Custom auto bagging system China supplier Manufacturer | Smart Weigh

Guided by scientific and technological innovation, Smart Weigh always keeps outward-oriented and sticks to the positive development on the basis of technological innovation. auto bagging system We promise that we provide every customer with high-quality products including auto bagging system and comprehensive services. If you want to know more details, we are glad to tell you.Smart Weigh auto bagging system is developed with an operating principle - using the heat source and air flow system to reduce the water content of the food.

The flour starch cassava packaging machine, typically consisting of an auger filler and a premade pouch packing machine, is designed for the efficient and accurate packaging of flour.

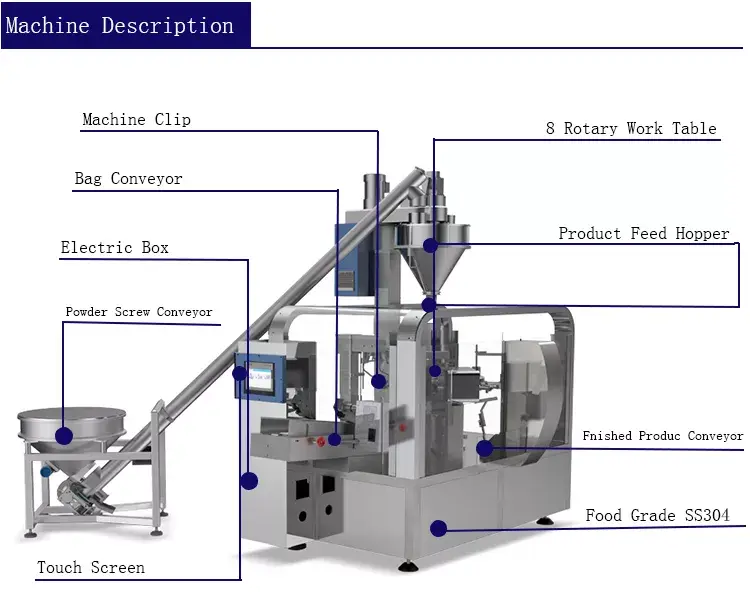

Auger Filler:

Function: Primarily used for metering and filling powder products like flour.

Mechanism: It uses a rotating auger to move the flour from the hopper into the pouches. The speed and rotation of the auger determine the amount of product dispensed.

Advantages: Provides precision in measurement, minimizes product waste, and is capable of handling various powder densities.

Premade Pouch Packing Machine:

Function: This machine is used to pack the flour into premade pouches.

Mechanism: It picks up individual premade pouches, opens them, fills them with the product dispensed from the auger filler, and then seals them.

Features: Often includes capabilities like vacuuming out air from the pouch before sealing, which prolongs the shelf-life of the product. It may also have printing options for lot numbers, expiration dates, etc.

Advantages: High efficiency in packing, versatility in handling different pouch sizes and materials, and ensuring airtight seals for product freshness.

Model | SW-PL8 |

Single Weight | 100-3000 grams |

Accuracy | +0.1-3g |

Speed | 10-40 bags/min |

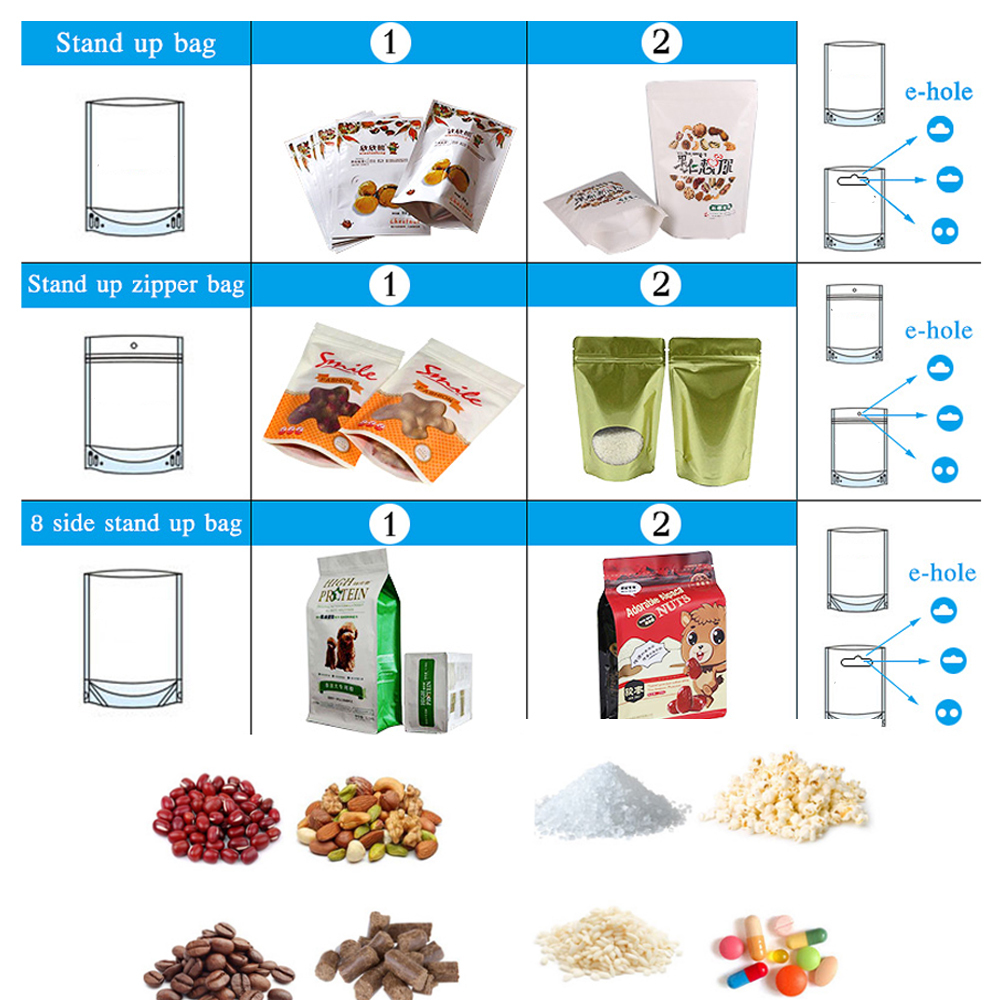

Bag style | Premade bag, doypack |

Bag size | Width 70-150mm; length 100-200 mm |

Bag material | Laminated film or PE film |

Weighing method | Load cell |

Touch screen | 7” touch screen |

Air consumption | 1.5m3/min |

Voltage | 220V/50HZ or 60HZ single phase or 380V/50HZ or 60HZ 3 phase; 6.75KW |

These machines are typically used in a production line for industrial-scale packaging of flour. They can be customized based on the specific requirements of the production line, such as the desired speed of packaging, the volume of flour in each pouch, and the type of pouch material used. Their integration ensures a streamlined process from filling to packaging, significantly enhancing productivity and maintaining consistent quality.

※ Features

◆ Fully automatic packaging machine packing process from raw materials feeding, weighing, filling, sealing to outputting;

◇ Open door alarm and stop machine running in any condition for safety regulation;

◆ 8 station holding pouches finger can be adjustable, convenient for changing different bag size;

◇ All parts can be taken out without tools.

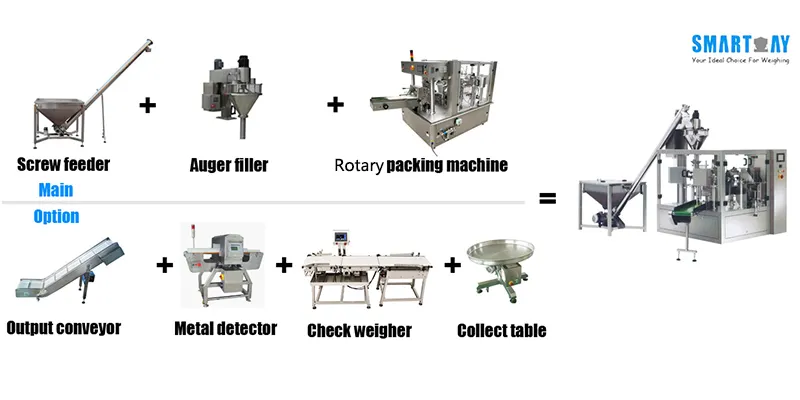

※Packing system composition

1. Weighing Equipment: Auger filler.

2. Infeed Bucket Conveyor: screw feeder

3. Packing machine: rotary packing machine.

※ Application

Flour packaging machine is versatile and can handle a wide range of products beyond just flour, such as coffee powder, milk powder, chili powder and other powder products.

※ Product Certificate

Quick Link

Packing Machine