Smartweigh Pack automated packaging systems in bulk for food labeling

The product provides enough fun for children and adults, and it adds extra excitement to any events or celebrations. Smart Weigh vacuum packaging machine is set to dominate the market

brand

smartweigh

country of origin

china

material

sus304

certificate

ce

loading port

zhongshan port, china

moq

1

payment

tt, lc

Company Advantages

1. The surface treatment of Smartweigh Pack mainly includes degreasing, anodizing, sandblasting, painting, and laser engraving. It has to go through surface inspection to guarantee burr free. Smart Weigh packing machine is also widely used for non-food powders or chemical additives

2. The product provides enough fun for children and adults, and it adds extra excitement to any events or celebrations. Smart Weigh vacuum packaging machine is set to dominate the market

3. automated packaging systems is of , therefore it is worthy of popularization. All the parts of Smart Weigh packing machine which would contact the product can be sanitized

4. The product is repeatedly tested to refuse any flaws. Smart Weigh packing machine is highly reliable and consistent in operation

5. Enhanced product quality is guaranteed with systematic quality improvement activities. The compact footprint of Smart Weigh wrapping machine helps make the most out of any floorplan

![Smartweigh Pack automated packaging systems in bulk for food labeling 6]()

![Smartweigh Pack automated packaging systems in bulk for food labeling 7]()

![Smartweigh Pack automated packaging systems in bulk for food labeling 8]()

![Smartweigh Pack automated packaging systems in bulk for food labeling 9]()

![Smartweigh Pack automated packaging systems in bulk for food labeling 10]()

![Smartweigh Pack automated packaging systems in bulk for food labeling 11]()

![Smartweigh Pack automated packaging systems in bulk for food labeling 12]()

Company Features

1. We have a group of professionals. They have abundant knowledge and experience in developing, creating, and inventing new products for clients, as well as a deep understanding of market trends.

2. Leading the automated packaging systems industry has always been one of the aims of Guangdong Smart Weigh Packaging Machinery Co., Ltd. Welcome to visit our factory!

1. The surface treatment of Smartweigh Pack mainly includes degreasing, anodizing, sandblasting, painting, and laser engraving. It has to go through surface inspection to guarantee burr free. Smart Weigh packing machine is also widely used for non-food powders or chemical additives

2. The product provides enough fun for children and adults, and it adds extra excitement to any events or celebrations. Smart Weigh vacuum packaging machine is set to dominate the market

3. automated packaging systems is of , therefore it is worthy of popularization. All the parts of Smart Weigh packing machine which would contact the product can be sanitized

4. The product is repeatedly tested to refuse any flaws. Smart Weigh packing machine is highly reliable and consistent in operation

5. Enhanced product quality is guaranteed with systematic quality improvement activities. The compact footprint of Smart Weigh wrapping machine helps make the most out of any floorplan

Lettuce Leafy Vegetables Vertical Packing Machine

This is the vegetable packing machine solution for the height limit plant. lf your workshop is with a high ceiling, another solution is recommended - One conveyor: complete vertical packing machine solution.

MACHINE LIST

1. Incline conveyor

2. 5L 14 head multihead weigher

3. Supporting platform

4. Incline conveyor

5. Vertical packing machine

6. Output conveyor

7. Rotary table

SPECIFICATION

Model | SW-PL1 |

Weight (g) | 10-500 grams of vegetables |

Weighing Accuracy(g) | 0.2-1.5g |

Max. Speed | 35 bags/min |

Weigh Hopper Volume | 5L |

| Bag Style | Pillow bag |

| Bag Size | Length 180-500mm, width 160-400mm |

Control Penal | 7" Touch Screen |

Power Requirement | 220V/50/60HZ |

APPLICATION

Leafy vegetables

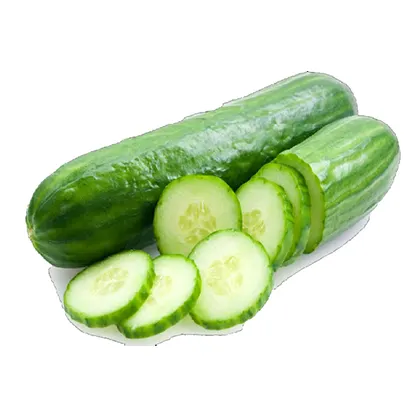

Cucumbers

Salad Pillow Bag

FEATURES

The salad packaging machine fully-automatically procedures from material feeding, weighing, filling, forming, sealing, date-printing to finished product output.

1

Incline feeding vibrator

The incline angle vibrator makes sure the vegetables flow earlier. Lower cost and efficient way compared with belt feeding vibrator.

2

Fixed SUS vegetables separate device

Firm device because it is made of SUS304, it could separate the vegetable well which is feed from the conveyor. Well and continuous feeding is good for weigher accuracy.

3

Horizontal sealing with the sponge

The sponge could eliminate the air. When the bags is with nitrogen, this design could ensure the nitrogen percent as much as possible.

Company Features

1. We have a group of professionals. They have abundant knowledge and experience in developing, creating, and inventing new products for clients, as well as a deep understanding of market trends.

2. Leading the automated packaging systems industry has always been one of the aims of Guangdong Smart Weigh Packaging Machinery Co., Ltd. Welcome to visit our factory!

{{scoreAvg}}

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Contact Us

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Contact us

Leave your inquiry, we will provide you with quality products and services!

Contact us

whatsapp

Contact customer service

Contact us

whatsapp

cancel

Customer service