Custom detergent powder packing machine factory Manufacturer | Smart Weigh

With strong R&D strength and production capabilities, Smart Weigh now has become a professional manufacturer and reliable supplier in the industry. All our products including detergent powder packing machine are manufactured based on the strict quality management system and international standards. detergent powder packing machine We will do our best to serve customers throughout the whole process from product design, R&D, to delivery. Welcome to contact us for further information about our new product detergent powder packing machine or our company.detergent powder packing machine Selected high-quality stainless steel precision casting, simple and stylish appearance, stable and firm structure, wear-resistant and scratch-resistant, durable.

| Model | SW-PL2 |

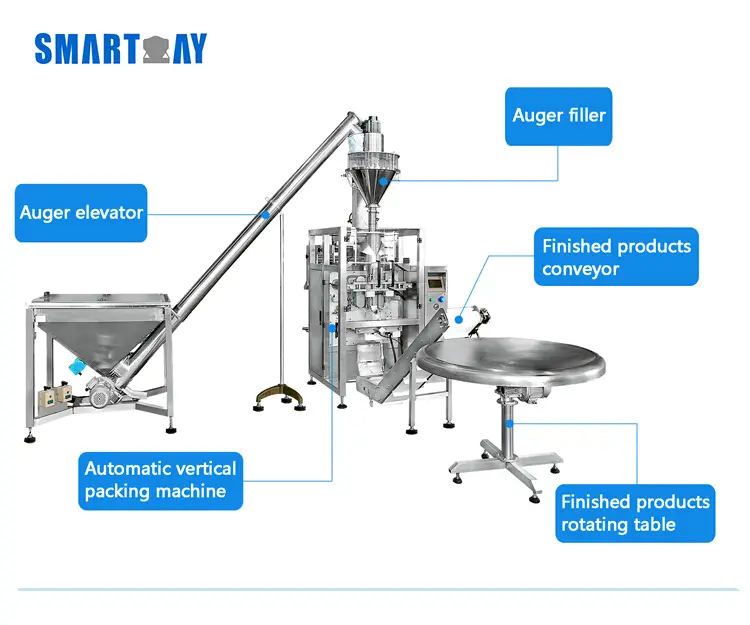

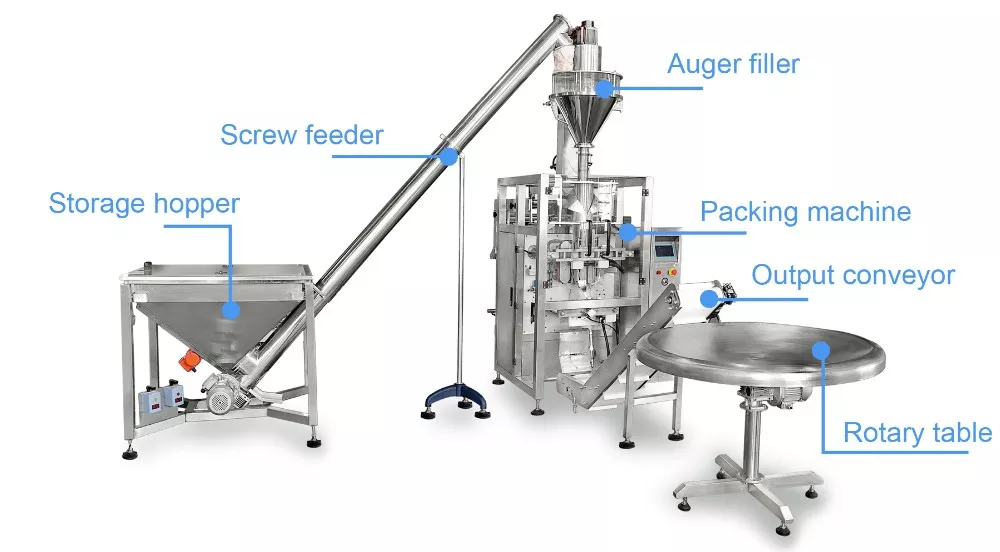

| system | Auger Filler Vertical Packing Line |

| Application | Powder |

| weigh range | 10-3000 grams |

| Accuracy | 士0.1-1.5 g |

| speed | 20-40 bags/min |

| Bag size | width=80-300mm, length=80-350mm |

| Bag style | Pillow bag, gusset bag |

| Bag material | Laminated or PE film |

| control penal | 7" touch screen |

| Power supply | 3 KW |

| Air consumption | 1.5m3/min |

| Voltage | 380V,50HZ or 60HZ, three phase |

sure the machine operates easily and does accurately.

2) The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch..

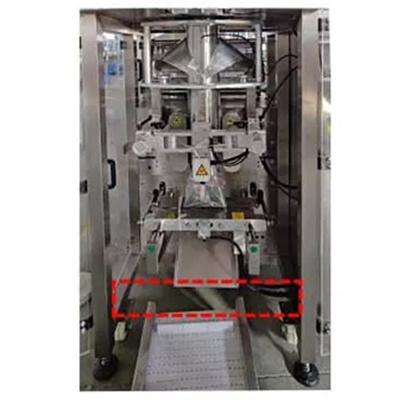

3) Automatic checking system can check bag situation, filling and sealing situation.

The system shows 1.no bag feeding, no filling and no sealing. 2.no bag opening/opening error, no filling and no sealing 3.nofilling, no sealing..

4) The product and pouch contact parts are adopted stainless steel and other advanced material to guarantee the hygiene of

products.

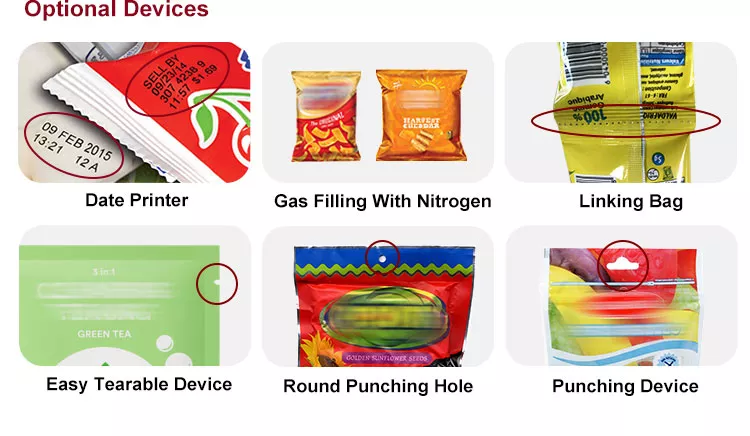

We can customize the suitable one for you according to your requiredment.

Just Tell us : Weight or Bag Size required.

Auger Filler

* Servo motor drive screw.

* Share same touch screen with packing machine, easy to operate;

* Replacing the auger parts, it is suitable for material from super thin powder to granule.

* Hand-wheel button to adjust height.

* Optional parts:like auger screw parts and leakproof acentric device etc.

· Glass window for visible storage,know the feeding level when

machinerunning

· Only 10 minutes to change a new bag former.

· lndividual motor controls the filmstructure, it is good for auto filmcentering.when machine running.

· Roll axle is controlled by pressure:inflate it to fix the film roll , release it to

loose the film roll.

Product detail

Safe and reliable. Small size, light weight,high efficiency,

low energy consumptionand low noise

Accurate positioning, speed setting, stableperformance

packaging molding is more stable

Quick Link

Packing Machine