How to automatically package the prepared dishes into the tray?

With the accelerated pace of life, consumers increasingly like to buy prepared dishes to shorten the cooking time. Many restaurants also choose ready-to-eat food, which can ensure the stability of the quality and taste of dishes. Today, Smart Weigh recommends a Vacuum Tray Forming Machines, which can realize automatic weighing and packaging of RTE food.

Automated thermoforming packaging production: airline meals, high-speed rail lunch, prepared dishes, ready-to-eat food, fast food, etc.

Weighing and packaging of lunch boxes: There are various types of vegetables and irregular shapes, such as: diced radish, cucumber slices, potato slices, etc., the weighing accuracy is difficult to control.

We recommend different types of weighers for materials of different shapes and sizes.

ü For products with similar shapes and sizes, they can be weighed on the same weigher, such as shredded radish and shredded onion, and screw multi-head weighers can be selected; For large pieces of materials such as spare ribs and wax gourd, you can choose a multi-head weigher with vibrating plate feeding;

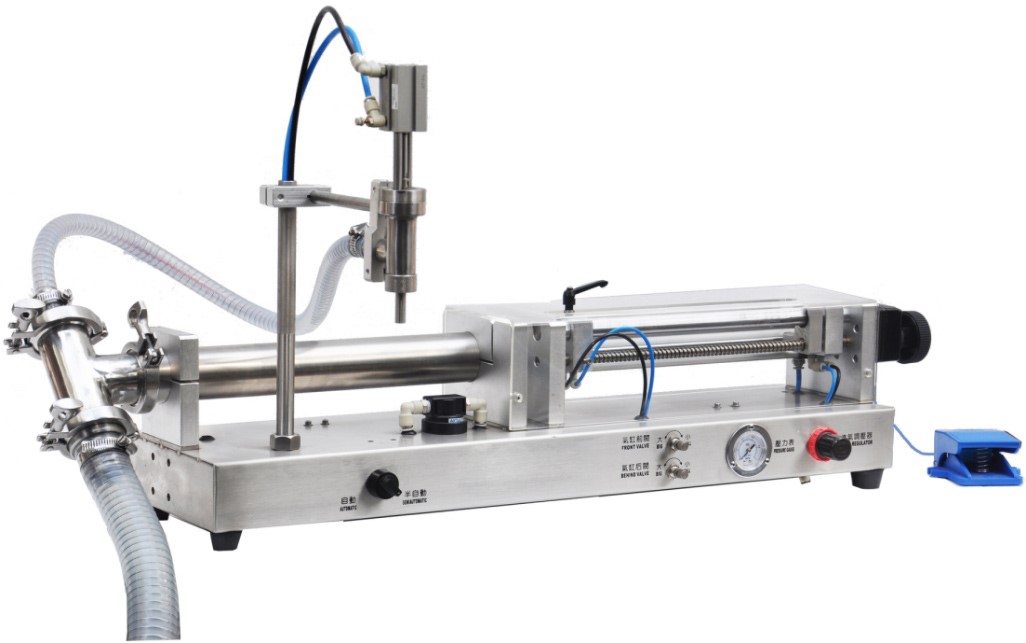

ü If you need chopped green onion, sauce and other accessories, we can provide measuring cups or liquid pumps to meet the needs.

ü Committed to the weighing of multiple products with the least number of machines.

Cup filler

Cup filler  Liquid pump

Liquid pump

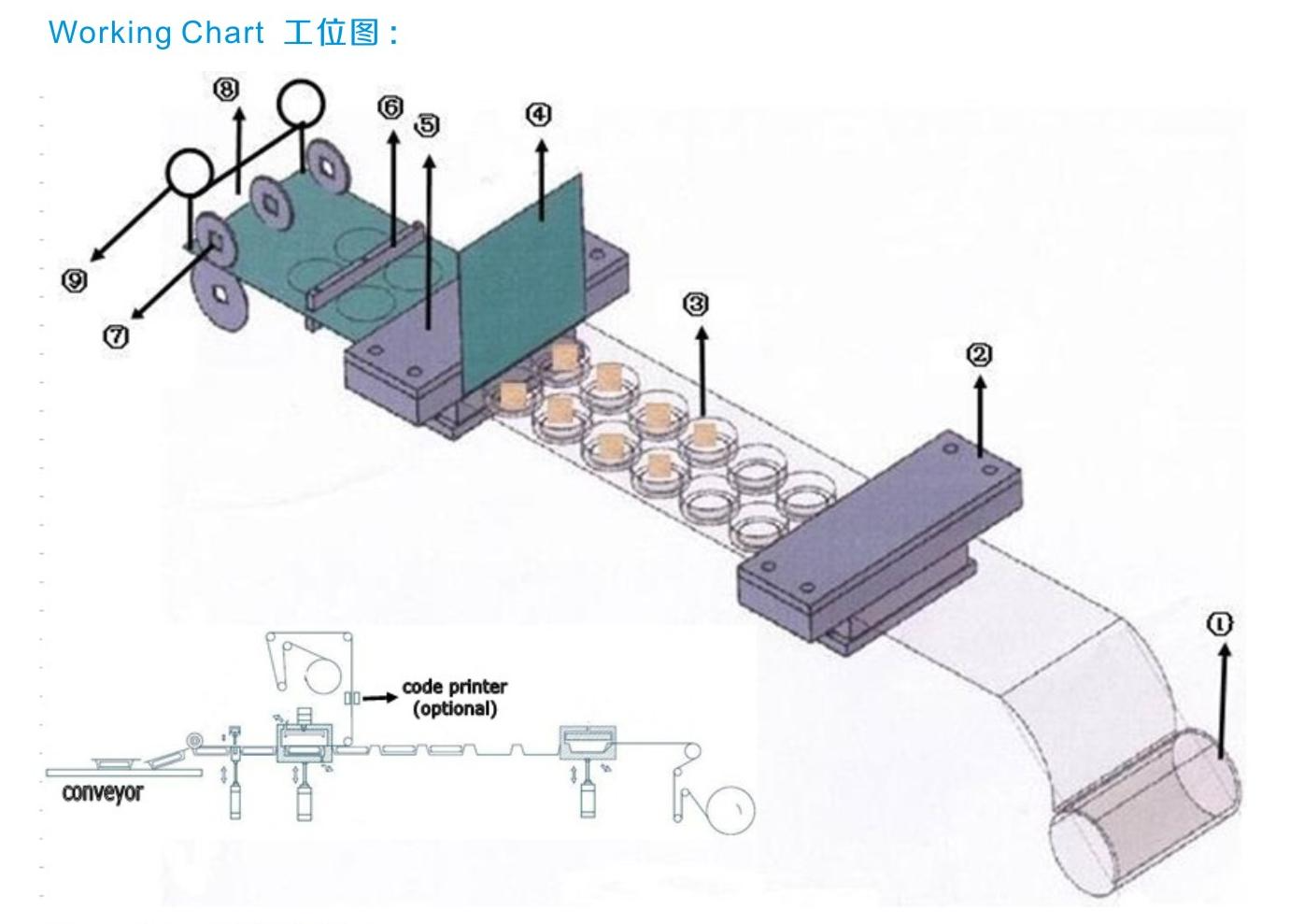

1. Lower film loading 2.Thermal forming 3.Filling

4. Upper film covering 5.Sealing 6.Punch cutting

7. Longitudinal cutting 8.Conveying 9.Waste disposal

Model | ATS-4R-V |

Voltage | 380v 50hz |

Power | 10.5 kw |

Speed | 500-600 tray/hour |

Container size | Customized according to the sample tray |

Sealing temperature | 0-250℃ |

Intake pressure | 0.6-0.8Mpa |

Air consumption | 2-1.4 m3/min |

Gross weight | 1500kg |

Machine dimensions | 4250*1250*1950mm |

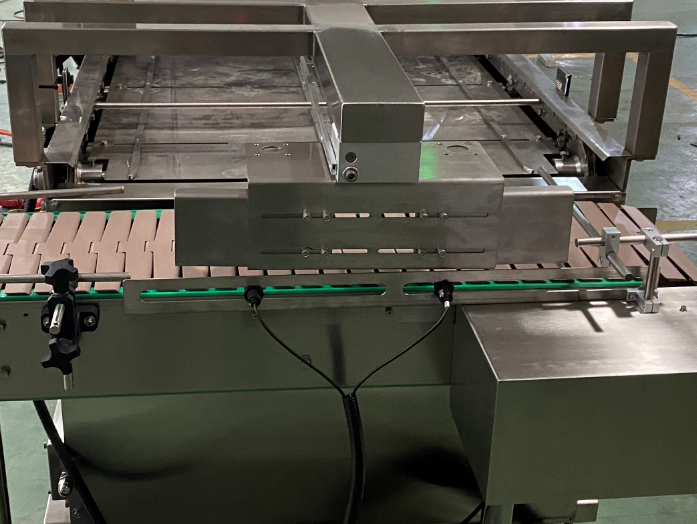

l Automatic loading of empty trays, detection of empty trays, quantitative filling, automatic film pulling, film cutting and heat sealing, recycling of waste film, automatic ejection of finished products, and processing of 1000-1500 trays per hour.

l The whole machine is made of 304 stainless steel and anodized aluminum, which ensures that it can operate in the harsh food factory environment such as humidity, steam, oil, acid, salt, etc., and its body can be washed clean with water.

l Driving system: Servo motor with gear box, the tray mold runs step by step, which can move the filled tray very quickly, avoiding material splashing, because the servo motor can start and stop smoothly, and the positioning accuracy is high.

l Empty tray feeding function: The spiral separation and pressurization technology is adopted to avoid the damage and deformation of the tray, and it is equipped with a vacuum suction cup to guide the tray to enter the mold accurately.

l Empty disk detection function: use photoelectric sensor or optical fiber sensor to detect whether the mold has empty disk, avoid wrong filling, sealing and capping when the mold has no disk, and reduce product waste and machine cleaning time.

l Quantitative filling function: The multi-head intelligent combined weighing and filling system is used to perform high-precision weighing and quantitative filling of solid materials of various shapes. The adjustment is convenient and quick, and the gram weight error is small. Servo-driven distributor, accurate positioning, small repeated position error, stable operation.

l Vacuum gas flushing system: It is composed of vacuum pump, vacuum valve, air valve, air release valve, pressure regulating valve, pressure sensor, vacuum chamber, etc., which can pump and inject air to prolong the shelf life.

l Roll film sealing and cutting function: The system consists of automatic film pulling, printing film positioning, waste film collection and constant temperature sealing and cutting system. The sealing and cutting system runs fast and has accurate positioning. Thermostatic sealing and cutting system adopts Omron PID temperature controller and sensor for high-quality heat sealing.

l Unloading system: It is composed of pallet lifting and pulling system, ejecting conveyor, packed pallets are lifted and pushed to the conveyor quickly and stably.

l Pneumatic system: It consists of valves, air filters, instruments, pressure sensors, solenoid valves, cylinders, mufflers, etc.

As a manufacturer of weighing and packaging machines, Guangdong Smart Weigh pack can customize suitable weighing and packaging schemes for customers. At present, it has installed more than 1000 systems in more than 50 countries.

The products provided by Smart Weigh include: multihead weigher, salad weigher, nut mixture weigher, sprinkled vegetable weigher, meat weigher, CCW scale, data weigher, vertical packaging machine, premade bag packing machine, drive fruit packing, frozen food packing, nuts packing, labeling, check weigher, metal detection, verification and robotic case packing line solutions. Our team has a unique combination of innovative technology, foreign language communication ability, rich project management experience and 24-hour global support to ensure that customers can obtain higher accuracy/efficiency/space saving weighing and packing solution at the lowest cost.

How to meet customer needs?

We will provide customized machines according to customers' specific production conditions, weighing and packaging needs.

Smart Weigh provides 24-hour online service to quickly answer customers' questions.

How to pay?

You can choose bank account direct telegraphic transfer or sight letter of credit.

How to ensure the quality of the machine?

Smart Weigh will send pictures and videos of the machine to customers before delivery, and even welcome customers to come to the workshop to learn about the operation of the machine.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine