Smartweigh Pack powder packing machine price supply bulk buy

| MR Series | SW-200R | SW-200RW | SW-300R | -400R |

|---|---|---|---|---|

| Capacity | up to 80bags/min | up to 80bags/min | up to 80bags/min | up to 80bags/min |

| Filling Volume | 5 – 2500g | 5 – 2500g | 10 – 2500g | 10 – 3500g |

| Total Power Consumption | 3.3kw | 3.3kw | 3.3kw | 3.3kw |

| Dimension | 1460 * 2500 * 1400mm | 1710 * 1505 * 1640mm | 2460 * 1830 * 1460mm | 2400 * 1750 * 1600mm |

| Compress Air Requirement (supply by user) | 0.6 – 0.8m³/min | 0.6 – 0.8m³/min | 0.6 – 0.8m³/min | 0.6 – 0.8m³/min |

| Bag Width | 55 – 200mm 2 – 7.9in | 55 – 200mm 2 – 7.9in | 180 – 300mm 7 – 11.8in | 280 – 400mm 11 – 15.7in |

| Bag Length | ≤ 350mm ≤ 13.8in | ≤ 350mm ≤ 13.8in | ≤ 350mm ≤ 13.8in | ≤ 650mm ≤ 25.6in |

CE 6/8 working stations automatic rotary powder premade bag packaging machine masala pouch packing sealing machine

※ Feture

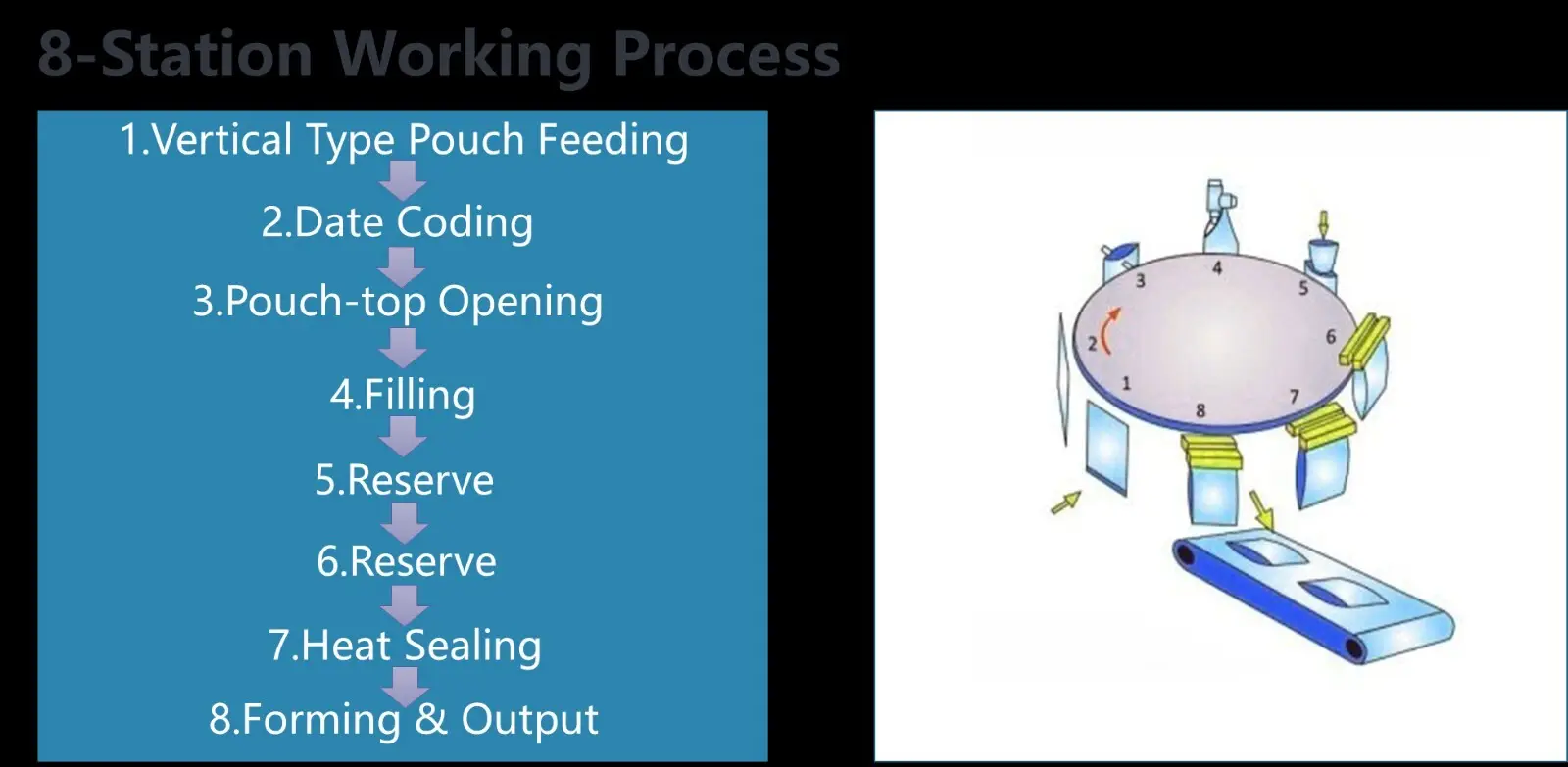

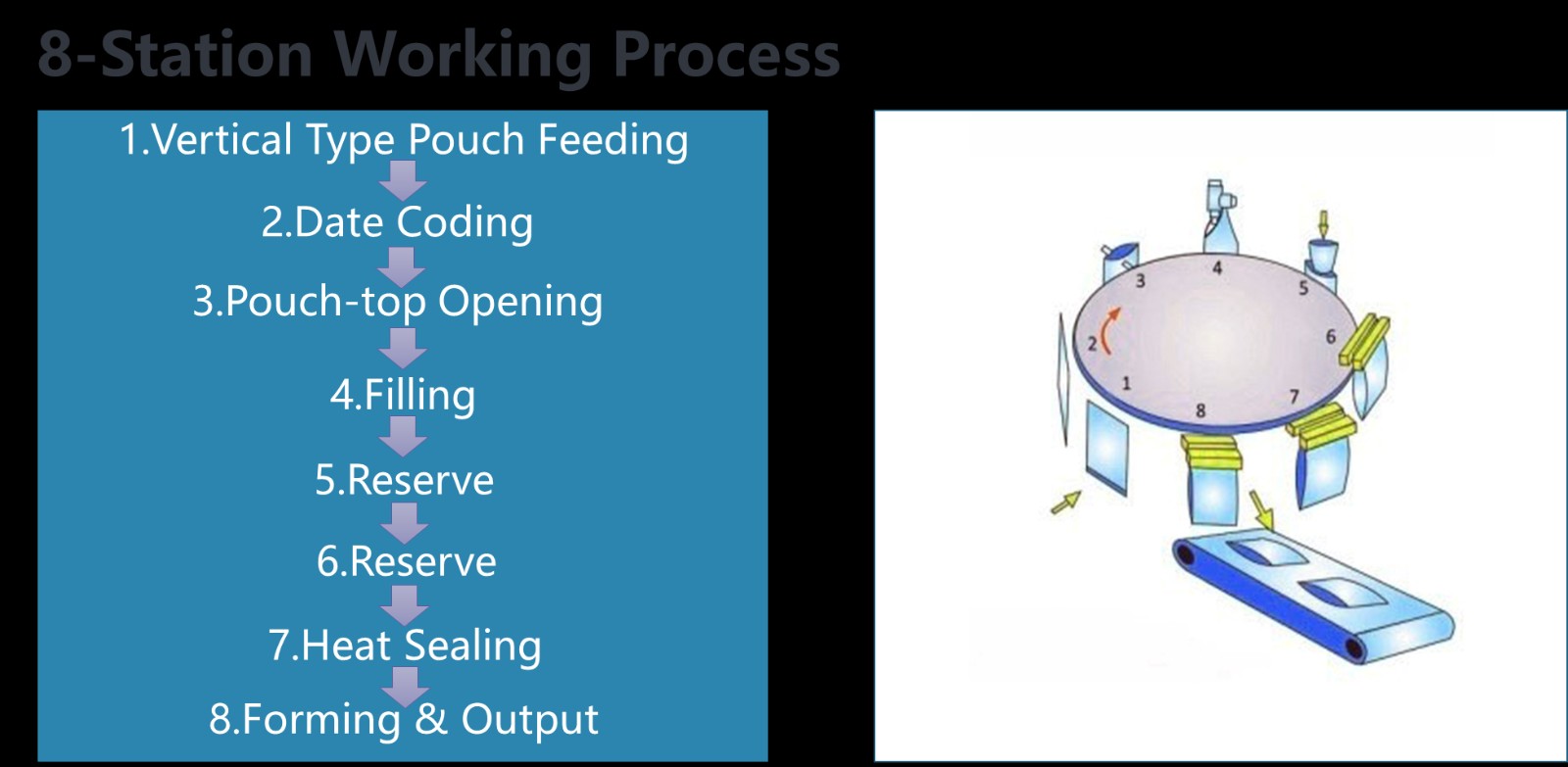

Fully automatic rotary 8 station intermittent rotary preformed bag dispensing, opening and closing.

Versatile in design, easy to link up with other down stream packaging equipment such as liquid filler, multi-heads weigher, metal detector, check weigher, case sealer etc.

Strict mechanical safety standards to ensure stable operation of machinery and increase packaging speed.

Heavy parts are used to improve the durability of machinery.

The simple design of the touch screen control system facilitates the use of operators, and is simple and easy to use.

Improve the solution, reduce the cost for you.

The production line meets the requirements of food hygiene and is convenient to clean.

Automatic control of a series of processes from loading, filling, sealing, and finished products.

Automatic lubrication system

※ Application

All kinds of powder, like milk powder, coffee, spices, additives ,washing powder,seasoning,sugar powder, coffee powder, wheat flour, detergent powder, coconut powder, etc.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425