Quality Fresh Vegetable Fruit Cherry Tomato Packaging Machine for Sale Manufacturer | Smart Weigh

Fresh Vegetable Fruit Cherry Tomato Packaging Machine for Sale compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.Smart Weigh summarizes the defects of past products, and continuously improves them. The specifications of Fresh Vegetable Fruit Cherry Tomato Packaging Machine for Sale can be customized according to your needs.

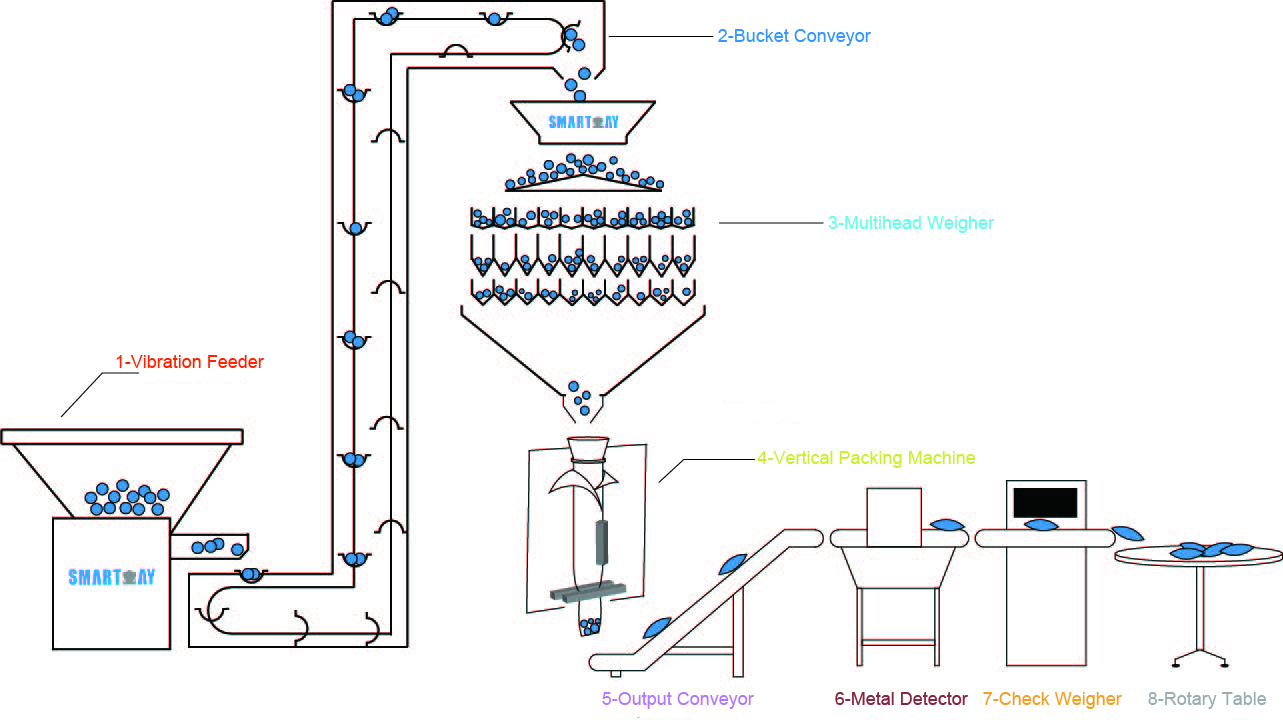

Vertical packaging system for fresh vegetables and fruits.

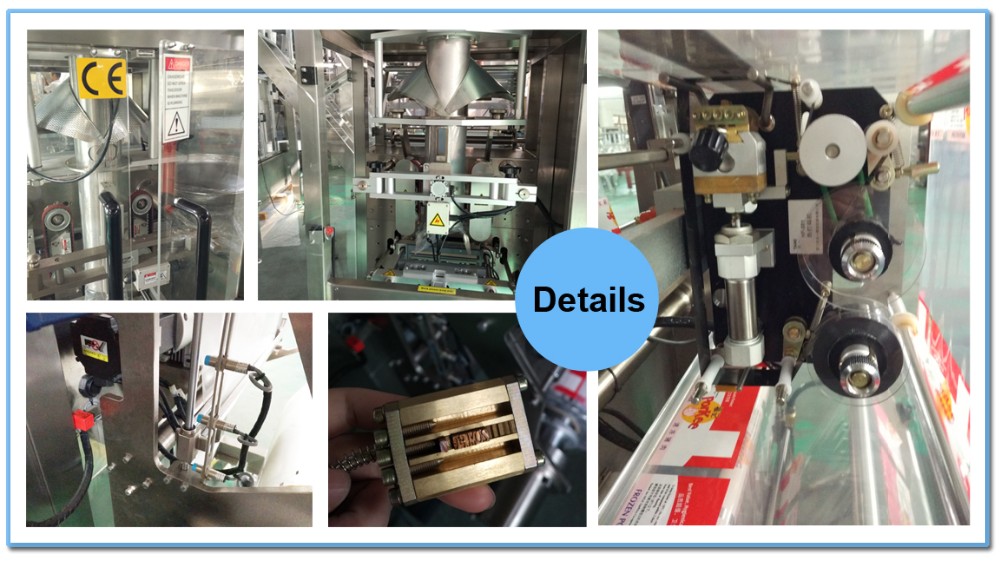

The multi-head weigher is IP65 waterproof and can be directly cleaned, and the parts in contact with food can be manually disassembled without tools.

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

More Choices

About Smart Weigh

Product Introduction

Product Information

Company Advantages

Frequently Asked Questions about tray filling and packing line

Are you looking to maximize efficiency in your tomato packing process? Look no further than our cherry tomato packing machine! We are offering 2 types of packaging machine for cherry tomatoes, they are clamshell tray denesting machine and vertical form fill seal machine with multihead weighers.

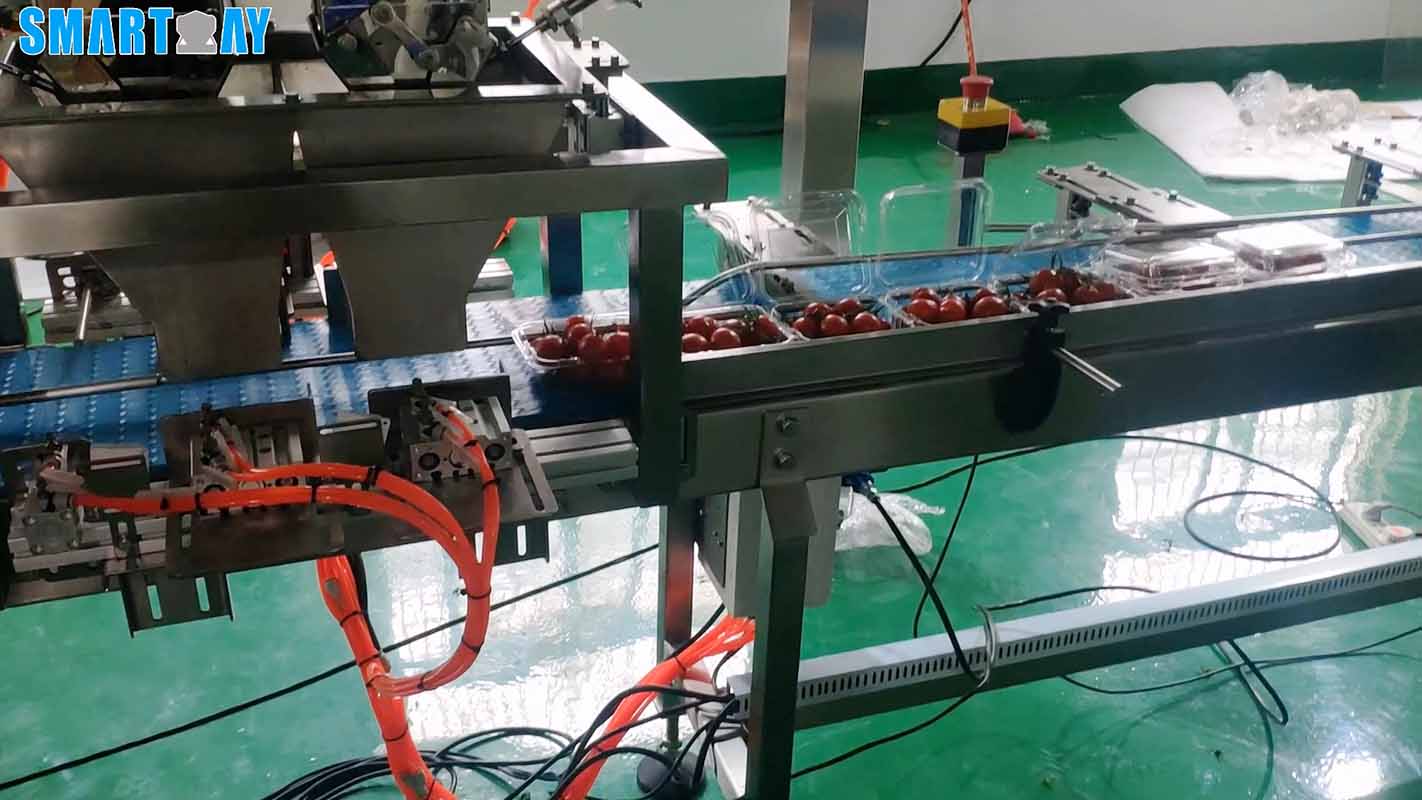

The auto packing process of clamshell cherry tomato packing machine is:

1. Incline conveyor delivers cherry tomatoes to multihead weigher

2. Multihead weigher auto weigh the cherry tomato as preset weight

3. At the same time tray denesting machine picks & places empty trays, the relevant conveyor send empty trays to filling position

4. Multi head scale auto fill tomatoes into trays

5. Close the clamshell, print the actual weight on label and stick on the top of tray.

And Smart Weigh offers another type weigher for berries, it is much soft weigher compared with the multihead weigher here. You could know more about it if you are interested.

² IP65 waterproof

² PC monitor production data

² Modular driving system stable & convenient for service

² 4 base frame keep the machine running stable & high precision

² Hopper material: dimple( sticky product) and plain option( free-flowing product)

² Electronic boards exchangeable between different model

² Load cell or photosensor checking are available for different products

Model | SW-M10 | SW-M12 | SW-M14 | SW-M16 | SW-M20 | SW-M24 |

Range(g) | 1-1000 | 10-1500 | 10-2000 | Single:10-1600 Twin:10-1000×2 | Single:10-2000 Twin:10-1000×2 | Single:3-500 Twin:3-500×2 |

Speed(bags/min) | 65 | 100 | 120 | Single: 120 Twin: 65×2 | Single: 120 Twin: 65×2 | Single: 120 Twin: 100×2 |

Mixture weighing | × | × | × | √ | √ | √ |

Accuracy(g) | ±0.1-1.5 | ±0.1-1.5 | ±0.1-1.5 | ±0.1-1.0 | ±0.1-1.0 | ±0.1-1.0 |

Touch Screen | 7” or 9.7” Touch Screen option, multi-languages option | |||||

Voltage | 220V/50HZ or 60HZ; single phase | |||||

Drive System | Stepper Motor (Modular Driving) | |||||

The above information is for your reference, actual speed is subject to your products’ features.

² Film auto centering while running

² Airlock film easy for loading new film

² Free production and EXP date printer

² Customize function & design can be offered

² Strong frame ensure running stable every day

² Lock door alarm and stop running ensure safety operation

Model | SW-P320 | SW-P420 | SW-P520 | SWP620 | SW-720 |

Bag length | 60-200 mm | 60-300 mm | 80-350 mm | 80-400 mm | 80-450 mm |

Bag width | 50-150 mm | 60-200 mm | 80-250 mm | 100-300 mm | 140-350 mm |

Max film width | 320 mm | 420 mm | 520 mm | 620 mm | 720 mm |

Bag style | Pillow bag, pillow gusset bag and standing up gusset bag | ||||

Speed | 5-55 bags/min | 5-55 bags/min | 5-55 bags/min | 5-50 bags/min | 5-45 bags/min |

Film thickness | 0.04-0.09 mm | 0.04-0.09 mm | 0.04-0.09 mm | 0.04-0.09 mm | 0.06-0.12 mm |

Air consumption | 0.65 mpa | 0.65 mpa | 0.65 mpa | 0.8 mpa | 10.5 mpa |

Voltage | 220V/50HZ or 60HZ | ||||

The above information is for your reference, actual speed is subject to your target weight.

Model | SW-PL1 |

Weighing Range | 10-5000 grams |

Bag Size | 120-400mm(L) ; 120-400mm(W) |

Bag Style | Pillow Bag; Gusset Bag; Four side seal |

Bag Material | Laminated film; Mono PE film |

Film Thickness | 0.04-0.09mm |

Speed | 20-100 bags/min |

Accuracy | + 0.1-1.5 grams |

Weigh Bucket | 1.6L or 2.5L |

Control Penal | 7" or 10.4" Touch Screen |

Air Consumption | 0.8Mps 0.4m3/min |

Power Supply | 220V/50HZ or 60HZ; 18A; 3500W |

Driving System | Stepper Motor for scale; Servo Motor for bagging |

Accessories

SW-B1 Z type bucket conveyor

SW-B1 Z type bucket conveyor| Model | SW-B1 |

Convey height | 1800-4500 mm |

Bucket volume | 1.8L or 4.0L |

Carrying speed | 40-75 buckets/min |

Bucket material | White PP (dimple surface) |

Voltage | 220V50HZ or 60HZ, single phase |

Whole frame made by SUS304 stainless steel, more stable compare with chain conveyor.

SW-B2 Incline Elevator

SW-B2 Incline ElevatorModel | SW-B2 |

Convey height | 1800-4500 mm |

Belt width | 220-400mm |

Carrying speed | 40-75 cell/min |

Bucket material | White PP (food grade) |

Voltage | 220V50HZ or 60HZ, single phase |

Can be washed down by water.

Widely used in salad, vegetable and fruit.

SW-B1 Compact working platform

Stable and safe with guardrail and ladder

Material: SUS304 or carbon steel

Standard size: 1.9(L) x 1.9(W) x 1.8(H) m

Customized size is acceptable.

SW-B4 Output conveyor

With converter, speed adjustable

Material: SUS304 or carbon steel

Height 1.2-1.5m, belt width: 400 mm

SW-B5 Rotary collect table

Two choices

Material: SUS304

Height: 730+50mm.

Diameter. 1000mm

Smart Weigh Packaging Machinery is dedicated in completed weighing and packaging solution for the foods packing industry. We are an integrated manufacturer of R&D, manufacturing, marketing and providing after-sale service. We are focusing on auto weighing and packing machine for snack food, agricultural products, fresh produce, frozen food, ready food, hardware plastic and etc.

How can we meet your requirements well?

We will recommend the suitable model of machine and make the unique design based on your project details and requirements.

How to pay?

T/T by bank account directly

L/C at sight

How can you check our machine quality?

We will send the photos and videos of the machine to you to check their running situation before delivery. What' s more, welcome to come to our factory to check the machine by you own.

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Quick Link

Packing Machine