Product advantages

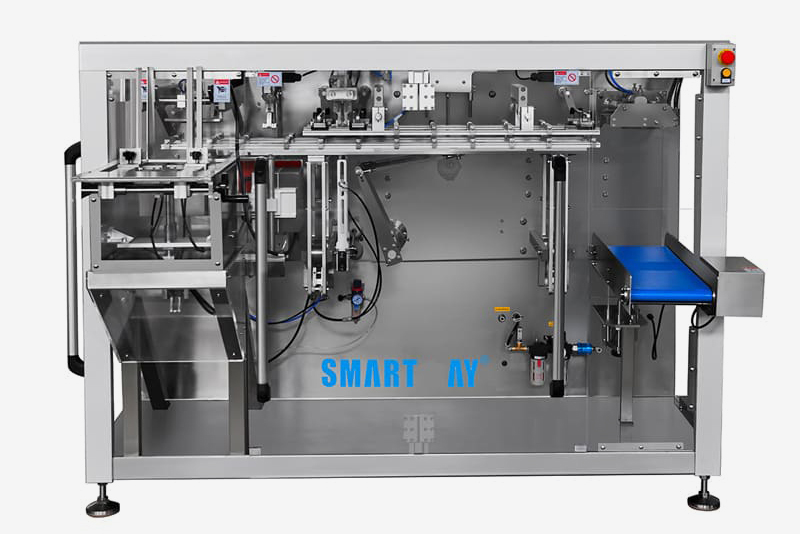

The Smart Weigh Vertical Doypack Packaging Machine combines advanced technology with a durable design to deliver precise and efficient packaging solutions. Renowned for its versatility, this machine supports various pouch sizes and materials, ensuring consistent sealing and accurate weighing for diverse product types. Key features include user-friendly controls, high-speed operation, and minimal maintenance requirements, making it ideal for boosting productivity and reducing downtime.

Team strength

Our Smart Weigh Vertical Doypack Packaging Machine is backed by a dedicated team of industry experts specializing in packaging technology and automation. With years of experience, our engineers and technicians ensure precision, efficiency, and innovation in every unit. The team’s commitment to quality control and continuous improvement guarantees a reliable, high-performance machine suited for diverse packaging applications. Their collaborative approach enables rapid problem-solving and seamless customization, adding exceptional value to your production line. This strong, skilled team empowers us to deliver a versatile packaging solution that maximizes productivity and supports your business growth with confidence.

Enterprise core strength

Our team behind the Smart Weigh Vertical Doypack Packaging Machine combines industry expertise, innovative engineering, and dedicated customer support to deliver unmatched product quality and reliability. With skilled professionals focused on precision and efficiency, the team ensures each machine meets rigorous standards for versatile packaging solutions. Their commitment to continuous improvement and responsive service empowers businesses to enhance productivity while minimizing downtime. This strong technical foundation and collaborative approach make the team a vital asset, driving innovation and seamless integration, ultimately providing customers with a packaging machine that balances performance, durability, and ease of use.

Discover the efficiency and versatility of our doypack packing machines, designed to meet the diverse needs of the packaging industry. Forming the bag from roll of film, accurately dosing the product into the formed pouch, sealing it hermetically to ensure freshness and tamper evidence, then cutting and discharging the finished packs. Our machines provide reliable and high-quality packaging solutions for a wide range of products, from liquids to granules.

Doypack packaging machine types

bg

Rotary doypack packaging machine

They work by rotating a carousel, which allows numerous pouches to be filled and sealed at the same time. Its fast functioning makes it ideal for large-scale production applications where time and efficiency are critical.

Model

| SW-R8-250 | SW-R8-300

|

| Bag Length | 150-350 mm | 200-450 mm |

| Bag Width | 100-250 mm | 150-300 mm |

| Speed | 20-45 packs/min | 15-35 packs/min |

| Pouch Style | Flat pouch, doypack, zipper bag, side gusset pouches and etc. |

Horizontal doypack packaging machine

Horizontal pouch packing machines are designed for easy operation and maintenance. They are particularly effective for packaging flat or relatively flat products.

| Model | SW-H210 | SW-H280 |

| Pouch Length | 150-350 mm | 150-400 mm |

| Pouch Width | 100-210 mm | 100-280 mm |

| Speed | 25-50 packs/min | 25-45 packs/min |

| Pouch Style | Flat pouch, doypack, zipper bag |

Mini doypack packaging machine

Mini pre made pouches packing machines are the perfect solution for small-scale operations or businesses that require flexibility with limited space. They are ideal for startups or small businesses that need efficient packaging solutions without the large footprint of industrial machines

| Model | SW-1-430 |

| Pouch Length | 100-430 mm

|

| Pouch Width | 80-300 mm |

| Speed | 15 packs/min |

| Pouch Style | Flat pouch, doypack, zipper bag, side gusset pouches and etc. |

Doypack Pouch Packing Machine Features

bg

1. Enhanced Product Presentation

Doypack packing machines are designed to produce attractive, marketable stand-up pouches. These pouches offer considerable space for branding and labeling, making them ideal for products that need to stand out on retail shelves. The aesthetic attractiveness of doypack packaging can improve product visibility and consumer appeal, which is critical for retail success.

2. Versatility and Flexibility

Doypack filling machines are extremely adaptable and can handle a broad variety of materials such as liquids, granules, powders, and solids. This adaptability enables businesses to use a single machine for many items, avoiding the need for different packaging equipment. Furthermore, these machines can accommodate a wide range of bag sizes and kinds, including those with zippers, spouts, and resealable features, providing further customization possibilities to fulfill specific packaging requirements.

3. Efficiency and Cost-Effectiveness

The automated features, such as bag size adjustment and accurate temperature control, eliminate manual involvement and the risk of errors, resulting in lower labor costs and less material waste.

4. Durability and Low Maintenance

Doypack machines are constructed from strong materials and components, ensuring long-term dependability and durability. Stainless steel design and high-quality pneumatic components ensure long-lasting and reliable performance. Many machines include self-diagnostic instruments and replaceable parts, simplifying maintenance and reducing the danger of unexpected malfunctions.

Our doypack packaging machines are ideal for packaging snacks, beverages, pharmaceuticals, and chemical items, catering to a wide range of sectors. Whether you're packing powders, liquids, or granulated items, our equipment perform exceptionally.

![food doypack packaging]()

Choose from a range of fillers and accessories to customize your doypack machine weighing packing line. Options include auger fillers for powder products, volumetric cup fillers for grains, and piston pumps for liquid products. Additional features such as gas flush and vacuum sealing are available to meet your specific packaging needs.