Complete Guide To Milk Powder Packing Machine

Packaging is of great importance in maintaining the safety, cleanliness and preparedness of milk powder for the consumers. In food production, each process counts and packaging is one of the most important. A modern milk powder filling machine assists manufacturers to work at a faster pace even though the products remain consistent and safe.

This guide will take us through why milk powder packaging is important, the challenges involved and the types of machine used nowadays. You would also get to know about some of the main features of milk powder packing machine and how to select the appropriate system to use in your production line. Read on to learn more.

Importance of Milk Powder Packaging

Milk powder is also sensitive to moisture, air and contamination. When the product is carefully packaged, it shields the product against such risks and preserves it in the course of storing and transportation. Packages should be able to keep freshness and avoid lumping and also preserve nutritional value between factory and shelf. Proper packaging also facilitates proper control of the portion, so that the brands can offer retail sachets, large bags or cans.

Branding is also based on consistent packaging. Whether in pouches or cans, the consumer demands a clean, leak-free, and dust-free product. Good milk powder packaging machine assists the brands to offer that quality level on a regular basis.

Challenges in Milk Powder Packaging

Milk powder flows differently from granules or liquids, so packaging it brings a unique set of challenges.

One major challenge is dust. When the powder moves, fine particles rise into the air. Machines need strong dust-control features to keep the workspace clean and prevent product loss. Another challenge is achieving an accurate weight. Milk powder is lightweight but dense, so a small error in dosing can lead to a big difference in weight.

Product sticking is another concern. Powder has the ability to stick to surfaces as a result of humidity or a lack of movement and this influences the accuracy of filling. The integrity of the packaging is also of importance: the bags should close properly, preventing moisture. These issues are addressed by a reliable milk powder packaging machine that does dosing, filling and sealing of the powder with precision.

Types of Milk Powder Packing Machines

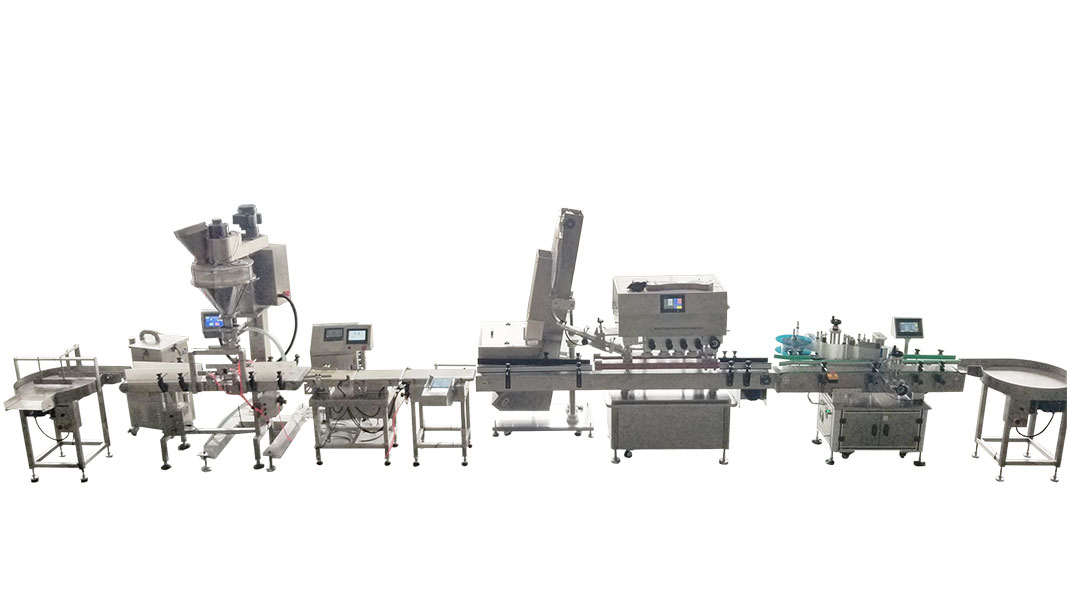

Different production needs call for different machine types. Here are three common systems used in milk powder packaging today.

✔Milk Powder Sachet Packing Machine

This machine is applied to small retail sachets, which can be a few grams to a couple of dozen grams. It consists of a screw feeder, which moves the powder in a smooth manner; an auger filler to dose the correct amount; and a small VFFS to form the sachets and seal them. It is best suited to fast-moving consumer goods, the sample pack and markets where smaller portions are typical.

✔Milk Powder Retail Bag VFFS Packing Machine

For larger retail bags, a VFFS machine forms the pouch from roll film, fills it with measured powder, and seals it securely. This system works well for 200-gram to 1-kilogram retail packaging. It offers high-speed production and strong seals that help protect against moisture.

The design supports different bag styles, making it suitable for supermarkets and export needs. A retail bag VFFS system forms the pouch, fills the powder, and seals it securely. Smart Weigh provides a reliable retail bag system built for fine powders, and you can see a similar setup in our powder VFFS packing machine.

✔Powder Can Filling, Sealing, and Labeling Machine

This system is built for canned milk powder. It fills cans with precise amounts, seals them with lids, and applies labels. It promotes the brands of infant formula, nutritional powders and high-quality milk powder. This system is also used for high-value products, where the safety and shelf life of the product are of the utmost importance, because cans provide a high level of product protection.

To understand how this type of system works in real production, Smart Weigh offers a clear example through our powder can-filling and sealing machine demonstration.

Structural Components of Milk Powder Packaging Machines

Milk powder packing systems share several core components that keep production smooth and accurate:

● Feeding system (screw feeder) to move powder steadily without clogging

● Dosing system (auger filler) for high-precision measurement

● Bag-forming or container-filling module, depending on the packaging style

● Sealing system that ensures airtight closure

● Weighing controls and sensors to maintain accuracy

● Dust-control and hygiene features that protect both product and workers

● Automation and PLC touchscreen controls for easy adjustments and monitoring

These components work together to ensure consistent quality and efficient packaging flow.

Key Characteristics of Modern Milk Powder Packing Machines

The current systems are speedy, accurate and hygienic. Machines are usually equipped with stainless steel frames and fast-cleaning parts and designed in an enclosed design preventing powder escape. Precise auger fillers are used to ensure product is of correct weight and their sealing mechanisms are strong to keep the product fresh.

The other important feature is automation. A modern milk powder food package machine can feed, weigh, fill and seal with little effort from people. This saves on labor and minimizes error. Many machines also support multiple packaging formats, switch quickly between sizes, and include intuitive touchscreen controls.

Built-in safety systems add extra protection. Features like overload alarms, door-opening stops, and dust-extraction units help create a cleaner and safer environment for workers.

How to Select the Right Machine for Your Production Line

Choosing the right machine depends on your product, production volume, and packaging format. Here are a few points to consider:

● Product type: Instant milk powder, high-fat powder, and infant formula flow differently. Your system must match the powder’s characteristics.

● Package style: Sachets, bags, and cans each require different machine types.

● Production capacity: Small manufacturers may use a compact milk powder filling machine, while large plants need high-speed VFFS systems.

● Precision requirements: Infant formula and other products require very accurate amounts of the dosage.

● Level of automation: Address the issue of complete automation or semi-automatic flexibility.

● Cleaning and maintenance: Machines that have parts that are easily accessed minimize downtime.

● Integration: Your machine must integrate into your current weighing and conveyor system.

A reliable supplier can guide you through these points and help match the machine to your long-term production goals.

Conclusion

The packaging of milk powder needs to be precise and consistent to provide high protection of the product. Through appropriate equipment, you can make it more efficient, less wasteful and produce high-quality products at all times. Both sachet systems and retail bag VFFS machines and can-filling equipment have reliable performance to meet various production applications.

When you are to improve your packaging line, explore the entire selection of systems offered by Smart Weigh or contact us to get customized guidance. We have developed high-technology solutions that can assist you in optimizing the workflow and keeping up with the current industry standards. Contact us today.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine