Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

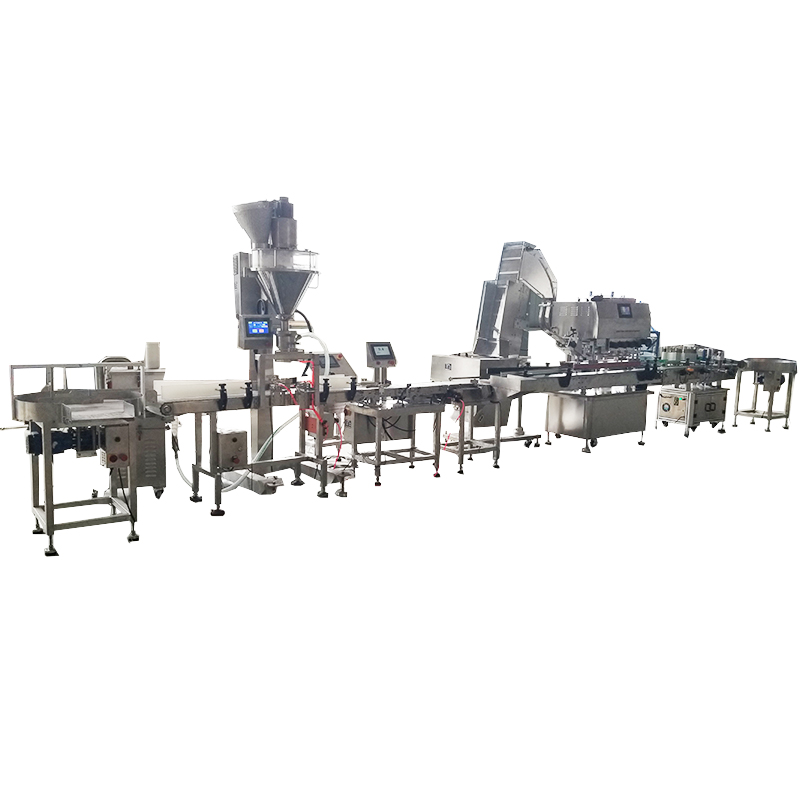

Bottle conveying filling capping sealing packaging machine with auger filler for protein powder

Bottle packing line for powder.

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

More Choices

※ Structure and performance specification:

1. Empty tin can feeding machine

2. Milk powder weighing filling machine

3. Checkweigher

4. Can capping sealing machine

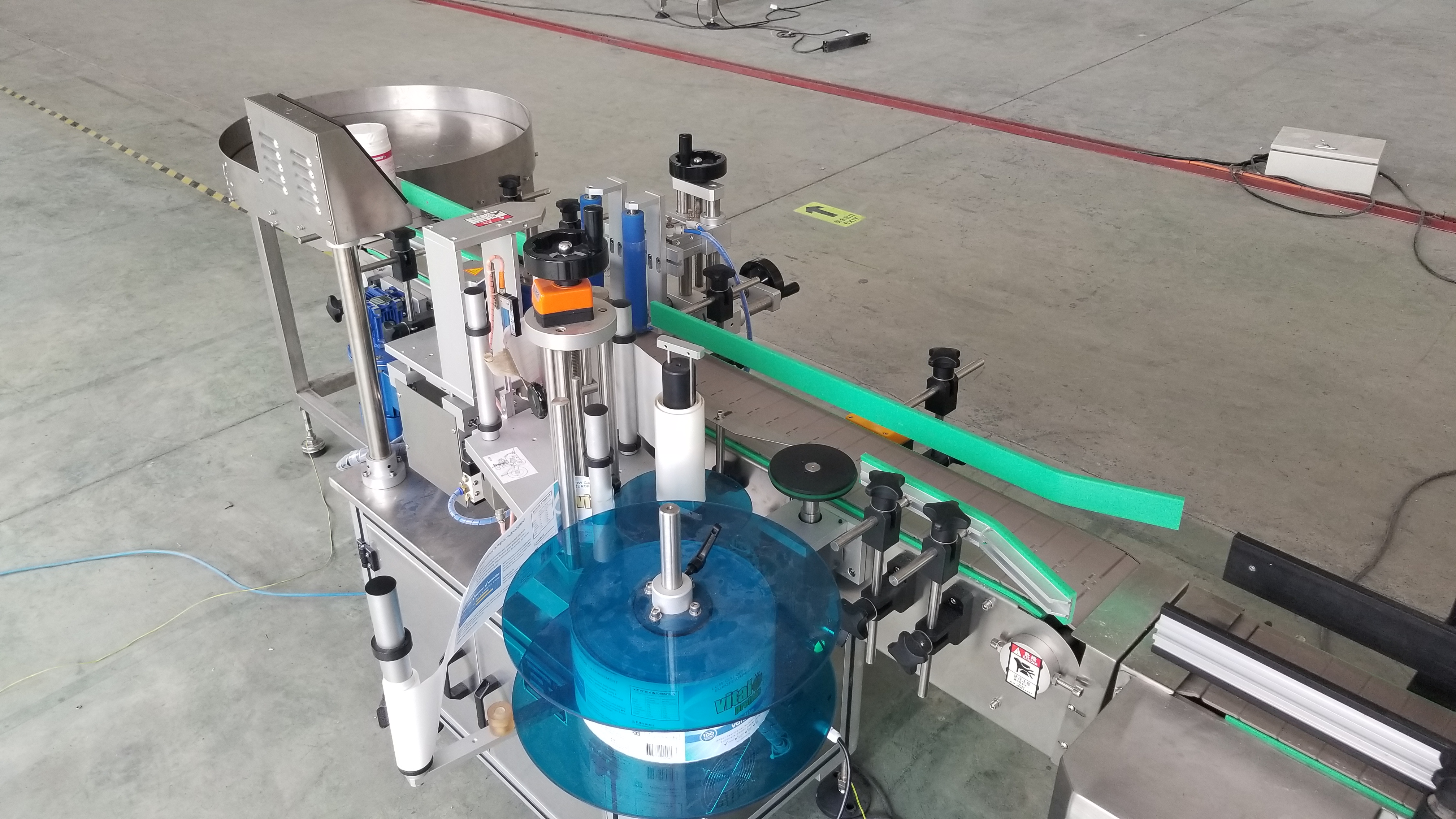

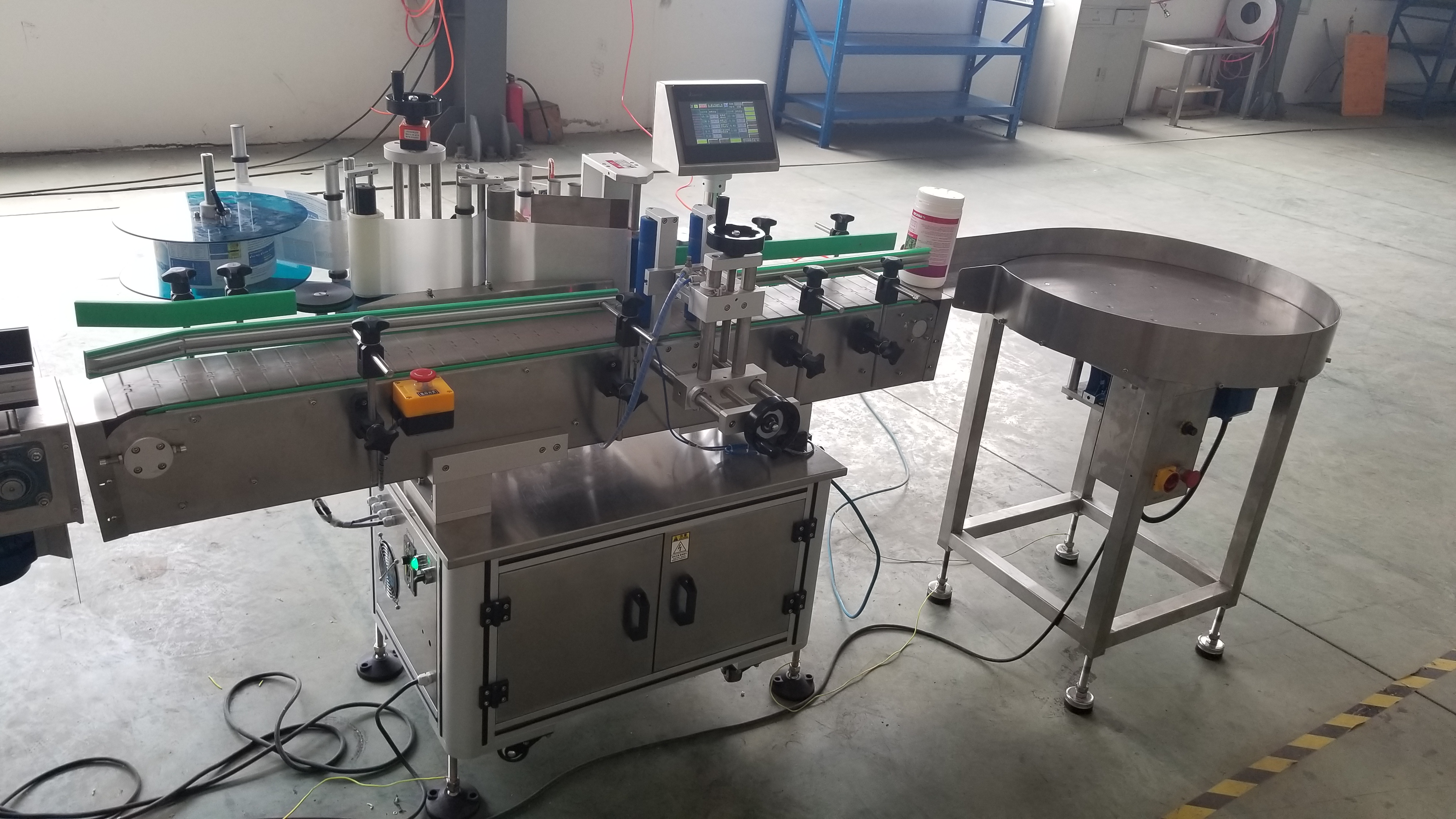

5. Labeling machine

6. Collect table

| Weigh Range | 10-1000g (10 head); 10-2000g (14 head) |

|---|---|

| Accuracy | ±0.1-1.5g |

| Speed | 20-60 bpm |

| Container Style | Tinplate Can, Plastic Jar, Glass Bottle, etc. |

| Container Size | Diameter=30-130 mm, Height=50-220 mm (depends on machine model) |

| Packing Material | Tinplate, Aluminum, Plastic, Glass and etc. |

| Weighing Method | Load Cell |

| Control Panel | 7" Touch Screen |

| Voltage | 220V/50HZ or 60HZ, Single Phase |

※ Features:

1.The machine is controlled by PLCsystem and touch screen.

2.The production capacity and automation are very high.So the labor cost can be saved.It is applicable to be part of packaging system.

3.Irrotional design is adopted for cans during the seaming and the processing accuracy is high.The seaming quality is superior other products.

4.The machine is applicable for sealing of various tin cans,aluminum cans,paper cans and all kinds of round cans.It is simple in operation and it is an ideal packing equipment of food,beverage,pharmaceutical and the other industry.

※ Machine details

※ Application

Suitable for a variety of cans including plastic cans, tinplate cans, aluminum cans, paper cans, and etc and widely applicable in food, beverage, and pharmaceutical industries.

※ Product Certificate

b

b

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425