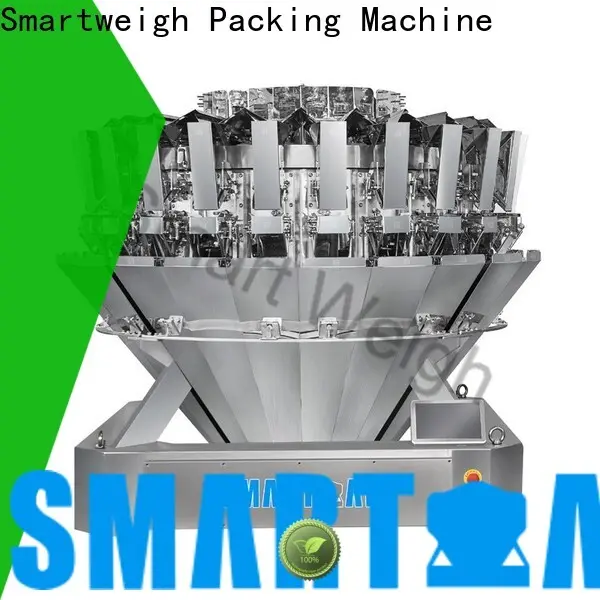

high-quality weight machine factory for food labeling

1. The design of Smartweigh Pack mainly includes the following processes: preliminary 3D solid modeling, finite element analysis of parts and assemblies, panel layouts, PLC programming according to IEC 61131-3 standards. Smart Weigh vacuum packaging machine is set to dominate the market

2. Using this product, One can easily accomplish many risky and heavy-duty tasks. This also helps to alleviate the pressure and labor of the workers. The materials of Smart Weigh packing machine comply with FDA regulations

3. This product features good water repellency. Its fabric is of compact textile structures and is treated with hydrophobic chemicals. The products after packing by Smart Weigh packing machine can be kept fresh for longer time

Model | SW-M324 |

Weighing Range | 1-200 grams |

Max. Speed | 50 bags/min (For mixing 4 or 6 products) |

Accuracy | + 0.1-1.5 grams |

Weigh Bucket | 1.0L |

Control Penal | 10" Touch Screen |

Power Supply | 220V/50HZ or 60HZ; 15A; 2500W |

Driving System | Stepper Motor |

Packing Dimension | 2630L*1700W*1815H mm |

Gross Weight | 1200 kg |

※ Features

◇ Mixing 4 or 6 kinds of product into one bag with high speed (Up to 50bpm) and precision

◆ 3 weighing mode for selection: Mixture, twin & high speed weighing with one bagger;

◇ Discharge angle design into vertically to connect with twin bagger, less collision & higher speed;

◆ Select and check different program on running menu without password, user-friendly;

◇ One touch screen on twin weigher, easy operation;

◆ Central load cell for ancillary feed system, suitable for different product;

◇ All food contact parts can be took out for cleaning without tool;

◆ Check weigher signal feedback to auto adjust weighing in better accuracy;

◇ PC monitor for all weigher working condition by lane, easy for production management;

◇ Optional CAN bus protocol for higher speed and stable performance;

※ Application

It is mainly apply in automatic weighing various granular products in food or non-food industries, such as potato chips, nuts, frozen food, vegetable, sea food, nail, etc.

※ Function

※ Product Certificate

Company Features

1. With the development of advanced technology, Smartweigh Pack not only improves the technical strength, but also meets the needs of customers.

2. Clients First is always the principle we adhere to. We regard the unhappy customers are an invaluable resource that can provide an honest assessment of our products, service and business processes. We will act proactively to clients' feedback to continually improve our business.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425