Automating Your Packaging Line: A Step-by-Step Guide for Growing Businesses

Key Takeaways

If you see production bottlenecks and quality problems, it's time to automate your packing activities.

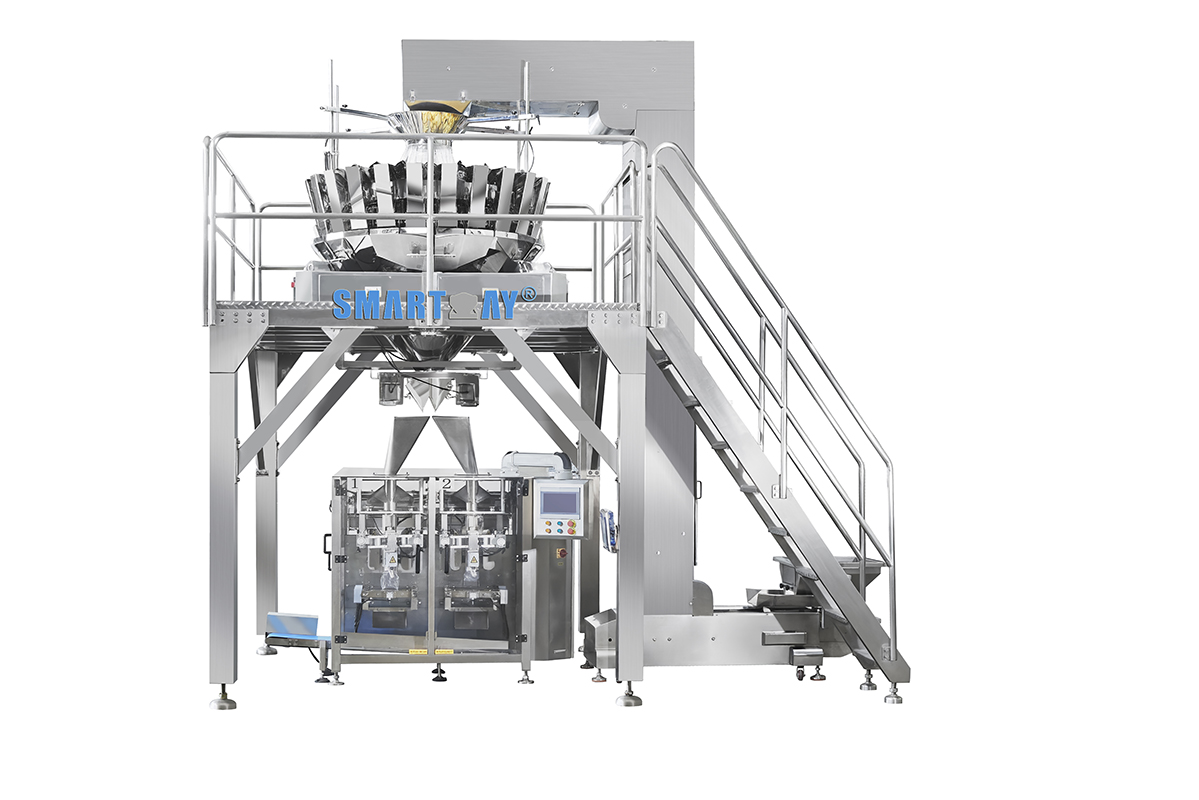

● Smart Weigh's modular multihead weighers and VFFS systems let you automate slowly without stopping existing production.

● Integrated packaging lines that include weighers, baggers, and inspection systems are the most efficient and safe for food.

● Smart Weigh's tiny footprint machines let you make the most of your factory floor area by arranging the layout correctly.

● Using Smart Weigh technology to automate tasks lowers personnel expenses, cuts down on giveaways, and guarantees a steady return on investment through dependable performance.

Food firms that are growing have a tough choice to make: keep battling with hand packing or switch to automation that grows with success. Smart Weigh's integrated packaging solutions make this change easy, especially for businesses that are just starting to use automated production.

Know When Your Production Needs Smart Weigh Automation

If your packing line is having problems with irregular portion weights, production delays, and finding enough workers, it's time to upgrade. When weighing by hand slows things down or giving away too much stuff, it's time to use multihead weigher technology.

Smart Weigh's method is different from that of most other automation companies. Our modular solutions work with your existing equipment, so you don't have to completely change your lines. This lets you make strategic modifications that have an immediate effect on your bottom line.

Begin with Reliable Multihead Weigher Technology

Accurate, high-speed weighing is the first step on your path to automation. Smart Weigh's multihead weighers provide accurate portioning while keeping speeds that manual systems can't match.

There are standard 10-head units for smaller businesses and big 24-head systems for big production lines. Each weigher has touchscreen controls and can store recipes so you can quickly switch between products.

Choose Integrated Systems That Grow with Your Business

If your packing line is having trouble with production delays, irregular portion weights, and hiring workers, it's time to upgrade it. Multihead weigher technology is needed when manual weighing slows things down or product giveaway goes above the limit. Smart Weigh's strategy is different from that of standard automation suppliers since they offer modular systems that work with your current equipment. This lets you make smart modifications that have an immediate effect on your bottom line.

The first step in automating is to weigh things accurately and quickly. Smart Weigh's multihead weighers provide accurate portioning while keeping speeds that manual systems can't match. Each weigher has touchscreen controls and can store recipes so that you may quickly switch between products. There are tiny 10-head units for small businesses and big 24-head systems for big production lines.

Plan Your Layout to Maximize Space

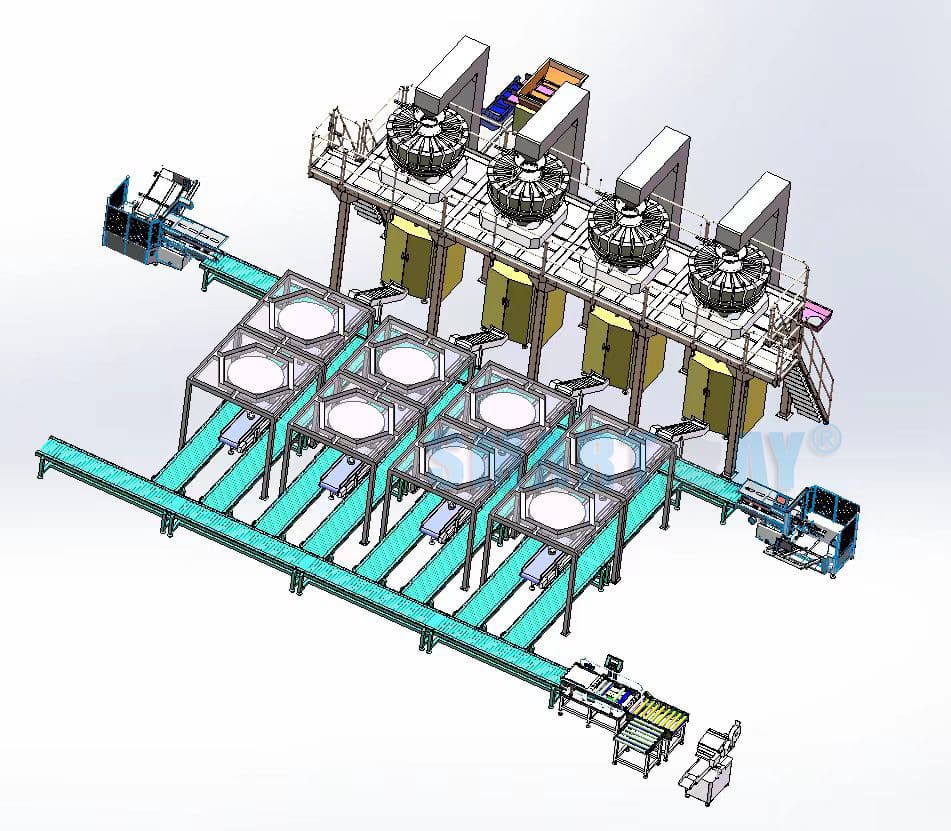

Smart Weigh's edge over the competition is that it can integrate all of its packing lines. Our multihead weighers work perfectly with VFFS baggers, making it easy for products to go from weighing to sealed containers. This integration gets rid of transfer points that can damage or contaminate products, and Smart Weigh's proprietary software makes sure that the timing between the weigher's discharge and the bagger's operation is as efficient as possible.

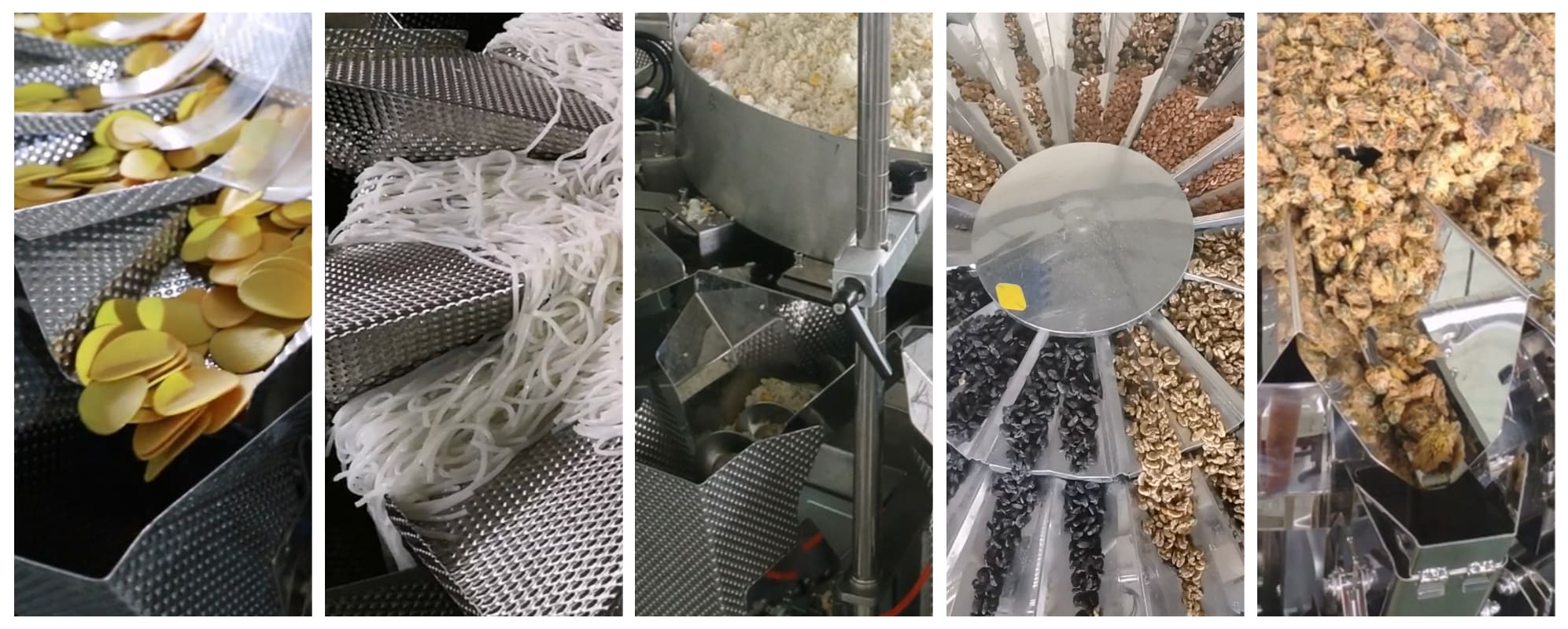

Smart Weigh has the right tools for every job because different products need to be handled in different ways. Anti-stick weigher hoppers and careful handling that keeps accumulation to a minimum are good for sticky materials. Low-drop heights and cushioned discharge systems keep fragile things safe. High-capacity load cells and strengthened constructions can handle heavy materials. Mixed product lines use quick-change parts to alter recipes quickly.

Smart Weigh's small machine designs and raised platform solutions make the most of vertical space while still making it easy for workers and maintenance to get to. This is because factory floor space is valuable real estate. Our technical staff will help you arrange your 3D layout so that materials flow smoothly from multihead weighers to VFFS systems to checkweighers and metal detectors, all while staying within the limits of your current facility.

Smart Weigh Team Expert Support

Smart Weigh automation gives you demonstrable benefits through a number of ways. Precision weighing cuts down on overpacking by 0.5 to 2%, which saves thousands of dollars on product expenditures each year. Automated systems get rid of human mistake in portioning and sealing, and one operator may run full integrated lines that used to need several personnel. Running all the time without becoming tired and slowing down the process greatly enhances the overall throughput.

You don't need to know how to operate complicated automation. Smart Weigh's easy-to-use touchscreens let operators set up the machines, and the diagnostic systems give straightforward instructions for fixing problems. With full training programs, your team will be able to get the most out of your equipment from the start, and they will be able to get help when production demands change.

We know that each food maker has its own needs. Smart Weigh's application engineers work with your team to design systems that fit your products, space, and budget. Smart Weigh offers full support from the first consultation to the installation and starting. This guarantees that the automation will be successful without any disruptions to production.

Change the way you work now with Smart Weigh.

It doesn't have to be hard to go from manual packaging to automated efficiency. Smart Weigh has installed thousands of systems around the world, and these prove that working together is the key to success. Smart Weigh's integrated technologies help snack makers and food processors with uneven portion sizes and production delays get more value right away and in the long run.

Days without automation mean less work getting done, more people quitting, and more labor costs. Smart Weigh's modular approach may swiftly change your operations without needing a lot of money or stopping production. Our app professionals will look at your problems and come up with a solution that works for your product, space, and budget.

Don't let manual tasks get in the way of your growth. Join the thousands of food companies that know how Smart Weigh automation gives them an edge over their competitors. We have the tools and experience to help you work more efficiently, from accurate multihead weighers to full packaging lines with built-in inspection systems.

Are you ready to see how Smart Weigh works? Get in touch with our packaging automation experts right now for free advice and custom line design. To see our multihead weighers, VFFS systems, and integrated packaging solutions, go to smartweigh.com or call your local Smart Weigh office. Let's speak about how to make things better, save money, and grow the business. Talk about starting your autonomous future today.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine