Practical ladders and platforms manufacturing | Smart Weigh

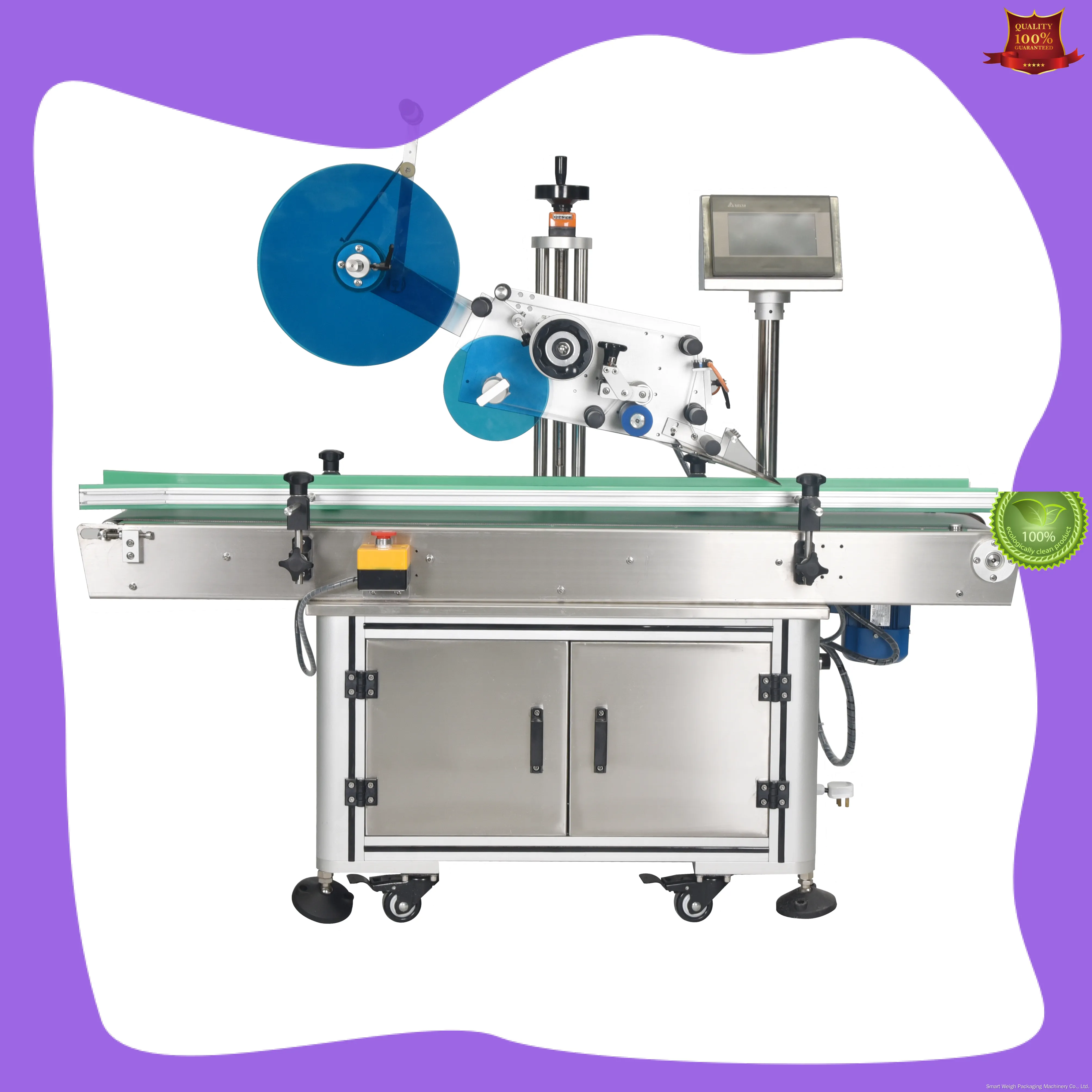

Always striving toward excellence, Smart Weigh has developed to be a market-driven and customer-oriented enterprise. We focus on strengthening the capabilities of scientific research and completing service businesses. We have set up a customer service department to better provide customers with prompt services including order tracking notice. ladders and platforms We promise that we provide every customer with high-quality products including ladders and platforms and comprehensive services. If you want to know more details, we are glad to tell you.A huge amount of labor cost can be saved by using this product. Unlike the traditional drying methods which need frequent drying in the sun, the product features automation and smart control.

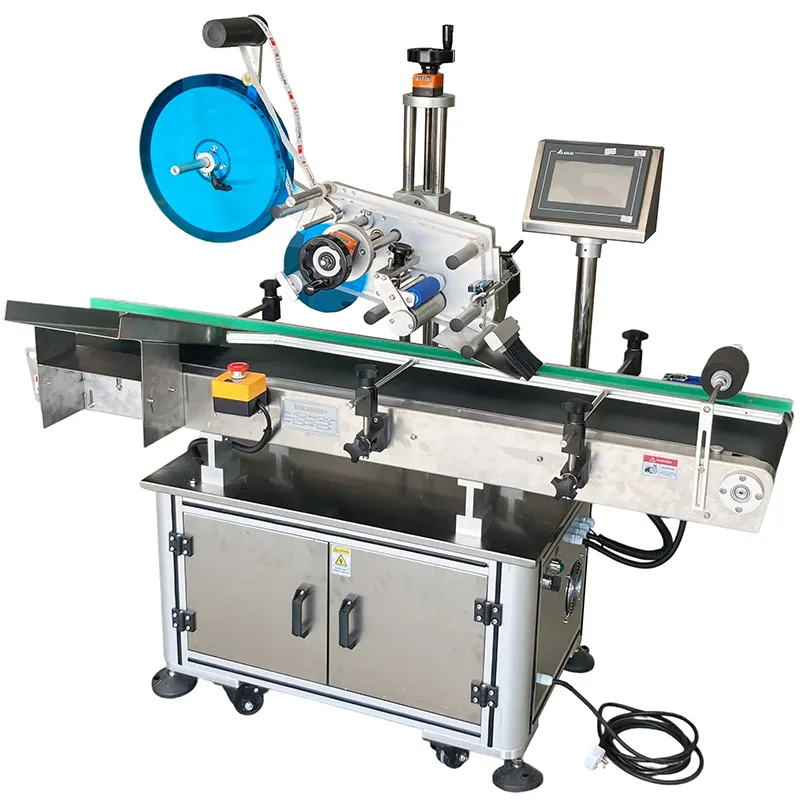

Famous Brand Delta

Human-computer interaction interface with operation teaching function, parameter modification intuitionistic clear, various functions switching simple

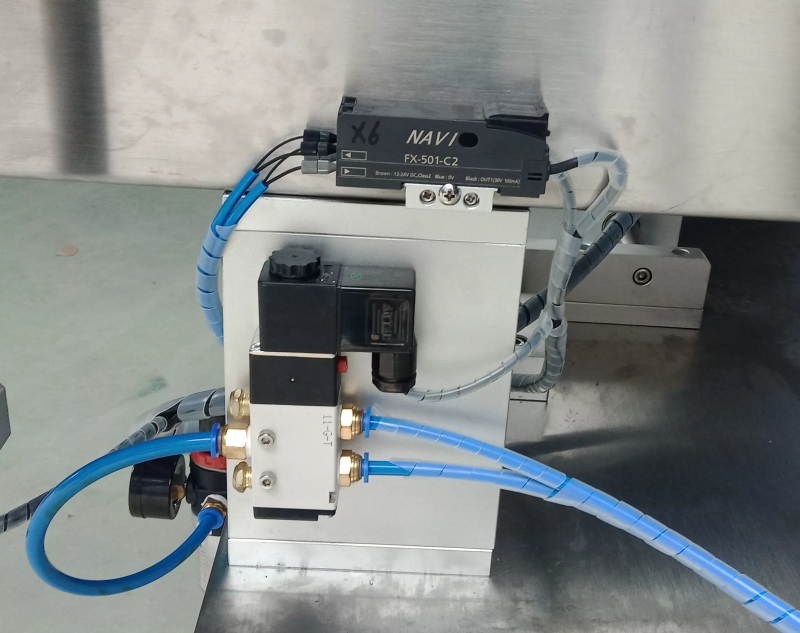

Label detection electric eye, product detection electric eye and optical fiber amplified adopts famous brands such as Germany SICK, Japan PANASONIC, Germany LEUZE (For transparent sticker) etc.

High Efficiency Production Line

High efficiency with good labeling effect, can save consumable and labor cost, so now self-adhesive labeling machine has been more and more popular in market;

Labeling machine often match with other machines auch as weight packing machine, cap sorter and capping machine, can seaming machine, cover impressing machine, weight checker, foil sealing machine, metal detector, inkjet printer, box packing machine and other machines to combine all kinds of production lines according to requirements.

1. It can label for any products with flat surface. More flexible arrangement for manufacturing schedule.

2. The labeling head convenient to adjust, the labeling speed is automatically synchronous with the conveyor belt speed to ensure precise labeling.

3. The speed of conveyor line, the speed of pressure belt and the speed of label output can be set and changed by the PLC human interface.

Flat surface plane labeling machine can work for all kinds of objects with plane, flat surface, side surface or large curvature surface such as bags, paper, pouch, card, books, boxes, jar, cans, tray etc.Widely used in food, medicine, daily chemical, electronic, metal, plastics and other industries. It has optional date coding device, realize date coding on stickers.

Quick Link

Packing Machine