Top Packing Line From Smart Weigh For Every Industry

A modern packaging line plays a very important role in today's production environments. Fast, accurate and reliable systems are needed by the manufacturers in the food, beverage, pet food, hardware and ready-meal industries to meet the increasing demand. Smart Weigh has established a complete range of solutions that integrate accuracy in weighing with customizable packaging modes.

Such systems assist companies to enhance production, stabilize quality and lower the cost of labor. In this guide, we will examine the best packaging lines at Smart Weigh and how each line will be applicable in various industries. Read on to learn more.

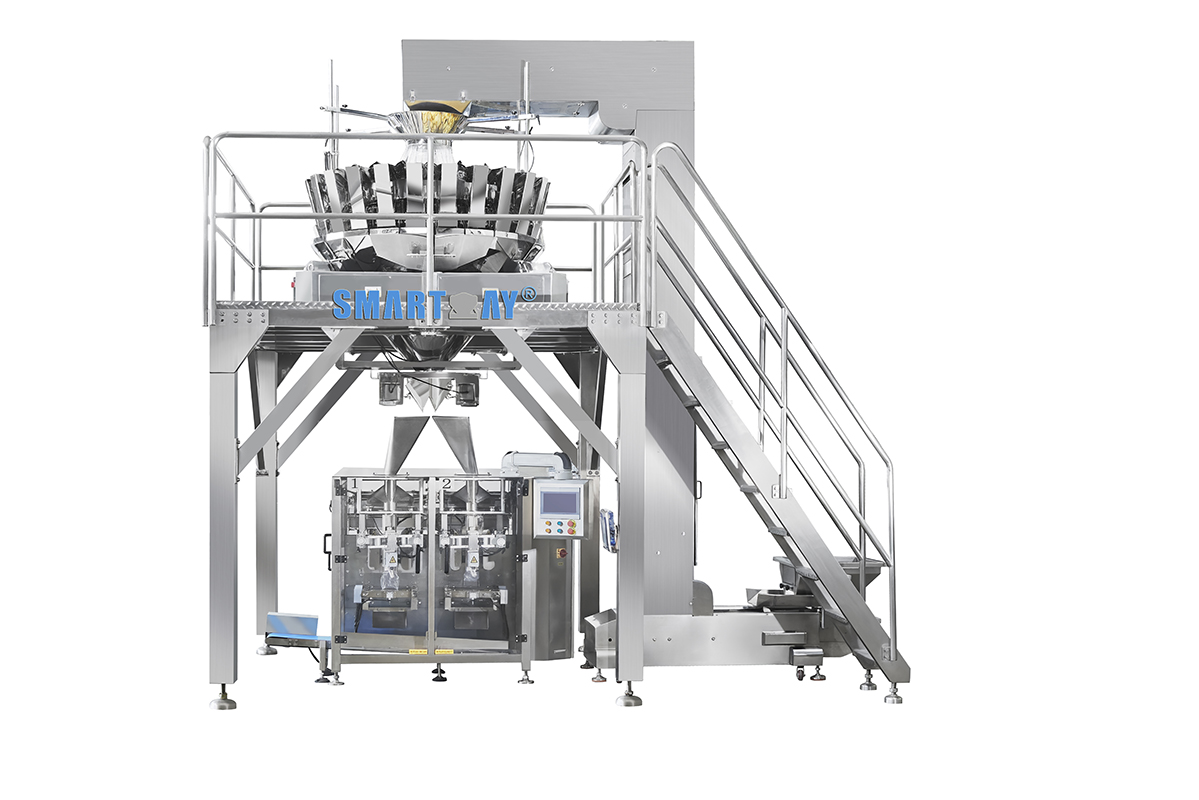

1. Multihead Weigher Vertical Packing Machine Line

Smart Weigh starts its system lineup with a vertical packing solution engineered for brands that depend on fast, consistent, and reliable production performance.

▶Structural Features

This is a multihead weigher and vertical form fill seal system that forms a continuous workflow in a seamless and efficient flow. The multihead weigher is very precise in product measurements and the vertical machine cuts bags out of roll film and seals them at high speed.

The equipment is mounted on a sturdy frame, supported by stainless-steel contact surfaces that ensure hygiene. The interface is simple to operate and the operators can change settings easily in high-productivity situations.

▶Advantages

Vertical system is very fast and accurate; hence, it is suitable for manufacturers who want to scale their operations. Since the dosing is controlled by the weigher each bag contains the right quantity of product. The vertical layout also helps save floor space, which is valuable for factories with limited space. This line can be integrated into a larger packing line, improving overall product flow.

▶Application Areas

This solution works well for:

● Snacks

● Nuts

● Dried fruits

● Frozen food

● Candies

These products benefit from accurate weighing and clean sealing, both of which are essential for quality and shelf life.

2. Multihead Weigher Pouch Packing Machine Line

Alongside vertical systems, Smart Weigh also offers a pouch-based line designed for products that require premium packaging and enhanced shelf appeal.

◆Structural Features

The pouch packing line uses pre-made bags rather than roll film. A multihead weigher measures the product, and a pouch machine holds, opens, fills, and seals each bag. The system includes automatic bag feeding, sealing jaws, and a user-friendly touchscreen. The process reduces manual handling while keeping the operation steady and repeatable.

◆Advantages

This is a flexible line that would be suited for high-value products where premium packaging is required. Ready-packaged bags enable brands to select various materials, zipper-close designs and custom designs. The accuracy of the system minimizes product wastage, which is cost-saving in the long term. Its structure also helps maintain a clean and organized packaging line, especially when switching between different product types.

◆Application Areas

This solution is commonly used for:

● Coffee

● Spices

● Premium snacks

● Pet food

Products in these categories often require better aesthetics and more durable packaging materials.

3. Multihead Weigher Jar/Can Packing Line

Smart Weigh’s experience in multi-format packaging becomes even more clear with its jar and can line, built for companies that rely on durable, long-lasting containers.

✔Structural Features

This jar packaging machine line is designed for rigid containers such as jars and cans. There are a multihead weigher, filling module, cap feeder, sealing unit and labeling station in the system. The equipment is constructed to be accurate and clean, as all containers are filled to the right level. It is made of stainless steel which facilitates the safe use of food and non-food products.

✔Advantages

Jar and can packaging are also suitable for sensitive or high-end products because they provide maximum protection and durability on the shelf. This line saves on the manpower involved in the feeding, filling, sealing and labeling of containers since it is automated. It is free-flowing in a complete packaging machine installation that saves time and increases performance.

✔Application Areas

Industries that use this line include:

● Nuts in jars

● Candy

● Hardware parts

● Dried fruit

Both food and non-food products benefit from the rigid container format, especially when appearance and durability matter.

4. Multihead Weigher Tray Packing Machine Line

To round out Smart Weigh’s offering, the tray packing category delivers specialized support for fresh foods and ready meals that demand the highest hygiene standards.

▲Structural Features

This tray packing machine line combines a multihead weigher with a tray denester and sealing unit. The dispensing of trays is automatic, with the required amount of products being loaded and the trays are closed with the film. The sealing unit also provides airtight packaging that is important in the preservation of freshness, particularly in fresh foods.

▲Advantages

The hygienic design of the system and proper weighing are used to keep the products of the right quality. It also promotes modified-atmosphere packaging whereby it prolongs the shelf life of perishable goods. It is based on automated workflow, which minimizes the use of manual labor and keeps the packing effective and well-organized.

▲Application Areas

This solution is ideal for:

● Ready meals

● Meat

● Seafood

● Vegetables

These industries require clean, consistent, and safe tray packaging to meet food safety standards.

Summary

The solutions offered by Smart Weigh can show how a properly designed packaging production line can revolutionize production. Every system, such as vertical bags, ready-made pouches, jars and cans and trays, has a particular need. Manufacturers enjoy good weighing, increased production and reduced cost of operation.

This is regardless of whether your product is snacks, coffee, hardware components or ready-to-consume foods; there is a Smart Weigh solution that fits your objectives. When you are ready to simplify your workflow, consider the entire assortment of systems offered by Smart Weigh.

Our high level of technology can be used to enhance uniformity, eliminate wastage and contribute to sustainability in the long term. Contact Smart Weigh today to find the right solution for your business.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine