Why Is a Fresh Produce Packaging Machine Recommended?

1. Overview of Machines Packaging

Indigenous hand packaging processes frequently fail to fulfill the new demands for speed and homogeneity. Handling products by hand increases the danger of contamination while also lacking the uniformity required in today's distribution networks. To address these concerns, automated fresh produce packaging machines have altered the business by streamlining the packing process. These devices are designed to accurately and precisely fill each container, hence increasing the shelf life of fresh vegetables. Automation allows businesses to better control prices and manage labor shortages by lowering their reliance on manual labor. Automated packaging systems are especially appropriate for high-volume enterprises where timely, dependable delivery of fresh items is critical to meeting consumer demands.

2. The Vital Benefits of Using Fresh Produce Packaging Machines

● Fostering Freshness And Extending The Shelf Life Of The Product

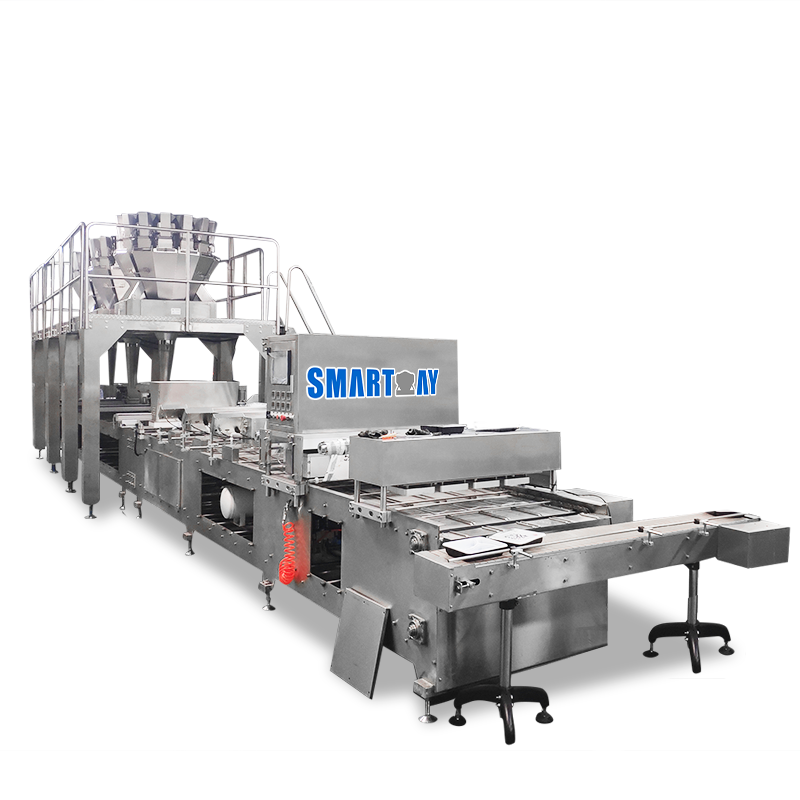

An important upside to pillow bag vertical packing machines equipped with multihead weighers is their capacity to carefully preserve the integrity and freshness of perishable foods while greatly extending shelf life. These innovative machines use precision engineering to assure consistent portioning and hermetic sealing, effectively decreasing exposure to harmful environmental components including oxygen, humidity, and UV light—key accelerants of product deterioration.

The tightly sealed pillow bags serve as an impermeable restriction, preserving the intrinsic nutrients, original tastes, and organic feel of the contents while preventing excessive moisture evaporation and external contamination. Such cutting-edge technique is particularly valuable for suppliers and exporters managing complicated, lengthy supply chains since it guarantees fresh fruit remains its original quality and market appeal even after long transit and storage times. Moreover, the use of a multihead weigher improves operational precision, reduces waste, and builds customer trust through consistent, flawlessly presented packaging.

● Reduction of Wastage

During handling and transit, fresh fruit is vulnerable to infection and damage, which can result in significant waste across the supply chain. By firmly sealing products in protective packaging that reduces movement and touch, packaging machines help to reduce these dangers. Packaging machines really help to keep the products from bruising, crushing, or deteriorating while in transit by lowering the chance of physical damage. As a result, businesses may exponentially cut down on waste, which lowers their environmental impact and saves money.

Additionally, because automated machines ensure hygiene handling and eliminates the need for human touch, contamination concerns are reduced. Hygiene is very important in the fresh produce industry, and automated packaging systems help to provide a more regulated setting, reducing the risk of contamination and enhancing final product safety.

● Improved Aesthetics and Branding

Leveraging fresh produce packaging technology also improves product branding and appeal. Produce that has been machine-packaged often seems neater and more uniform, attracting buyers and increasing brand identification. Products stand out on crowded shop shelves because automated packaging ensures consistency and makes each container seem neat and professional. On top of that, several packaging machines can print branding components directly onto the package, such as barcodes, printed images, and customizable labels. These features not only improve the product's visual appeal, but also aid in branding and traceability activities, all of which are crucial for establishing client confidence and loyalty.

3. Advanced Features of Fresh Produce Packaging Equipments

✔Automatic Weighing and Dosing Systems

Integrated weighing systems provide accurate measurement of produce, essential for meeting regulatory standards and customer expectations. Multi-head weighers and dosing units ensure each package contains the correct amount of product, enhancing reliability and trust in the brand.

✔High-Speed Operation with Precision Control

Modern vertical packaging machines are equipped with high-speed capabilities without compromising accuracy. Advanced servo motors and motion control systems allow for rapid bagging while maintaining precise control over package size and weight. This ensures consistent product quality, reduces material waste, and increases value for both businesses and customers.

✔Hygienic Design for Easy Cleaning

Adhering to strict hygiene standards is non-negotiable in fresh produce packaging. Advanced machines feature:

Stainless Steel Construction: Resistant to corrosion and easy to clean.

Tool-less Removal of Parts: Simplifies cleaning and maintenance procedures.

Washdown Capabilities: Allows for thorough cleaning without damaging the equipment.

✔User-Friendly Interfaces and Customizable Settings

The user-friendly interfaces of fresh produce packaging machines make operation easy and intuitive. Operators may effortlessly modify the machine's operations to accommodate various product varieties because of its touch screen controls and programmable settings. Businesses can vary between several packaging modes based on the needs of particular produce items thanks to customizable settings. For example, they can change the sealing strength for tougher root vegetables versus delicate lush greens.

Because of their versatility, the machines can handle a variety of produce varieties, from robust potatoes to delicate berries. Furthermore, many contemporary machines have real-time monitoring and diagnostic features that enable operators to see problems early and fix them to reduce downtime.

4. Types of Fresh Produce Packaging Solutions Available

▶Wrapping Machines

Whole vegetables including tomatoes, potatoes, and carrots are often packaged in wrapping machines. Produce is firmly wrapped in film by these machines, creating a barrier that protects it from airborne pollutants. By giving it a polished, shiny look, wrapping also enhances the visual attractiveness. The cushioning that the wrap offers is crucial for preventing bruises on fragile fruit as it is being handled.

▶Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) machines are frequently utilized to package leafy greens, salads, and other loose products. These tools were specifically envisioned to seal goods like spinach, lettuce, and mixed salad greens in flexible, upright-standing bags, retaining their freshness. MAP machines, that feature automated weighing and sealing processes, generate a regulated environment within the package, which leads to an airtight seal that reduces spoiling and increases the shelf life of the fruit.

These machinery retain beneficial freshness by governing the internal gas composition, thereby rendering them suitable for both storage and exhibition. MAP machines have become crucial for current fresh produce packaging due to their ability to extend product life while keeping flavor, texture, and nutritional content.

▶Tray Sealing Machines

Berries and sliced fruits are examples of delicate produce that work especially well with tray sealing machines. Produce is sealed in plastic or biodegradable trays by these machines, offering superior stability and protection while in transit. MAP can be used in tray sealing to lower oxygen levels, which delays spoiling and inhibits the growth of mold. Because it is simple to open and provides clients with a convenient, ready-to-use choice, tray packaging is also consumer-friendly.

5. Impact on the Supply Chain and Retailers

The supply chain is greatly impacted by fresh produce packaging equipment, which boost output from the farm to the store shelf. Packaging machines make the process faster, cleaner, and more dependable while ensuring that produce is delivered to clients in the best possible condition. By reducing spoilage and waste during transportation, these devices contribute to the development of more sustainable supply chains, which saves resources and money.

Because fewer products are returned because they are contaminated or deteriorate, retailers profit from the higher quality of produce that is machine-packaged. Retailers get a competitive edge as a result of being able to provide their consumers fresh, appealing products, which lowers the overall shrinkage rate. Retailers can also provide goods that last longer, which will increase customer loyalty and pleasure.

6. Conclusion

Companies that want to increase the quality, safety, and aesthetic appeal of their products must invest in fresh produce packaging equipments. These devices improve consistency, lower labor costs, and aid in branding initiatives by automating the packaging process. While cutting-edge methods like wrapping, vertical bagging, and tray sealing cater to the particular requirements of different types of fruit, sophisticated features like MAP, vacuum sealing, and adjustable settings guarantee that produce maintains its freshness and appeal throughout the supply chain. Fresh produce packaging machines provide an effective, economical, and environmentally responsible alternative for companies looking to satisfy the growing customer demand for fresh produce while reducing waste.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine