Automatic Cereal Packaging Machine for Oats & Corn Flakes - VFFS System

Product features

The Automatic Cereal Packaging Machine for Oats & Corn Flakes integrates a high-precision multihead weigher and a vertical form-fill-seal (VFFS) system, ensuring accurate portion control and airtight packaging to preserve product quality while minimizing grain breakage. Designed by leading vffs machine manufacturers, it features modular components like metal detection, check weighing, and an output conveyor that collectively enhance food safety and streamline production efficiency with minimal labor. Constructed from durable materials and equipped with customizable speed settings, this machine adapts seamlessly to commercial cereal packing needs, providing consistent output and long-term operational stability.

Team strength

Our Automatic Cereal Packaging Machine for Oats & Corn Flakes is backed by a highly skilled and dedicated team with extensive expertise in packaging technology and food industry standards. Each member brings specialized knowledge in mechanical engineering, automation, and quality control, ensuring precise performance and reliability. This cohesive team continuously innovates to optimize the VFFS system, delivering efficient, consistent packaging that meets strict hygiene and safety regulations. Their commitment to excellence guarantees robust machine durability, minimal downtime, and seamless integration into production lines—providing exceptional value and confidence to your cereal packaging operations.

Why choose us

Our team driving the Automatic Cereal Packaging Machine for Oats & Corn Flakes is a perfect blend of engineering excellence and industry expertise. With years of experience in VFFS system design and automation, our skilled professionals ensure high precision, durability, and efficiency in every machine we deliver. Committed to innovation and customer satisfaction, our team continuously refines technology to meet evolving packaging needs. Their strong collaboration and problem-solving capabilities guarantee reliable performance and seamless integration into production lines. Backed by dedicated service and technical support, our team stands as the backbone of quality and trust, empowering your cereal packaging operations with unmatched expertise.

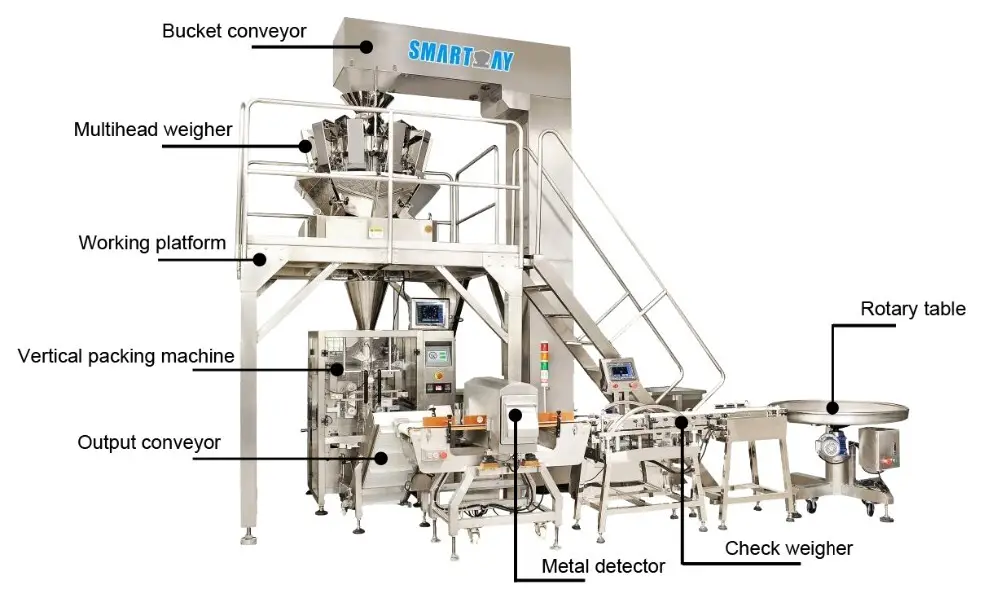

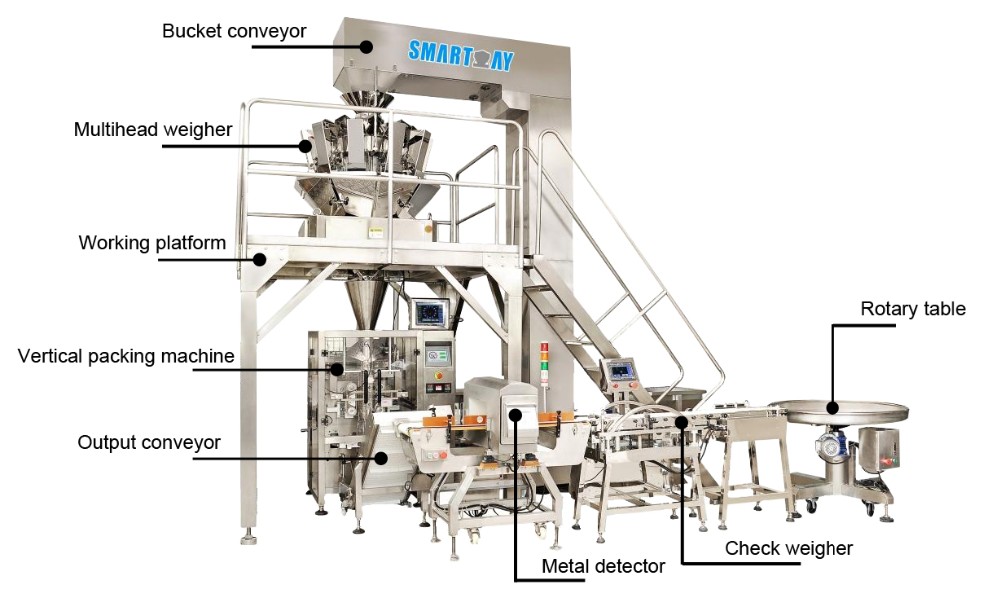

Corn Flakes Cereal Packaging Machine

About cereal packing machine list:

1. Z bucket conveyor: auto feed cereals, oats, corn flakes to multihead weigher

2. Multihead weigher: auto weigh and fill cereals, oats, corn flakes as preset weight

3. Working platform: stand for multihead weigher

4. Vertical packing machine: auto pack and make bags

5. Output conveyor: convey finished bags to next machine

6. Metal detector: detect if there is metal in bags for food safety

7. Check weigher: check weight of finished bags again, auto reject unqualified bags

8. Rotary table: collect finished bags

Corn Flakes Vertical Packaging Machines Advantages:

The cereal packaging machine is the perfect solution for commercial production lines. With its easy-to-use controls, it produces uniformly and quickly packed bags of cereals with minimal labour needed. It ensures exact portions are included in each bag while also maintaining food quality and standards by not crushing grains during the packing process. Moreover, this machine offers several speed levels allowing producers to handle different volumes and sizes of cereals as needed in their production line. Its sturdy construction also guarantees its longevity even when working continuously using heavy duty materials. By investing in this cereal packing machine your team will experience an increase in productivity and efficiency by being able to quickly pack batches of cereals without worrying about time or safety issues.

Model | SW-PL1 |

Weighing Range | 10-5000 grams |

Bag Style | Pillow bag, gusset bag |

Bag Size | Length: 120-400mm Width: 120-350 mm |

Bag Material | Laminated film, Mono PE film |

Film Thickness | 0.04-0.09 mm |

Max. Speed | 20-50 bags/min |

Accuracy | ±0.1-1.5 grams |

Weigh Bucket | 1.6L or 2.5 L |

Control Penal | 7" or 9.7 " Touch Screen |

Air Consumption | 0.8 Mps, 0.4m3/min |

Driving System | Step motor for scale, servo motor for packing machine |

Power Supply | 220V/50 Hz or 60 Hz, 18A, 3500 W |

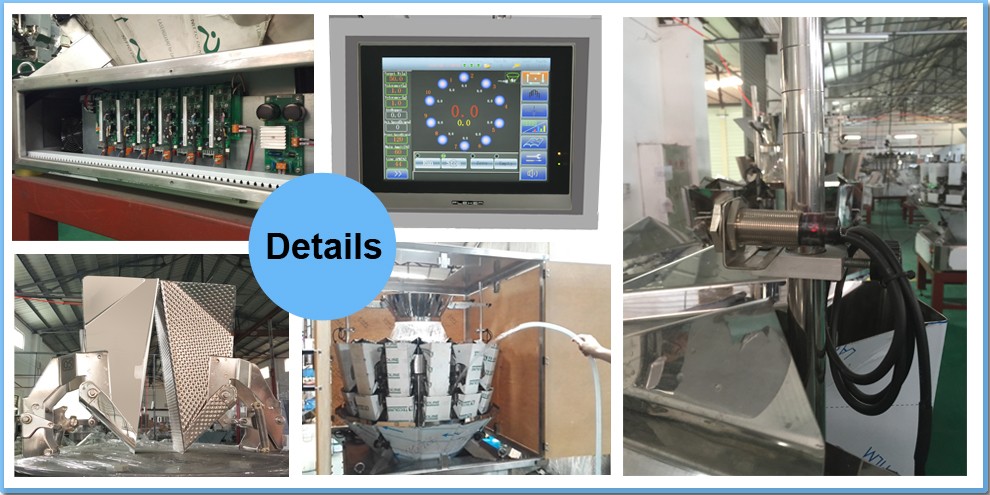

Multihead Weigher

ü IP65 waterproof

ü PC monitor production data

ü Modular driving system stable & convenient for service

ü 4 base frame keep machine running stable & high precision

ü Hopper material: dimple (sticky product) and plain option (free flowing product)

ü Electronic boards exchangeable between different models.

ü Load cell or photo sensor checking are available for different product

Option devices of multihead weigher

Dimple (sticky product) and plain (free flowing product) option |

Timing hopper- shorten discharge distant, helpful for high speed packing line |

0.5L/1.6L/2.5L/5L hopper volume is option between 10 head and 14 head weigher |

Slide 120° discharge for fragile products option |

Multi languages option |

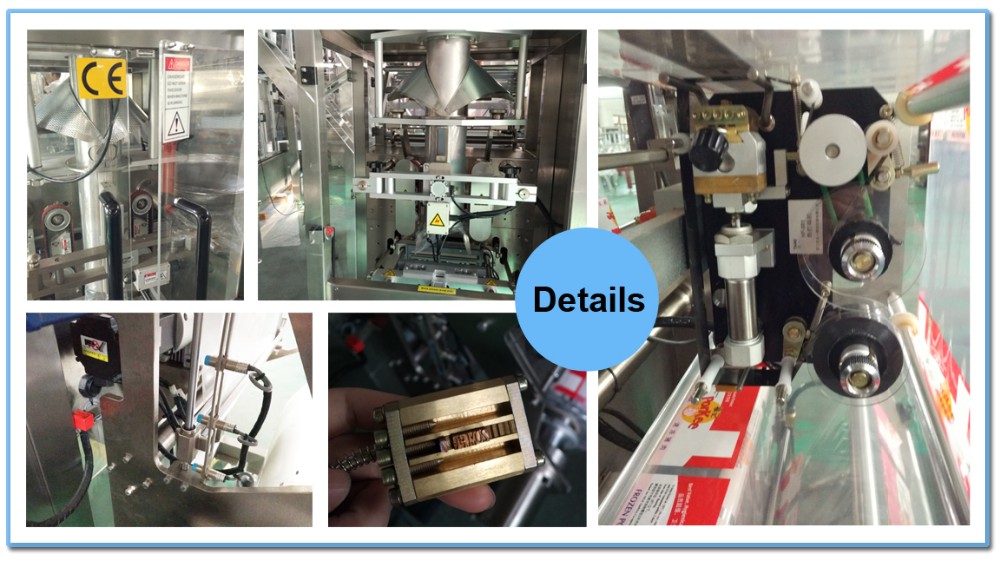

Vertical packing machine

√ Film auto centering while running

√ Air lock film easy for loading new film

√ Free production and EXP date printer

√ Customize function & design can be offered

√ Strong frame ensure running stable everyday

√ Lock door alarm and stop running ensure safety operation

Option devices of vertical packing machine

Thermal Transfer Printer can change printing letter on PC, more convenient

One bag former can make one bag width, different bag width need different bag former

PE single layer device

Encoder for clear film to get more correct pulling

Gusset device - to make a pillow gusset bag/standing up gusset bag

Turnkey Solutions Experience

Exhibition

1. How can you meet our requirements and needs well?

We will recommend the suitable model of machine and make the unique design based on your project details and requirements.

2. Are you manufacturer or trading company?

We are manufacturer; we are specializing in packing machine line for many years.

3. What about your payment?

² T/T by bank account directly

² Trade assurance service on Alibaba

² L/C at sight

4. How can we check your machine quality after we place an order?

We will send the photos and videos of the machine to you to check their running situation before delivery. What’s more, welcome to come to our factory to check the machine by you own

5. How can you ensure you will send us the machine after the balance paid?

We are a factory with business license and certificate. If that is not enough, we can make the deal through trade assurance service on Alibaba or L/C payment to guarantee your money.

6. Why we should choose you?

² Professional team 24 hours provide service for you

² 15 months warranty

² Old machine parts can be replaced no matter how long you have bought our machine

² Oversea sevice is provided.

Quick Link

Packing Machine