cell or photo sensor checking to satisfy different requirements;

* Food contact parts disassembling without tools, which is easier to clean;

* Multi-languages touch screen for various clients, English, French, Spanish, etc.

3. Rotary Type Can Feeder

This device is installed under the multihead weigher, it is used for deliver and locate the empty tin cans which is ready for filling. For small materials at the mouth of the tank, the filling rotary table has multiple stations to buffer and synchronously vibrate when feeding, which can increase the filling speed and prevent material blocking.

* Filling diameter φ40 ~ φ130mm, applicable height 50 ~ 200mm (customized according to jar size)

* Production efficiency is about 30-50 cans per minute;

* The overall appearance material is mainly made of stainless steel 304 with a thickness of 1.5mm;

* The chuck and hopper need to be replaced to change the feeding diameter, and the replacement and debugging time is about 10 minutes;

* Change the jar height, no need to change the accessories, just shake the hand wheel, the range is controlled from 50-200mm, and the adjustment time is about 5 minutes;

* Control panel: 7-inch LCD display.

4. Tin Can Seaming Machine

Can seaming machine, also known as a can sealer, is a piece of industrial equipment used to seal the foil lid of a can to its body. It ensures that the contents of the can are kept airtight and free from contamination, optional for Special nitrogen flush.

* High volume Fully-automatic single head seam;

* Adjustable production capacity,seam Up to 50 cans/minute;

* Perfect for sealing tin, aluminum, PET or other paper cans with a maximum diameter of 130mm;

* 2 or 4 seaming rollers for consistent & leak-proof seam.

5. Plastic Top Lid Capping Machine

A lid capping machine, known simply as a capping machine, is a device used in various industries to apply and secure plastic caps or lids onto containers such as bottles, jars, cans.

* It can loading lots of lids and auto separate one by one for capping onto the top of can;

* Custmized design for different kind of lids;

* 7' Touch screen & Mitsubishi control system for more stable running;

* Stainless steel 304 frame suitable for food grade industries.

6. Horizontal Round Can Labeling Machine

It applies to labeling of various round bottles that can not stand up. Such as: oral liquid bottles, ampoules, syringes bottles, batteries, ham, sausage, test tubes, pen, lipstick, solid plastic bottles.

* Main body is made by SUS304 stainless steel & processing by anode of aluminum metal.

* Touch screen control panel, easy operating, included 50-suite memory unit.

* Can configure code printer, accomplishing function of labeling and coding at the same time.

7. Tin Can Collecting Machine

In conclusion, the Automatic Tin Can Packaging Machine from Smart Weigh represents a comprehensive solution for the food industry, encompassing every stage of the packaging process. From the efficient feeding conveyor to the precise multihead weigher, the innovative rotary type can feeder, the airtight seaming machine, the versatile lid capping machine, the meticulous labeling machine, and the final collecting machine, this system offers unparalleled efficiency, precision, and quality control.

If you're looking to elevate your packaging line, reduce costs, and ensure the highest standards of quality and sustainability, Smart Weigh's Tin Can Packing Machine is the solution you've been searching for. Don't miss the opportunity to transform your production line with this high-tech system. Contact us now to learn more and take the first step towards a more efficient and profitable future.

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Quick Link

Packing Machine