6 Tips to Keep Your Packaging Machine Running Smoothly

Packaging is one of the most important aspects of making your products more attractive and making your business more successful. There are a lot of benefits of efficient packaging, as it can have a positive impact on your business.

Packaging can be done more conveniently and effectively with a packaging machine. Packaging machines can benefit a business in many different ways. However, there can be some incidents where the packaging machine can be disturb the process. To have a proper and smooth packaging process, taking care of the machine and doing proper maintenance is essential. Here we have mentioned some tips and tricks to make your packaging machine run smoothly.

6 Tips and Tricks to keep your Packaging Machine Run Smoothly:

1. Installation:

The first and foremost thing you must ensure is that the machine's setup is done correctly. When the machine is installed properly, then only it works adequately and gives the best results. Ensure that you have experts available so that if you face any problem with the installation, you can quickly get it checked before it affects the working of the entire machine.

2. Keep the Packaging Machine Line Cleaned:

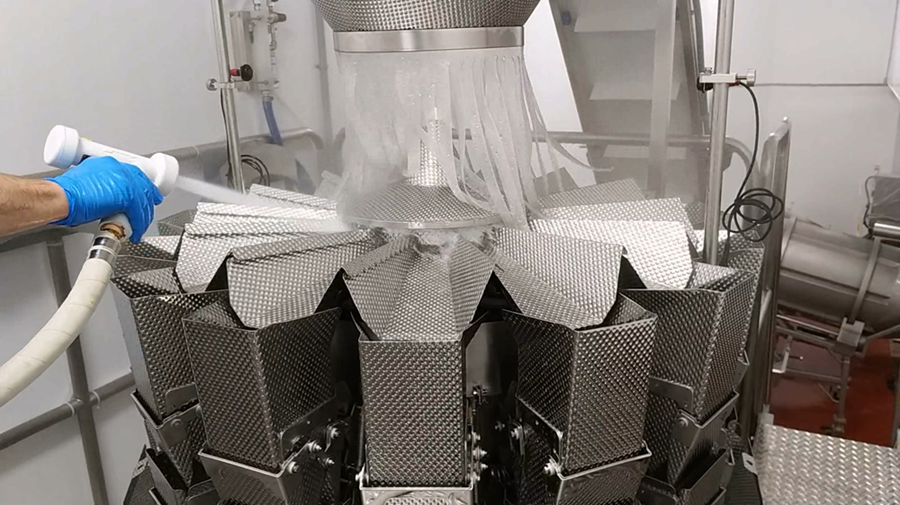

Keeping the line clean is very important. This does not mean removing the bigger and chunkier garbage from the weighing and packing machines. Instead, you need to do scheduled deep cleaning of the time. Deep cleaning should e done as needed or when you feel your machine is not working smoothly.

There are different ways through which you can clean the parts of the machine. You can either use a pressure wash to clean the food contact parts or pressurized air to remove the dirt and dust particles from the machine. Regular cleaning should be done daily, whereas this deep cleaning should be done weekly or monthly. Cleaning the machine will boost its performance, preventing any breakage and further damage to the machine.

3. Training the Employees:

Another vital point to remember when you have a machine working is that the person who works on the machine should be educated. This means the employees who are working on the machine and around it should know everything about it. They should know how to work on it, the things that will make it run smoothly, and even the things that should not be done on the machines.

The learning process should also include the injuries that can be caused by the machine and the precautional measures. All of this is the main factor in boosting the performance of the machine and also helps with the success of the company.

4. Maintenance:

Ensure that you have scheduled proper maintenance sessions for the packaging machines. This maintenance should be done by a professional who knows everything about the machine. If any parts are rusted, they should be changed immediately. If there are any loose wires, fix them, and all the other problems should be resolved quickly to optimize the machine's performance.

5. Keeping Parts in Stock:

You must keep the essential parts of the packaging machine always in stock. There might be situations where the part stop working, and you'll need to change it immediately. If you don't have the parts in stock, your entire work process will be halted when your machine is in problem, and you won't be able to achieve your daily target. If you want your machine to run smoothly, always have spare parts in stock.

6. Collaborating with Professionals:

Make sure you always have professional experts who can help you with the machine. There can be problems that the employees cannot fix; here, only professionals can do the work and replace or fix the machines. Ensure that the place you are getting the machine from is providing customer services even after the sales.

Conclusion:

We hope this article was beneficial for enhancing the performance of the packaging machines. If you are on the hunt for a good packaging machine, then Smart Weigh is a fantastic option. They have many kinds of machines, such as vertical packaging machines, multihead weighers, pouch packing machines, and many others.

This is a high-end brand that provides the best quality packaging machine to customers. Hence, this is the perfect platform to invest in packaging machines. Over 1000 of Guangdong Smart weigh pack's systems have been deployed in more than 50 different countries, making it a top manufacturer of Smart Weigh Packing Machines that integrate food processing and packaging solutions.

Author: Smartweigh–Multihead Weigher

Author: Smartweigh–Multihead Weigher Manufacturers

Author: Smartweigh–Linear Weigher

Author: Smartweigh–Linear Weigher Packing Machine

Author: Smartweigh–Multihead Weigher Packing Machine

Author: Smartweigh–Tray Denester

Author: Smartweigh–Clamshell Packing Machine

Author: Smartweigh–Combination Weigher

Author: Smartweigh–Doypack Packing Machine

Author: Smartweigh–Premade Bag Packing Machine

Author: Smartweigh–Rotary Packing Machine

Author: Smartweigh–Vertical Packaging Machine

Author: Smartweigh–VFFS Packing Machine

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine