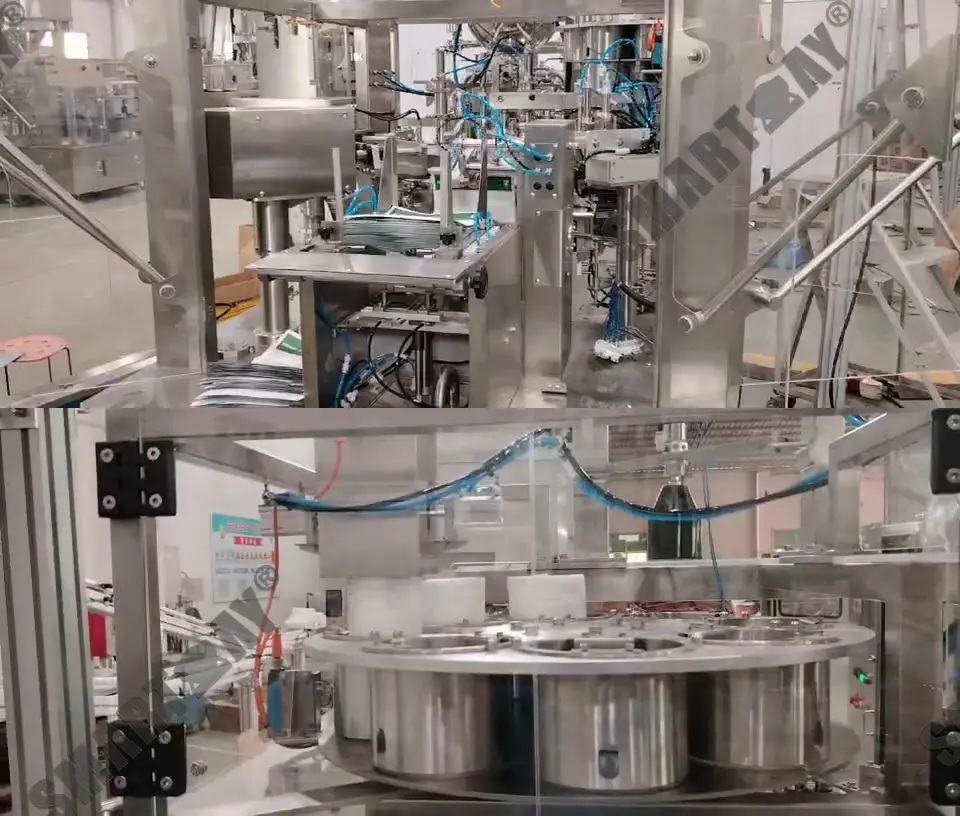

Explosion-proof Roll Isopropyl Alcohol Wipes Packaging Machine

Smart Weigh's specialized pouch packing solution for isopropyl alcohol (IPA) wipes addresses the unique challenges of packaging pre-saturated cleaning wipes for electronics manufacturing, healthcare, and industrial cleaning applications. Our integrated system ensures product integrity while maximizing packaging efficiency and minimizing contamination risks, with explosion-proof design for safe alcohol vapor handling.

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

More Choices

Smart Weigh's specialized pouch packing solution for isopropyl alcohol (IPA) wipes addresses the unique challenges of packaging pre-saturated cleaning wipes for electronics manufacturing, healthcare, and industrial cleaning applications. Our integrated system ensures product integrity while maximizing packaging efficiency and minimizing contamination risks, with explosion-proof design for safe alcohol vapor handling.

Target Applications

Healthcare & Medical: Surface disinfection wipes, equipment cleaning

Industrial Cleaning: General-purpose IPA wipes for manufacturing environments

Laboratory Applications: Contamination-free cleaning solutions

Key Technical Challenges Addressed

1. Explosion Prevention & Vapor Management

Challenge: IPA vapors create explosion hazards in packaging environments

Solution: ATEX-certified explosion-proof electrical components and vapor extraction systems

Benefit: Safe operation in hazardous alcohol vapor environments

2. Moisture Retention & Barrier Protection

Challenge: IPA evaporates quickly, requiring superior barrier films

Solution: Advanced sealing technology with multi-layer laminated films

Benefit: Extended shelf life and consistent wipe saturation

3. Contamination Prevention

Challenge: Electronics-grade IPA requires ultra-clean packaging environment

Solution: Clean room compatible design with HEPA filtration integration

Benefit: Maintains ultra-pure IPA quality standards

4. Gentle Product Handling

Challenge: Pre-saturated wipes can be damaged during packaging

Solution: Low-impact feeding systems with adjustable pressure controls

Benefit: Prevents tearing, maintains wipe integrity

Specification

| Speed | 10-20 pouches/min |

| Pouch Size | Bag Width: 80-200mm Bag Length: 160-300mm |

| Pouch Material | PE/PA, PE/PET, Aluminum laminated films |

| Film Thickness | 12-25 microns (depending on barrier requirements) |

Smart Weigh Integrated Packaging Line Components

Explosion-Proof Conveyor System

ATEX-Certified Transport: Intrinsically safe conveyor belts with anti-static properties

Vapor-Safe Operation: Non-sparking materials and grounding systems prevent ignition

Gentle Product Handling: Variable speed control to prevent wipe damage during transport

Clean Room Compatible: Smooth surfaces for easy sanitization and contamination prevention

Roll Isopropyl Alcohol Wipes Filling Machine

Explosion-Proof Design: ATEX Zone 1/2 certified for safe alcohol vapor environments

Precision IPA Application: Controlled saturation systems ensure consistent wipe moisture content

Vapor Management: Integrated extraction systems remove alcohol vapors during filling process

Roll Processing Capability: Handles continuous wipe rolls with automatic cutting and separation

Contamination Control: Enclosed filling chamber maintains product purity

Explosion-Safe Pouch Packing Machine

ATEX-Certified Components: Intrinsically safe electrical systems and explosion-proof motors

Advanced Vapor Extraction: Active removal of alcohol vapors during sealing process

Temperature-Controlled Sealing: Precise heat control prevents alcohol vapor ignition

Enhanced Barrier Sealing: Optimized for moisture-barrier films to retain IPA content

Real-Time Safety Monitoring: Gas detection systems with automatic shutdown capabilities

Variable Bag Formats: Accommodates single-serve to multi-count pouch configurations

Production Speed: Up to 30 explosion-safe packages per minute

Conclusion

Smart Weigh's explosion-proof isopropyl alcohol wipes packaging solution combines specialized knowledge of IPA handling requirements with proven safety technology and packaging expertise. Our ATEX-certified integrated approach ensures product quality, regulatory compliance, operator safety, and operational efficiency while providing measurable ROI for manufacturers in electronics, healthcare, and industrial cleaning markets.

The system's explosion-proof design eliminates the inherent safety risks associated with alcohol vapor packaging, while the modular construction allows for future expansion and adaptation as product requirements evolve. This makes it a strategic investment for companies looking to safely automate their alcohol wipes packaging operations while maintaining the highest quality and safety standards in hazardous manufacturing environments.

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Quick Link

Packing Machine