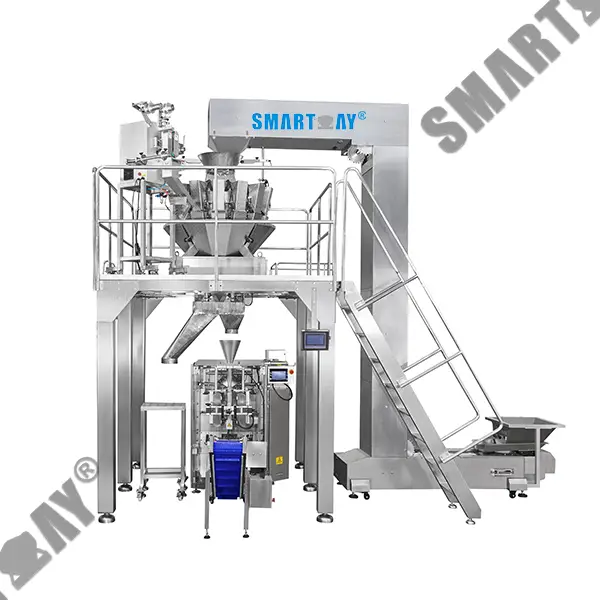

Gummy Jellies Candy Packaging Machine Line

This automatic jellies and gummy packaging machine handles everything from classic gummy bears, gummy worms to trendy CBD jellies, wrapping up to 40-120 packages every minute without breaking a sweat. What really sets it apart is how it actually works in real production environments – not just in perfect lab conditions.

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

More Choices

Looking to upgrade your candy packaging operation? Our Gummy & Jellies Candy Packaging Machine isn't just another piece of equipment – it's the solution many confectionery businesses have been waiting for. We've designed this machine after listening to countless manufacturers who were frustrated with slow, unreliable packaging that couldn't keep up with demand.

This automatic packaging equipment handles everything from classic gummy bears, gummy worms to trendy CBD jellies, wrapping up to 40-120 packages every minute without breaking a sweat. What really sets it apart is how it actually works in real production environments – not just in perfect lab conditions.

We built this candy packaging machine with food-grade materials because, let's face it, anything less isn't worth your time or money. It meets all the regulatory requirements you need (FDA, CE certification, the works), but more importantly, it's designed by people who understand that downtime costs you money and frustrated operators make everyone's life harder.

Whether you're running a family candy business that's outgrown manual packaging or you're a contract manufacturer juggling multiple brands, this machine adapts to what you actually need – not what some engineer thinks you should want.

| Weight Range | 10–1000 grams |

| Packaging Speed | 10-60 packs/min, 60-80 packs/min, 80-120 packs/min (depends on actual machine model) |

| Bag Style | Pillow bag, gusset bag |

| Bag Size | Width: 80-250 mm; Length: 160–400 mm |

| Film Materials | Compatible with PE, PP, PET, laminated films, foil |

| Control System | Modular control system for multihead weigher; PLC control for vertical packing machine |

| Air Consumption | 0.6 MPa, 0.36 m³/min |

| Power Supply | 220V, 50/60Hz, single phase |

The Smart Weigh Jelly & Gummy Weighing Packaging Machine Line is purpose-built for the confectionery industry, making it the go-to solution for packaging:

✅ From Standard to Ultra-High Speed Production Capability

Achieve maximum productivity with packaging speeds up to 120 packages per minute, significantly outperforming traditional equipment. The advanced servo-driven system ensures smooth, consistent operation even at peak speeds, allowing you to meet demanding production schedules while maintaining superior pack quality and reducing per-unit costs.

✅ Precision Weight Control & Dosing System

Integrated Smart Weigh's anti-stick surface multi-head weigher delivers exceptional accuracy within ±1.5g tolerance, ensuring consistent product portions and regulatory compliance. The intelligent dosing system automatically adjusts for product variations, minimizing giveaway while maintaining customer satisfaction and protecting your profit margins.

✅ Quick Changeover

Seamlessly switch between different pack sizes and product types in just 15 minutes using our tool-free adjustment system. Handle everything from small 5g gummy packs to large 100g family sizes, accommodating pillow packs and gusset bags.

✅ Food-Grade Hygienic Design

Constructed entirely from premium stainless steel 304 with sanitary finishes, ensuring complete compliance with FDA, cGMP, and HACCP requirements. The machine features easy-clean surfaces, removable components, and washdown capability, enabling thorough sanitization between product runs and maintaining the highest food safety standards.

✅ Advanced Sealing Technology

Proprietary heat sealing system creates tamper-evident, airtight packages with great seal integrity success rate. Multiple sealing parameters such as sealing temperature and sealing time can be set on user-friendly color touch screen.

Q1: Can this handle sticky gummy products without jamming?

A1: Yes. The Smart Weigh multihead weigher uses anti-stick surface technology and controlled vibration specifically designed for tacky gummies and jellies. It maintains ±1.5g accuracy even with sticky products.

Q2: What's the real production speed?

A2: 45-120 packages per minute depending on machine model and product size. Please tell Smart Weigh team your product details, we will offer you different packaging solutions.

Q3: How much space does it need?

A3: Machine footprint: 2 x 5 meters, height 4 meters needed. Requires 220V, single phase power and compressed air.

Q4: Can this integrate with my existing packaging line?

A4: Usually yes. The system outputs to standard conveyors and can integrate with most bag sealers, case packers, and palletizing equipment. We provide integration consultation during the planning phase to ensure smooth connectivity.

Q5: Can this machine weigh and mix different flavors jelly?

A5: The standard multihead weigher only can weigh 1 type of jelly, if you have mixture requirements, our mixture multihead weigher is recommended.

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Quick Link

Packing Machine