Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

The ready-to-eat meal industry has become increasingly competitive as the demand for convenience and healthy food options continues to rise. In this market, meal packaging efficiency and quality can make or break a business. Investing in a high-quality meal packaging machine is critical for any ready-to-eat meal business looking to stay ahead of the competition. Not only can it help increase production speed and efficiency, but it can also ensure the freshness and quality of the food being packaged. This article will explore the importance of upgrading your meal packaging machine and how it can positively impact your business's success.

The Importance of Upgrading Your Meal Packaging Machine

Upgrading your meal packaging machine is critical for the success of your ready-to-eat meal business. An upgraded machine can increase production speed and efficiency, allowing you to meet the demands of a competitive industry. It can also improve the quality and freshness of your food, ensuring customer satisfaction and repeat business. Furthermore, an upgraded machine can enhance food safety and compliance with regulations, protecting both your customers and your business. By lowering maintenance and repair costs, upgrading your meal packaging machine can also help you save money in the long run. Overall, investing in an upgraded meal packaging machine is a smart business decision that can positively impact your bottom line and set you apart from the competition.

Benefits of Upgrading Your Meal Packaging Machine

Upgrading your meal packaging machine offers several benefits that can positively impact your business.

· Firstly, an upgraded machine can increase production speed and efficiency, allowing you to pack more food in less time. This can help you meet the demands of a growing customer base and increase your revenue.

· Secondly, an upgraded machine can improve the quality and freshness of your food, ensuring customer satisfaction and repeat business. A well-functioning machine can also help you reduce waste and save money on spoiled or damaged food.

· Additionally, an upgraded machine can enhance food safety and compliance with regulations, protecting your customers and business from potential health risks and legal issues.

· Finally, upgrading your machine can lower maintenance and repair costs, as new machines often require less maintenance and are less prone to breakdowns.

By investing in an upgraded meal packaging machine, you can enjoy these benefits and more, helping your ready-to-eat meal business succeed in a competitive industry.

Choosing the Right Meal Packaging Machine for Your Business

Choosing the right meal packaging machine for your business is crucial to ensure optimal performance and efficiency. Firstly, you must evaluate your needs and requirements, such as:

· The type of food you are packaging

· The volume of production

· The types of packaging materials and formats required

This will help you determine the size, speed, and capacity of the machine you need.

Once you have evaluated your needs, you should compare different models and brands of meal packaging machines. Look for machines specifically designed for your type of food and packaging requirements. Compare features such as:

· Speed

· Accuracy

· Flexibility

· Durability

· The cost and maintenance requirements of each machine

It would be best if you also considered the machine's compatibility with your existing production line and equipment.

It is also advisable to consult with industry experts or manufacturers to help you choose the right meal packaging machine for your business. Experts can provide valuable advice and recommendations based on their experience and knowledge of the industry. Manufacturers can also provide detailed information about their machines and help you select the right one for your business.

Finally, when deciding, you should consider your budget and long-term goals. While it may be tempting to choose the least expensive machine, you should also consider each option's long-term costs and benefits. Look for a machine that provides the best value for your investment and can help you achieve your long-term goals, such as increased production, improved quality, and enhanced food safety.

Common Types of Meal Packaging Machines

Several types of meal packaging machines are available on the market, each designed for specific packaging needs. Some of the most common types of meal packaging machines are:

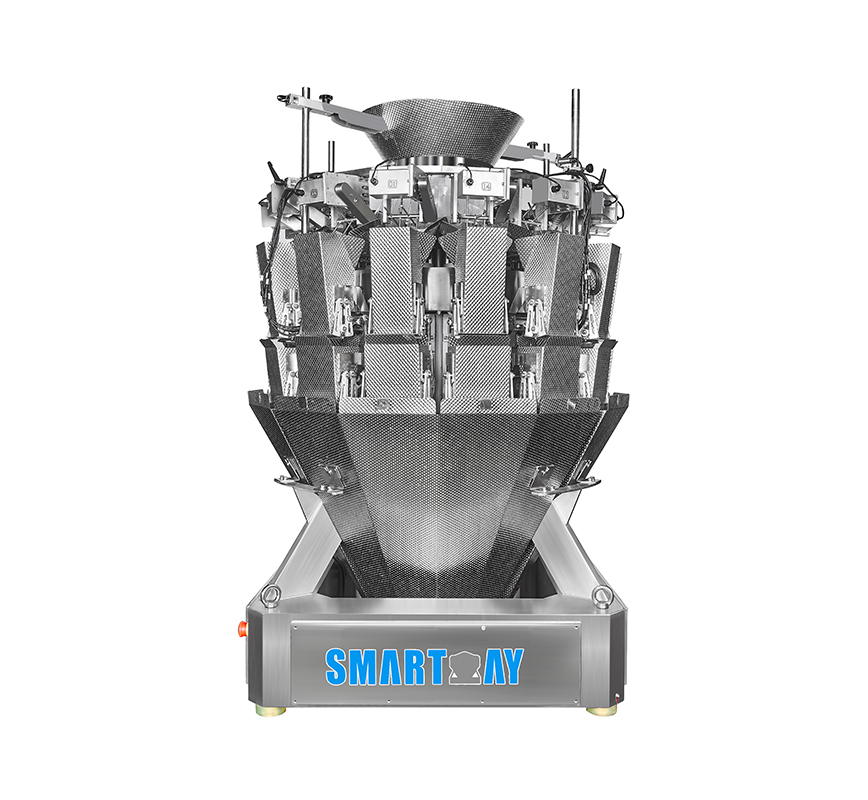

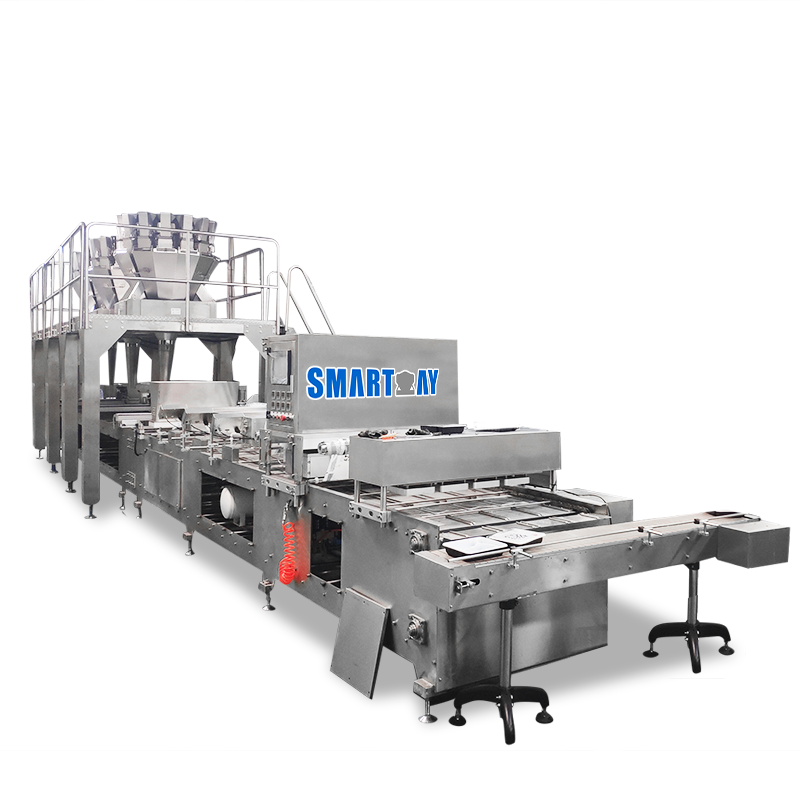

Multihead weighing machines

These machines play an weighing and filling role in the meals packaging machine system. On the way to full automation packing process of meal packing, the most challenage is the auto weighing and filling.

Vacuum packaging machines

These machines remove air from the packaging material before sealing it, creating a vacuum-sealed package that helps preserve the food's freshness and flavor. Vacuum packaging machines are commonly used for meat, fish, and dairy products.

Tray sealing machines

These machines use a film to cover a tray or container and then heat or pressure seal the film to the tray. Tray-sealing machines are commonly used for pre-packaged meals, snacks, and produce.

These machines auto pick and open premade retort bags, fill it with the product, and seal it. Rotary pouch packing machines are commonly used for ready to eat products like pickle food(like kimchi), fried rice and etc.

Tips for Upgrading Your Meal Packaging Machine

When upgrading your meal packaging machine, there are several tips to remember.

· Firstly, conduct thorough research to identify the latest technology and features available to meet your needs.

· Secondly, consult with industry experts or packaging machine manufacturers to ensure you choose the right machine for your business.

· Thirdly, consider the new machine's cost and return on investment, including factors such as increased production, reduced maintenance costs, and improved product quality.

· Fourthly, train your staff to operate and maintain the new machine properly to maximize its performance and lifespan.

By following these suggestions, you can ensure a smooth and successful upgrade of your meal packaging machine and enjoy the benefits of improved efficiency and profitability in your business.

Conclusion

In conclusion, upgrading your meal packaging machine is critical for the Survival of your ready-to-eat meal business. Investing in a new or upgraded machine can increase production speed, improve the quality and freshness of your food, enhance food safety and compliance with regulations, and reduce maintenance and repair costs. Choosing the right meal packaging machine for your business requires careful evaluation of your needs and requirements, comparison of different models and brands, and consultation with industry experts or packaging machine manufacturers. As the food packaging industry evolves, staying up-to-date with the latest technology and advancements in food packaging machines is paramount to remaining competitive. Investing in a meal packaging machine can help your business succeed in a fast-paced industry and meet the demands of your customers. Thanks for the Read!

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved