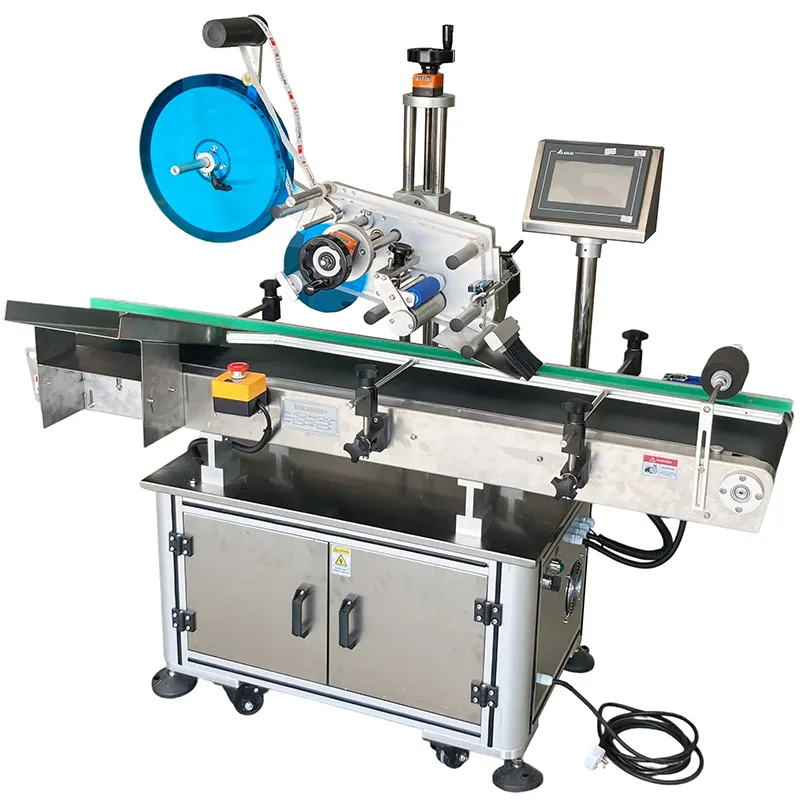

High Precision Barcode Labeling Machine with Inspection Device

Product features

This high precision barcode labeling machine with inspection device features an output conveyor for efficient production line operation. With a labeling precision of ±1mm and adjustable mechanisms, this machine ensures accurate and flexible label placement. The product is equipped with high quality motors and sensors from top brands for reliable performance, making it ideal for various industries with flat surface labeling needs.

Company profile

Our company is a leading manufacturer of high precision barcode labeling machines with inspection devices. With a strong focus on quality and innovation, we strive to provide our customers with cutting-edge technology that ensures accurate and efficient labeling processes. Our team of experts is dedicated to meeting the diverse needs of our clients by continuously researching and developing new features to enhance the performance of our machines. We are committed to providing top-notch customer service and technical support to ensure a seamless experience for our valued customers. Choose us for reliable, state-of-the-art labeling solutions.

Enterprise core strength

Our company is a leading provider of high precision barcode labeling machines with inspection devices. With years of experience in the industry, we specialize in delivering top-quality products that ensure accurate and efficient labeling for a wide range of applications. Our dedication to innovation and customer satisfaction sets us apart, as we continuously strive to exceed expectations and meet the evolving needs of our clients. Trust in our expertise and reliability to streamline your labeling process and enhance productivity. Choose our barcode labeling machine with inspection device for precision, durability, and superior performance.

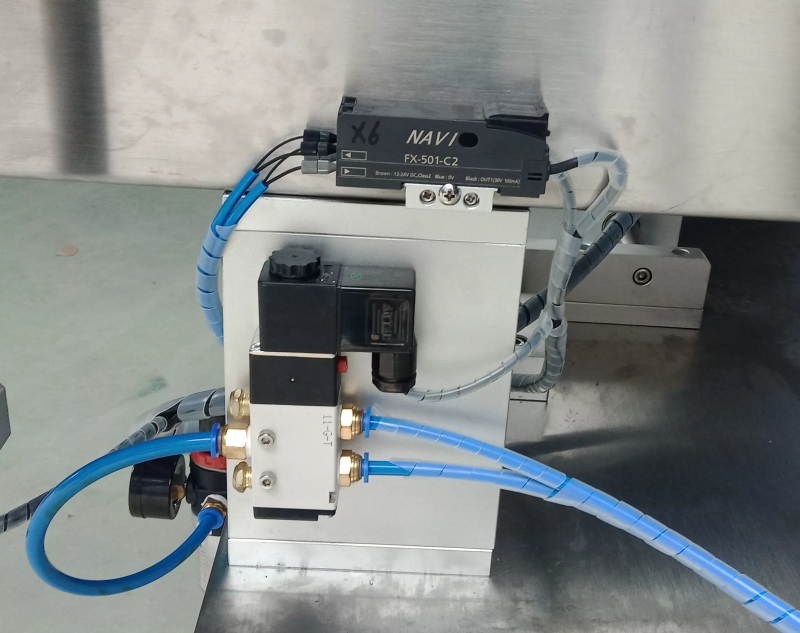

Famous Brand Delta

Human-computer interaction interface with operation teaching function, parameter modification intuitionistic clear, various functions switching simple

Label detection electric eye, product detection electric eye and optical fiber amplified adopts famous brands such as Germany SICK, Japan PANASONIC, Germany LEUZE (For transparent sticker) etc.

High Efficiency Production Line

High efficiency with good labeling effect, can save consumable and labor cost, so now self-adhesive labeling machine has been more and more popular in market;

Labeling machine often match with other machines auch as weight packing machine, cap sorter and capping machine, can seaming machine, cover impressing machine, weight checker, foil sealing machine, metal detector, inkjet printer, box packing machine and other machines to combine all kinds of production lines according to requirements.

1. It can label for any products with flat surface. More flexible arrangement for manufacturing schedule.

2. The labeling head convenient to adjust, the labeling speed is automatically synchronous with the conveyor belt speed to ensure precise labeling.

3. The speed of conveyor line, the speed of pressure belt and the speed of label output can be set and changed by the PLC human interface.

Flat surface plane labeling machine can work for all kinds of objects with plane, flat surface, side surface or large curvature surface such as bags, paper, pouch, card, books, boxes, jar, cans, tray etc.Widely used in food, medicine, daily chemical, electronic, metal, plastics and other industries. It has optional date coding device, realize date coding on stickers.

Quick Link

Packing Machine