Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

Fully Automatic Tuna Tin Can Sealing Packing Machine For Food PET Tin Can Sealing Seamer Machine

Tin can sealing machines, enable to get complete tin cans packing solutions from Smart Weigh!

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

More Choices

Main parameters: | |||

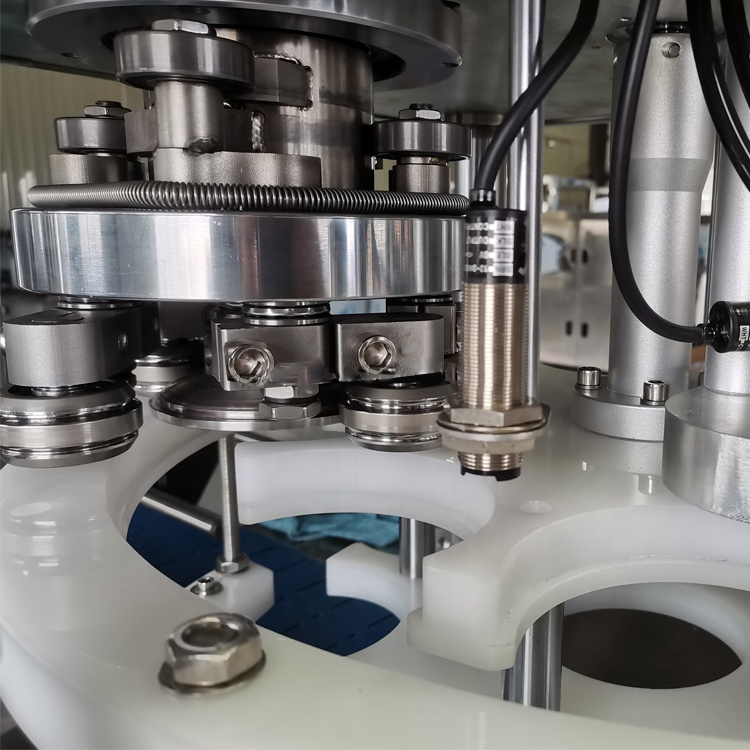

Number of sealing head | 1 | ||

Number of seaming rollers | 4 (2 first operation, 2 second operation) | ||

Sealing speed | 33 cans/ min (Not adjustable) | ||

Sealing height | 25-220mm | ||

Sealing can diameter | 35-130mm | ||

Working temperature | 0-45℃ | ||

Working humidity | 35-85% | ||

Working power supply | Single-phase AC220V S0/60Hz | ||

Total power | 1700W | ||

Weight | 330KG (about) | ||

Dimensions | L 1850 W 8404H 1650mm | ||

※ Features

Features: | ||||

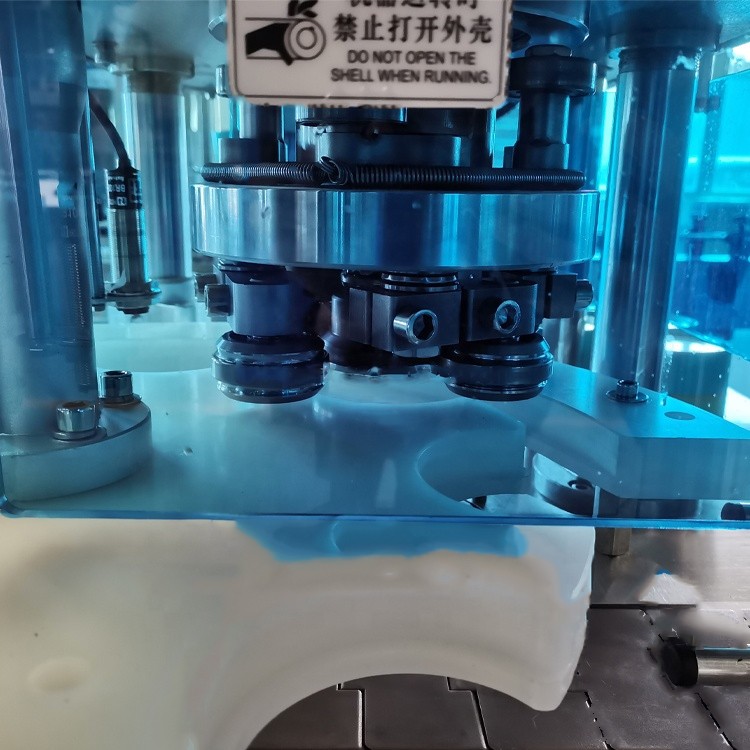

1. | Whole machine servo control makes the equipment run safer, more stable and smarter. The turntable only runs when there is a can, speed can be adjusted separately: when there is can stuck, the turntable will automatically stop. Ater one button reset, the error can be released and machine restart to run: When there is a foreign object stuck in the turntable, it will automatically stop running to prevent artificial Equipment damage and safety accidents caused by incorre coperation of the equipment. | |||

2. | A total of a seaming rollers are completed at the same time to ensure high sealing performance | |||

3. | The can body does not rotate during the sealing process, which is safer and is especially,suitable for fragile and liquld products. | |||

4. | The sealing speed is fixed at 33 cans per minute, production is automated, which improvesproduction efficiency and saves labor costs. | |||

※ Features

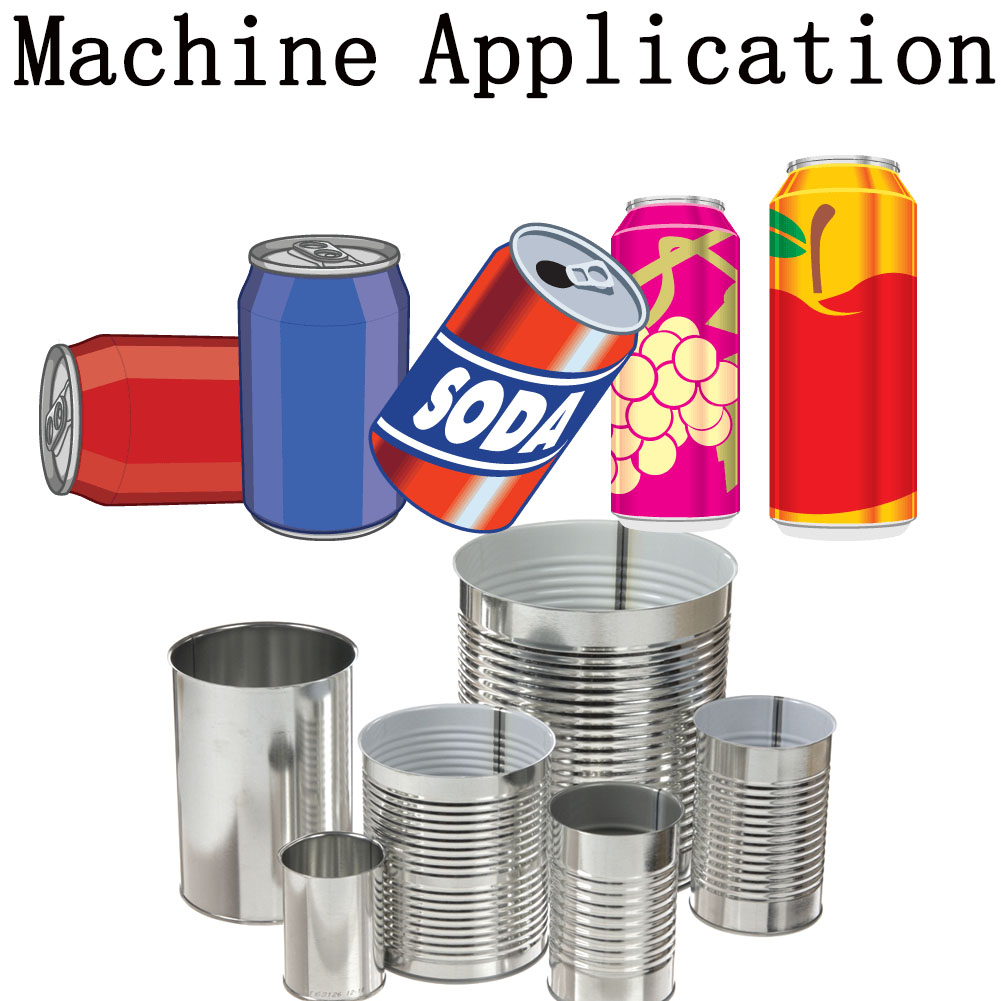

Appliacation

Applicable to tin cans, aluminum cans, plastic cans and composite paper can, it is the idea packaging equipment for food, beverage, Chinese medicine drinks, chemical industry etc.

※ Complete Solutions

The tin sealing machines can equip with other packaging machines to be a complete solutions for tin cans, the whole line machine list: infeed conveyor, multihead weigher with tin can filler, empty tin cans feeder, tin sterilization(optional), can sealing machine, capping machine(optional), labeling machine and finished can collector.

The filling machine system (multihead weigher with tin can rotary filling machines) ensure the accurate and efficient performance for solid products(tuna, nuts, dried fruits), tea powder, milk powder and other industries products.

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425