A Buyer's Guide to Rice Packing Machine

Rice packing machines have transformed the food packaging industry. These machines boost operational efficiency and deliver consistent quality standards. A well-maintained machine works reliably for 10-15 years, which makes it a valuable long-term investment for businesses.

The original cost might seem high, but rice packaging machines provide substantial benefits through better productivity and lower operational costs. These automated systems handle packaging styles of all types - from pillow bags to gusseted bags and vacuum-sealed pouches. The machines ensure precise weight measurements regardless of package size.

This article explores everything business owners need to know about selecting the right rice bag packing machine from understanding different types and key features to maintenance requirements and long-term benefits.

What Are Rice Packing Machines?

A rice packing machine is a specialized equipment that protects rice products through automated packaging processes. The systems consist of a variety of components working in unison to ensure smooth functioning of the packaging.

The core parts of a rice bagging machine include:

● A storage hopper for holding rice for dispensing

● A precision weighing scale for accurate measurements

● A filling machine for stuffing rice into packages

● A sealing tool for securing packages

● An integrated conveyor goods movement system

On top of that, modern rice bag packing machines come with digital controls and automated systems that can handle eight to twelve bags per minute. The machinery keeps the quality of the product intact by not letting moisture leak, protecting against exposure to air, and against contamination with microbes.

Rice packing machinery packs not only rice. Rice filling machine has a very significant function of simplifying day-to-day processes for packagers and packers of rice. Rice packing machinery keeps pack weight constant, meets the requirements of hygiene, and minimizes waste of material considerably when packing.

Rice packing machinery has been rendered necessary for utilization in rice mills, pack foods companies, super markets, and small-scale rice industries. The machinery works with different pack materials including jute sacks, polypropylene sacks, and packets for different purposes of the markets.

Types of Rice Packaging Machines

Rice packaging industry provides many options, from simple manual systems to sophisticated automated solutions. The choice mostly depends on production volume, budget constraints, and specific packaging requirements.

▶1) Manual vs. Automatic Rice Packing Machines

Small-scale operations benefit from manual packing systems where human operators handle filling and sealing processes. These systems need minimal upfront investment but process fewer bags per hour than automated alternatives. Automatic systems have become popular because they can process up to 2400 bags per hour. They also provide better precision and lower labor costs.

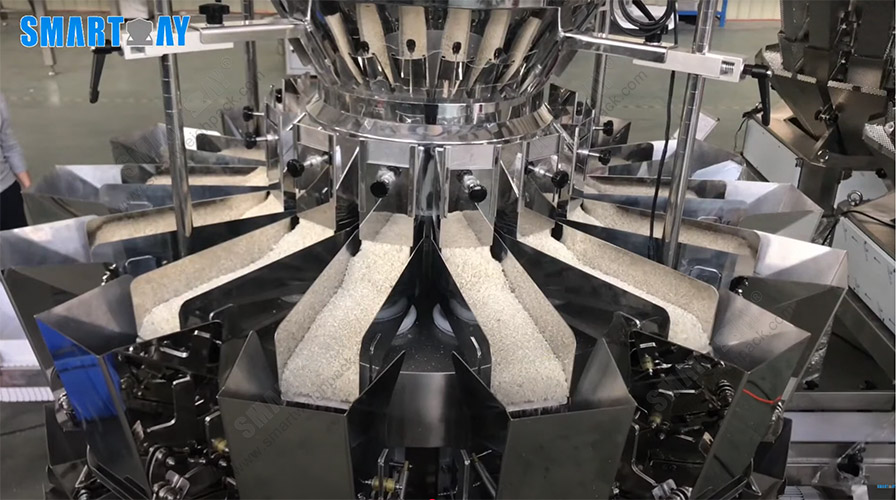

▶2) Multihead Weigher Vertical Packing Machine for Rice

Multihead weigher systems excel at handling granular products with exceptional accuracy. These machines use multiple weigh heads to generate precise measurements that ensure consistent package weights. The Rice Multihead Weigher from Smart Weigh is unique due to its anti-leaking feature, which also maintains ideal output speeds while enhancing accuracy and speed.

Rice Multihead Weigher works with VFFS machines represent innovative rice packaging technology. These systems create bags from roll stock film and can handle package sizes from 100g to 5kg. In spite of that, their most notable feature is versatility.

▶3) Rotary Packaging Machines for Rice

Eight stations in rotary packaging systems handle pre-made pouches, including flat and stand-up varieties. These machines blend naturally with various filling mechanisms. Their touch screen interfaces provide precise control and boost operational efficiency.

Key Factors to Consider When Choosing a Rice Packing Machine

The right rice bagging machine can make or break your operations. You need to evaluate several key factors that affect your success.

● Package Style: The style of the package is an important consideration for branding and shelf presentation. Some machines offer the ability to pack rice in various forms, such as pillow bags, gusset bags, or stand-up pouches. Consider your branding goals, storage, and handling preferences to choose a machine that accommodates the desired package style.

● Packaging Speed & Capacity: The machine's packaging speed determines your production's efficiency. Today's machines can pack 900 to 1400 bags every hour. Advanced systems handle package sizes from 5 to 25 kg.

● Accuracy & Precision: Weight consistency depends on precision weighing mechanisms. The latest machines have three-sensor weighing structures and automatic error correction systems. These features help reduce product waste and maintain strict quality control.

● Flexibility: A good rice bag packing machine should provide flexibility in handling different packaging materials and bag sizes. If a business packs different types of rice or uses various bag styles, it’s important to choose a machine that can easily adjust to these needs.

● Automation & Integration: Modern systems connect through RS232/485 serial ports for data communication. PLC-based controls with touch screen interfaces let you track package weights and production rates immediately.

● Durability & Maintenance: Your machine will last longer with scheduled maintenance. Food-contact parts built from stainless steel stop residue buildup. Closed studio designs shield against rodent damage and acid corrosion. The machine runs continuously with minimal downtime when you regularly check wear parts and maintain proper lubrication.

Benefits of Using Automated Rice Packaging Machines

Automated rice packaging machines lead the vanguard of modern food processing and provide substantial benefits to manufacturers and processors.

✔1) Increased efficiency and reduced labor costs

These automated systems work at impressive speeds and process between 900-1,400 bags per hour. The machines handle multiple tasks at once as they measure, bag, and seal products. Production facilities can recover their costs within two years through streamlined processes and labor savings.

✔2) Consistency in weight and packaging

Consistency in weight and packaging is important for quality and customer trust. Advanced weighing systems help by using high-precision sensors to ensure accurate weight control. They also have automatic error correction to fix mistakes and quality monitoring to keep everything uniform. This reduces waste, improves efficiency, and ensures products meet industry standards.

✔3) Reduced material waste

Automated packaging systems cut product loss with exact portioning and sealed containment. These machines help you retain control of inventory by preventing spillage and ensuring accurate measurements. The systems also provide better traceability features that track production details like weight, time, and operator information.

✔4) Compliance with food safety regulations

Automated systems are CE Certificate. The machinery also has sanitary design to uphold a standard of cleanliness. The systems also include enhanced systems for tracing critical points of control and upholding the quality of the product when packaged. The overall approach towards quality and safety ensures strict regulations are met and safety for consumers.

How to Maintain a Rice Packing Machine for Optimal Performance?

Proper maintenance is the lifeblood of a rice packaging machine's longevity. Some well-maintained units have stayed operational for 50+ years.

◆1) Regular cleaning and inspection

A well-laid-out maintenance schedule will give a better performance. Daily tasks include hoovering loose particles and inspecting hoppers, chutes, and sealing units. Weekly procedures need thorough cleaning with non-abrasive cleaners and checking belts, gears, and bearings. Operators must pay attention to areas where rice tends to build up, such as infeed hoppers and filling mechanisms.

◆2) Troubleshooting common issues

Fixing common issues in packaging and weighing systems is important for smooth operations. Sometimes, materials get stuck in hoppers and chutes, causing jams. If sealing units are not set right, packages may leak. Worn-out scales can lead to uneven weights, and poor cleaning can cause contamination. Mechanical stress may also break grains. Regular maintenance, proper adjustments, and keeping equipment clean help prevent these problems and keep everything running smoothly.

◆3) Manufacturer support and spare parts availability

Quality replacement parts are vital for regular maintenance. Original manufacturer parts deliver optimal performance and durability. Parts management programs help prevent unexpected downtimes. Manufacturers provide customized support through E-portals that give quick access to technical documentation and spare parts inventory management. This approach reduces production interruptions and makes equipment last longer.

Why Choose Smart Weigh Pack for Rice Packaging Machines

Smart Weigh Pack is a well-known international manufacturer of quality rice packing machinery, with best-of-the-line automation for precise and effective packing. With experience of more than ten years, we are experts in supplying fully automatic solutions for accuracy, speed, and longevity. Our rice bagging machine can be designed for different grains, with minimal breakage and accurate weight measurement.

We integrate preformed pouches, vertical form-fill-seal (VFFS) equipment, and multihead weighers for varying package requirements, from small retail packs to industrial-size packages. Smart Weigh Pack also offers intuitive interfaces, easy maintenance, and low-energy configurations for higher productivity.

With a presence in over 50 global markets, we provide 24/7 technical solutions and customer support with solutions meant to satisfy every customer's requirements. Choose Smart Weigh Pack for reliable, fast, and low-cost rice packing solutions for your requirements.

Conclusion

Rice packing machines are essential for businesses that need accurate and high-quality packaging. Automatic machines help increase productivity, reduce waste, and ensure quality packaging in different shapes and sizes. Smart business owners know that choosing the right machine is key to success. They consider factors like production capacity, packaging flexibility, and maintenance needs to make the best choice.

For businesses looking for reliable and efficient rice packing solutions, Smart Weigh Pack offers advanced machines to meet industry needs. Explore the latest rice packaging technologies at Smart Weigh Pack and take your rice packaging operations to the next level.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine