Smart Weigh Industry 4.0 Snack Weighing Packaging Line

What Industry 4.0 Means for Food Manufacturers

The fourth industrial revolution is changing the way snacks are made from reactive, separate processes into proactive, linked ecosystems. For food makers, Industry 4.0 means a big change from "running blind" to making decisions based on data that improve every part of the production process.

In today's competitive snack manufacturing industry, using Industry 4.0 technology is necessary to keep operations running smoothly and stay competitive in the market. Smart Weigh's whole range of weighing and packaging solutions is a big step ahead in automated manufacturing technology. They make equipment more efficient, accurate, and overall effective.

Why Snack Foods Need Better Packing Machines

Traditional weighing methods have trouble with the special problems that the snack food business faces. Not only is advanced technology good, it's necessary for competitive manufacturing.

Product Variety Problems (Chips, Nuts, Candies, and Crackers)

Different types of snacks need different ways of weighing and packing, and many companies make more than one type of food on the same line. You have to be careful with potato chips so they don't break, and you have to be exact with nuts since they are so expensive. In warm settings, candies can stick to surfaces, and crackers come in different sizes and shapes, which can affect how well the weigher works.

Smart Weigh's innovative technologies keep track of product-specific profiles that immediately modify all settings when the product changes. The system keeps track of the fact that kettle chips need a gentler vibration, a slower discharge rate, and different combination algorithms than peanuts. Product recognition technology can even find things on its own, which gets rid of mistakes that people make while choosing products that hurt quality.

The problem also affects seasonal items and limited editions. A company might only make pumpkin spice nuts for three months out of the year. Operators of traditional systems have to relearn the best settings every season, which can waste a lot of time during setup. Advanced systems keep historical data and can quickly recall the best settings from past production runs.

Requirements for High-Speed Production

Modern snack production needs speeds that are too fast for standard packing machine to handle. In snack applications, a typical multihead weigher vffs could need to run 60-80 packs each minute while keeping the same level of accuracy.

Smart Weigh's snack packing line can work quickly, speed up 600 packs/min, because the machine has advanced controls, efficient algorithms, and precise manufacture. The systems stay accurate even at their highest speeds because to smart combination selection and the ability to make adjustments in real time. The advanced vibration dampening and structural design stop the accuracy loss that happens with earlier systems when the speed changes.

Smart Weigh's Industry 4.0 Packing Line Solutions

The modern snack food sector needs packaging solutions that work really well and can be used in a variety of ways. Smart Weigh offers custom Industry 4.0 solutions that boost efficiency, quality, and profits, whether you're working in a small locati0n or running a huge production facility.

Today's snack makers have to deal with very different business realities. Facilities with limited space need to be able to produce a lot of goods in a small area, whereas large-scale producers need to be able to handle a lot of throughput across several product lines at the same time.

Smart Weigh has two specific solutions to deal with these unique problems: our small 20-head dual VFFS system for high-volume manufacturing that doesn't take up much space, and our full multi-line systems for large operations that need the most capacity and flexibility.

Both options use Smart Weigh's Industry 4.0 technology to provide smart automation, predictive maintenance, and real-time optimization. This makes sure that your facility runs at its best, no matter how big or small it is or how much it needs to produce.

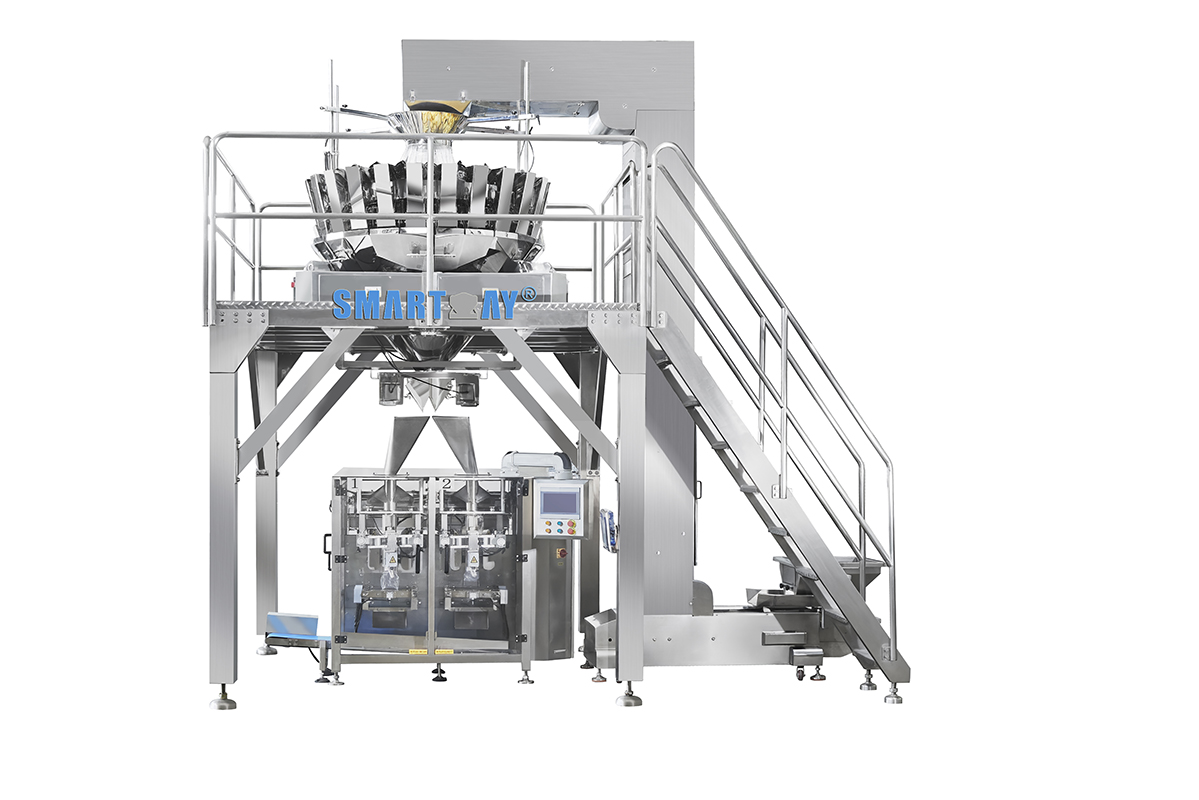

A. Smart Weigh 20-Head Multihead Weigher with Dual VFFS System: Space-Efficient High-Volume Solution

For manufacturers facing space constraints but demanding maximum production output, Smart Weigh's 20-head dual VFFS system delivers exceptional throughput in a compact footprint.

Compact Design Specifications

Space-Optimized Configuration: Footprint: 2000mm (L) × 2000 mm (W) × 4500mm (H)

● Vertical design minimizes floor space requirements

● Integrated platform reduces installation complexity

● Modular construction allows flexible positioning

High-Volume Performance: Combined output: 120 bags per minute

●Dual VFFS operation doubles capacity without doubling space

●20 weighing heads provide optimal combination accuracy

●Continuous operation capability for 24/7 production

●Smart Features for Space-Limited Facilities

●Vertical Integration Design

Dual VFFS Space Advantages

Two VFFS machines operating from one weigher provide:

● 50% space savings: Compared to two separate weigher-VFFS lines

● Redundant operation: Production continues if one machine needs maintenance

● Flexible sizing: Different bag sizes simultaneously on each machine

● Simplified utilities: Single power and air supply connection

Advanced Automation for Limited Staffing

Space-limited facilities often have staffing constraints. The system includes:

● Automatic product changeover: Reduces manual intervention requirements

● Self-monitoring systems: Predictive maintenance minimizes unexpected stops

● Remote diagnostics: Technical support without on-site visits

● Intuitive HMI: Single operator can manage entire system

Performance Specifications

| Model | 24 head dual vffs machine |

| Weighing range | 10-800 grams x 2 |

| Accuracy | ±1.5g for most snack products |

| Speed | 65-75 packs per minute x 2 |

| Bag Style | Pillow bag |

| Bag Size | Width 60-200mm,length 50-300 mm |

| Control System | VFFS: AB controls, multihead weigher: modular control |

| Voltage | 220V,50/60HZ,single phase |

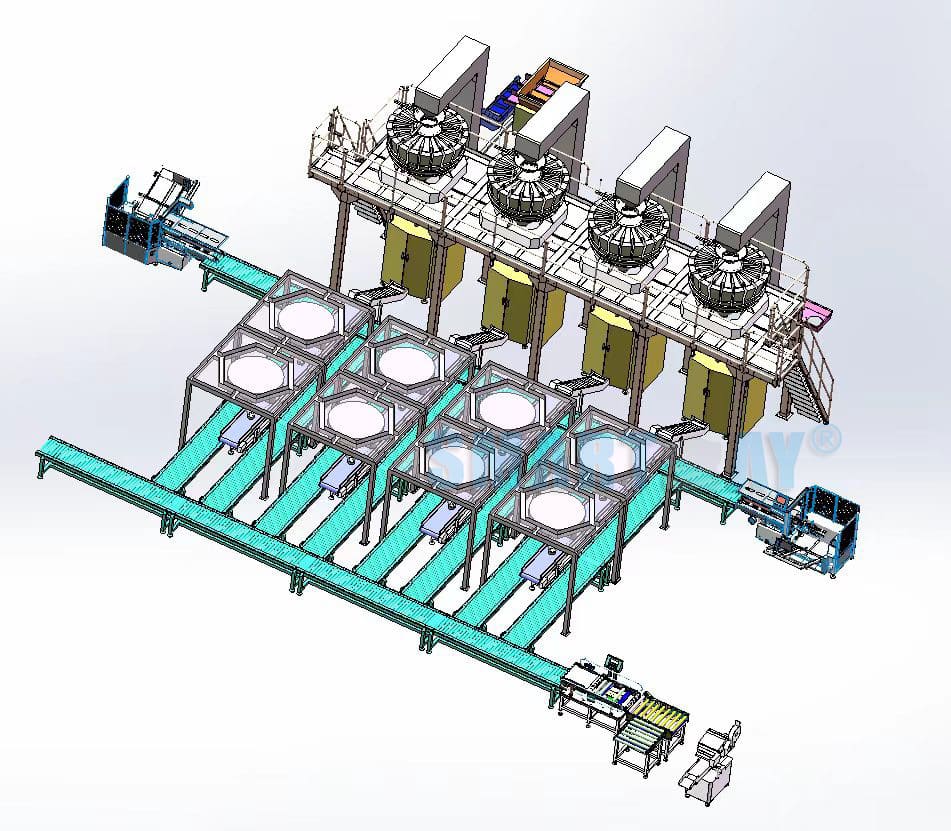

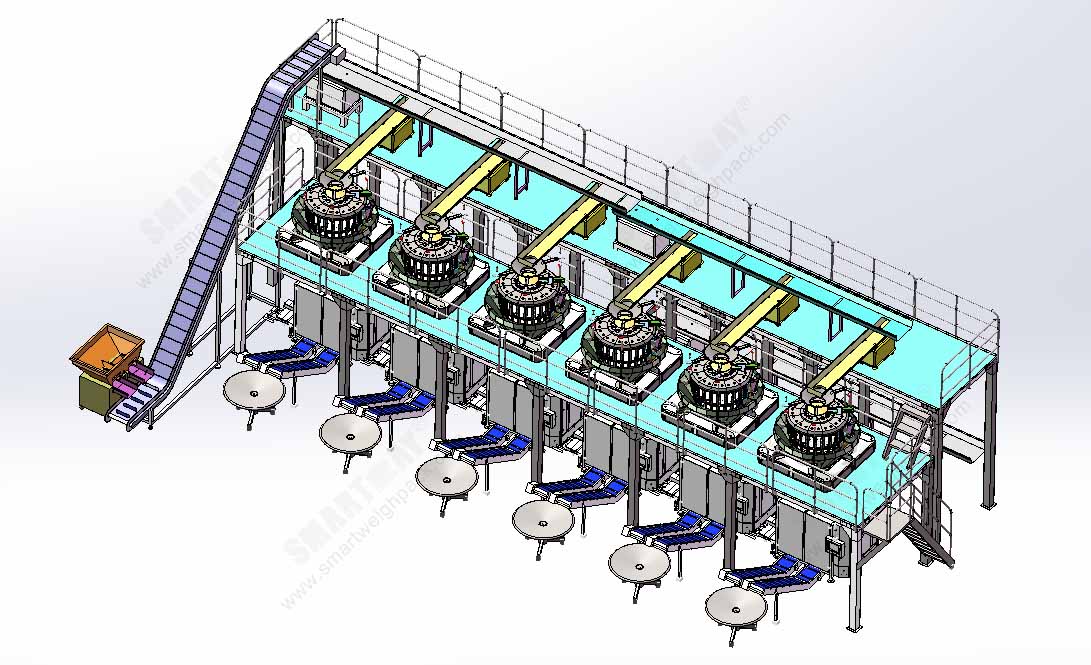

B. Smart Weigh Snacks Multihead Weigher VFFS Packing Line: Large-Scale Production System

For major manufacturers with extensive facilities and massive production requirements, Smart Weigh offers comprehensive multi-line systems featuring multiple high-speed weigher-VFFS combinations.

Scalable System Architecture

Multi-Line Configuration:

● 3-8 independent weigher-VFFS stations

● Each station: 14-20 head multihead weigher with high speed VFFS

● Total system output: 80-100 bags per minute for each set

● Modular design allows incremental expansion

Large Facility Integration:

● System length: 5-20 meters depending on configuration

● Centralized control room for all production lines

● Integrated conveyor systems for product distribution

● Comprehensive quality control throughout entire system

● Centralized Production Control

Snack Packing Machine each Set Capabilities:

| Multihead Weighing | 14-20 head multihead weigher configurations |

| Weighing range | 20g to 1000g per bag |

| Speed | 60-80 bags per minute per set |

| Bag Style | Pillow Bag |

| Bag Size | Width 60-250mm,length 50-350 mm |

| Voltage | 220V,50/60HZ,single phase |

Flexible Product Handling:

● Different products simultaneously on different lines

● Automatic product recognition and line assignment

● Cross-contamination prevention between allergen products

● Rapid changeover coordination across multiple lines

● Comprehensive Integration Systems

Optional Machines:

● Snacks seasoning and coating machine

● Waste collection and recycling systems

● Checkweigher and Metal detection systems with automatic rejection

● Automatic case packing systems

● Palletizing robots for finished goods

● Wrapping and labeling Machines

Why Choose Smart Weigh - China Packing Line Manufacturer

Thechoice to work with Smart Weigh is based on a number of important strategic benefits that make us the best choice among China's packaging equipment manufacturers: Smart Weigh has reached the same level of technology as its foreign competitors while keeping its costs low. Our equipment gives you 85–90% of the best European features at 50–60% of the cost, so you get great value without giving up important performance or reliability criteria.

Quick Customization Options: Smart Weigh is better than multinational manufacturers who focus on standardized solutions because it can meet the needs of different types of snacks. We can easily change our equipment to fit the needs of different Chinese snacks, such as rice crackers, spicy nuts, traditional sweets, and snacks that don't fit into any of the usual shapes.

Comprehensive Global Service Network: Smart Weigh operates four major service centers strategically located across continents - in the United States, Indonesia, Spain, and Dubai. This global infrastructure ensures rapid technical support and maintenance services for our international customers, providing localized expertise while maintaining consistent service quality standards worldwide.

Flexible Partnership Approach: We can work with projects of all sizes and budgets, from simple renovations to existing facilities to brand new installations. Smart Weigh works with manufacturers to make phased implementation strategies that work with their cash flow needs and operational limits.

Long-term Partnership Commitment: Smart Weigh goes beyond just providing equipment. They develop lasting connections by offering continuing performance optimization services, technology upgrade pathways, and assistance for business growth. We measure our performance by how well our customers do, which gives us incentives to grow together.

Competitive Total Cost of Ownership: Smart Weigh has lower initial investment costs than foreign options, and this advantage lasts for the whole life of the equipment. Parts costs, service fees, and upgrade charges stay competitive, which is good for the long-term economy.

Conclusion

Smart Weigh's Industry 4.0 snack weighing and packaging solutions are more than just new technology; they are a complete approach to making things better. Smart Weigh uses established mechanical engineering along with the latest automation to make things run more smoothly, enhance quality, and make more money.

Smart Weigh is the best solution for snack makers that want to embrace the future of automated packing technology because it has great performance, full service support, great financial returns, and technology that is ready for the future.

Smart Weigh's all-encompassing strategy not only meets current operational needs but also lays the groundwork for future growth and competitiveness. Smart Weigh's Industry 4.0 solutions help producers face the challenges of changing market demands for more customization, shorter lead times, and higher quality standards while still doing a fantastic job.

Call Smart Weigh immediately to set up a full evaluation of your packaging needs and find out how Industry 4.0 solutions may improve your production capabilities while giving you a great return on investment. Our team of professionals is ready to provide a unique solution that meets your needs and sets your business up for success in the future.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine