How about production technology for automatic weighing and packing machine in Smartweigh Pack?1

Smart Weigh Packaging Machinery Co., Ltd's production technology ranks top in the automatic weighing and packing machine industry. Since founded, we have employed professional engineers to be engaged in the exquisite production. Leveraging on our rich industry experience, this product made by us enjoys high reliability.

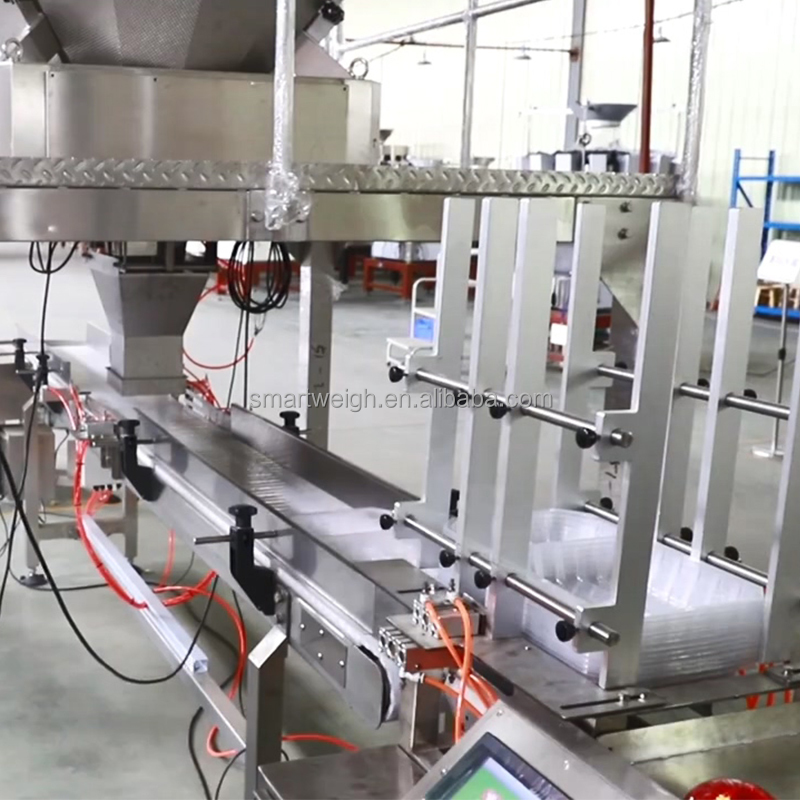

Smartweigh Pack has successfully won the sealing machines market attention. meat packing ine is one of Smartweigh Pack's multiple product series. In order to be more competitive, our automatic filling line are all designed to be unique. The latest technology is applied in the production of the smart Weigh packing machine. The product is examined by undergoing detailed tests to guarantee quality and functionality. Smart Weigh sealing machine is compatible with all standard filling equipment for powder products.

We are dedicated to achieving product superiority and make our products enjoy larger market share in different application fields. First and foremost, we will work hard to improve product quality by making use of various means.

The qualification of the manufacturer. It includes the awareness of the company、the ability of researching and developing、customer quantities and certificates.

The weighing range of multi-head weigher packing machine. There are 1~100 grams, 10~1000 grams, 100~5000 grams, 100~10000grams, the weighing accuracy depends on the weigher weight range. If you choose 100-5000 grams range to weigh 200 grams’ products, the accuracy will be bigger. But you need to choose the weigher packing machine on the basis of the product volume.

The speed of the packing machine. The speed is inversely correlated with its accuracy. The higher speed is; the worse the accuracy is. For semi-automatic weighing packing machine, it would be better to take a worker’s capacity into consideration. It’s the best choice for getting a packing machine solution from Smart Weigh Packaging Machinery, you will get a suitable and accurate quotation with electrical configuration.

The complexity of operating the machine. The operation should be an important point when selecting the multihead weigher packing machine supplier. The worker can operate and maintain it easily in daily production, save more time.

The after-sales service. It includes machine installation, machine debugging, training, maintenance and etc. Smart Weigh Packaging Machinery has a complete after-sales and before-sales service.

Other conditions include but not limited to machine appearance, the value of money, free spare parts, transportation, delivery, payment terms and etc.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425