Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

How Much You Will Save In A Year? (Semi Automatic VS Full Manual )

Semi automatic weighing and packing line VS Full manual weighing and packing

One food factory manufacture candy, biscuits, seeds etc, one year’s output required is 1800tons(250g/bag, one day’s output is 6 tons), whether need to purchase one set of semi-automatic weighing and packing line to replace present’s full manual weighing and packing, let us analysis:

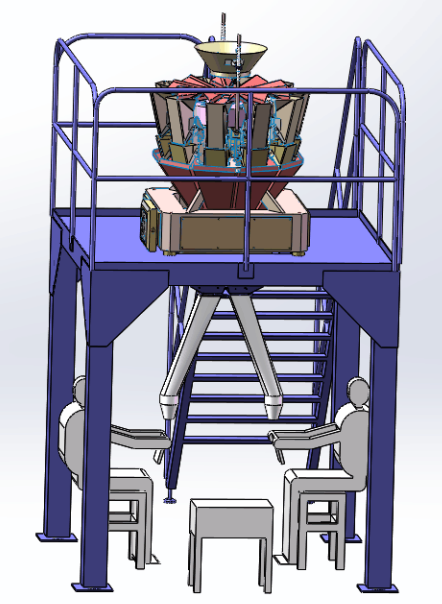

Project 1: Semi-automatic weighing and packing line

1.Budget: Multihead weigher+Platform+band sealer=$10000-12000

2.Output: 50bags/minutes X 60minutes X 8hours x 300days/yearX250g=1800tons/year

3.Accuracy: within+-1g

4.The number of workers: 5 workers/day

Project 2: Full manual weighing and packing

(table weigher for manual weighing, band sealer for manual sealing the bag.)

1.Budget: table weigher+band sealer=$3000-$5000

2.Output and number of worker: Manual feeding, weighing, filling, sealing need 4-5 worker, speed is about 10 bags per minute, one day’t output required is 6 tons, need about 20-25 workers.

3.Accuracy: within+-2g

Comprehensive evaluation:

1.Budget: Project 2 is cheaper compared with Project1($7000’s difference.)

2.Accuracy:Project 1 save product 7-10 tons per year compared with project 2

3.Worker: Project 1 save 15-20 workers per year, if one workers’ salary is $6000 per year, for project 1, which can save$90000-$120000 per year.

Conclusion: Semi automatic packing line is better than full manual weighing and packing line

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425