Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

Vertical Form Fill Seal Line Automatic Coffee Bean Packaging Machine

Multihead weigher VFFS machine for whole coffee bean or ground coffee packaging offers accuracy, efficiency, flexibility, and quality assurance, making it a valuable asset for coffee producers looking to streamline their packaging processes. It is a sophisticated piece of equipment used in the food and coffee industry.

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

More Choices

Vertical Form Fill Seal Line Automatic Coffee Bean Packaging Machines

An integrated multihead weigher + VFFS coffee line for whole beans or ground coffee. Delivers stable weights, high throughput (20–100 bags/min), nitrogen for freshness, and retail-ready bag styles (pillow, gusset, quad/four-side). Compatible with laminated and mono-PE recyclable films. Ideal for roasters and co-packers upgrading speed, accuracy, and shelf life.

Who it's for: specialty roasters, private-label co-packers, and producers running 100–1000 g SKUs with clear ROI targets on labor, giveaway, and shelf-life.

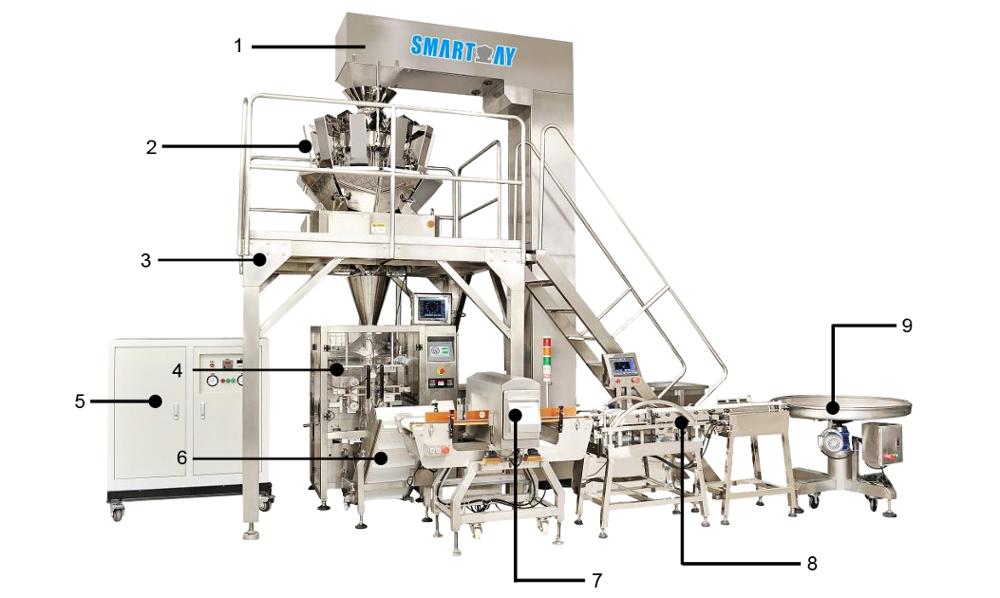

How the line works (process & modules)

1. Bucket Conveyor — Automated feeding to the scale, consistent head pressure.

2. Multihead Weigher — Fast, gentle dosing for whole beans; recipe-based accuracy.

3. Working Platform — Safe access and maintenance for the scale.

4. Vertical Packing Machine — Forms, fills, and seals pillow/gusset/quad bags; optional valve inserter.

5. Nitrogen Generator — Lowers residual O₂, preserves aroma and flavor.

6. Output Conveyor — Transfers finished bags to QA or case packing.

7. Metal Detector (optional) — Rejects metal-contaminated packs.

8. Checkweigher (optional) — Verifies net weight, auto-rejects out-of-tolerance.

9. Rotary Collection Table (optional) — Buffers good packs for manual packing.

Options to consider: dust extraction (for ground coffee), printer/labeler, leak/O₂ spot tester, valve applicator, infeed product aligners.

Applications

Specification

Model | SW-PL1 |

Weighing Range | 10-5000 grams |

Bag Size | 120-400mm(L) ; 120-400mm(W) |

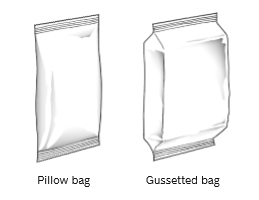

Bag Style | Pillow Bag; Gusset Bag; Four side seal |

Bag Material | Laminated film; Mono PE film |

Film Thickness | 0.04-0.09mm |

Speed | 20-100 bags/min |

Accuracy | + 0.1-1.5 grams |

Weigh Bucket | 1.6L or 2.5L |

Control Penal | 7" or 10.4" Touch Screen |

Air Consumption | 0.8Mps 0.4m3/min |

Power Supply | 220V/50HZ or 60HZ; 18A; 3500W |

Driving System | Stepper Motor for scale; Servo Motor for bagging |

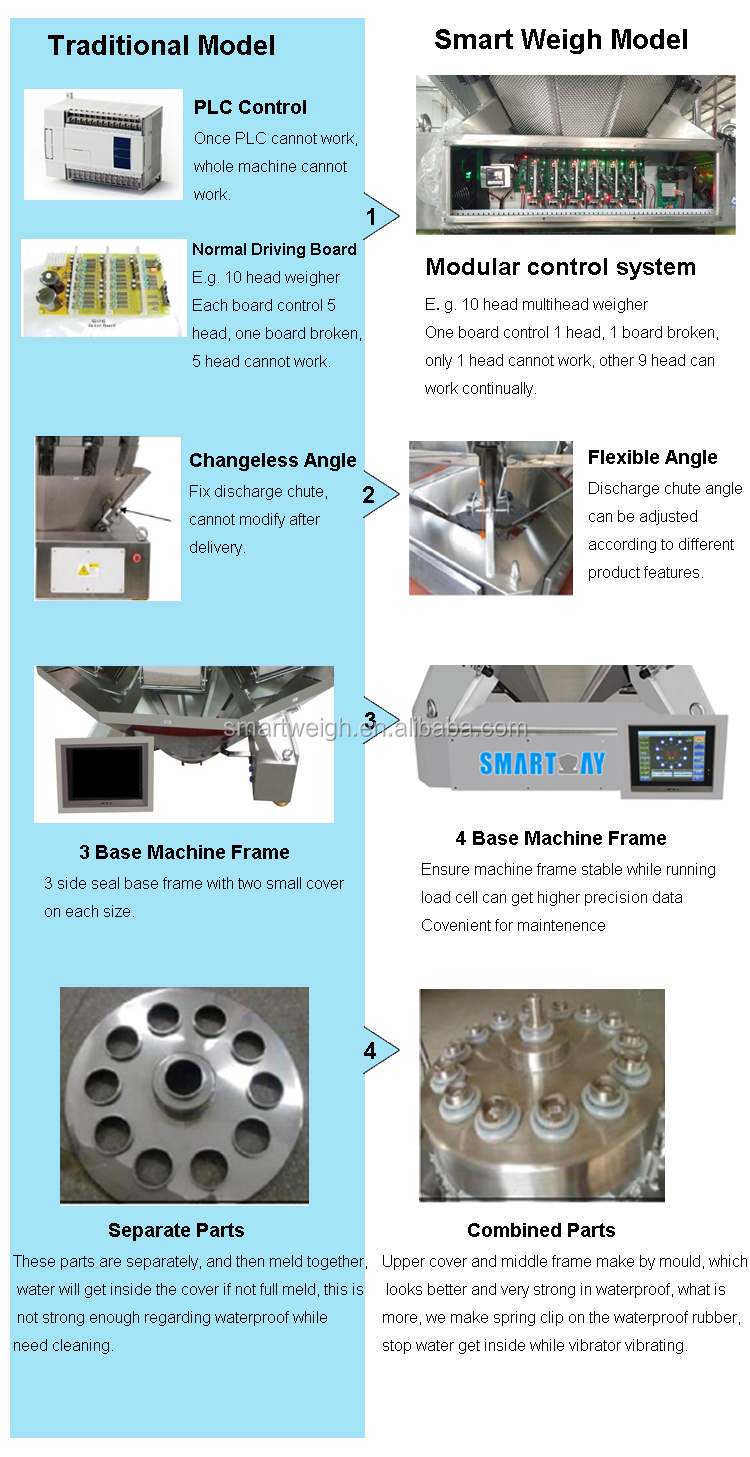

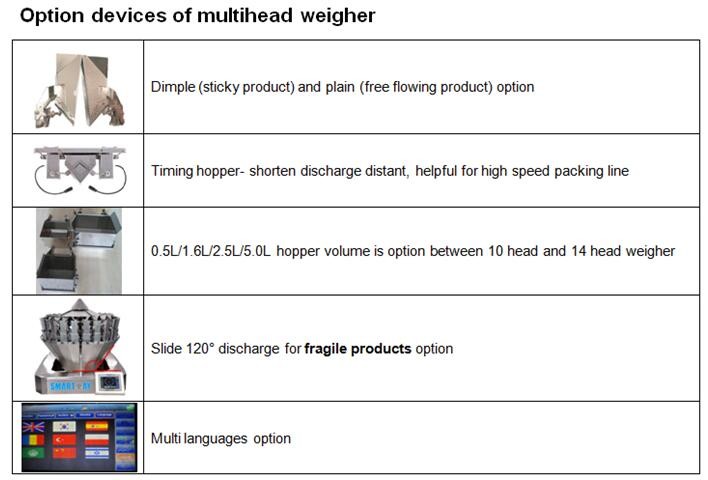

Multihead Weigher

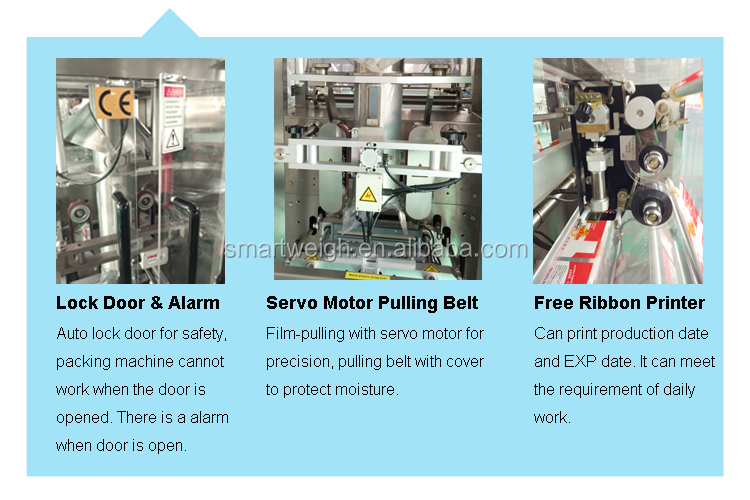

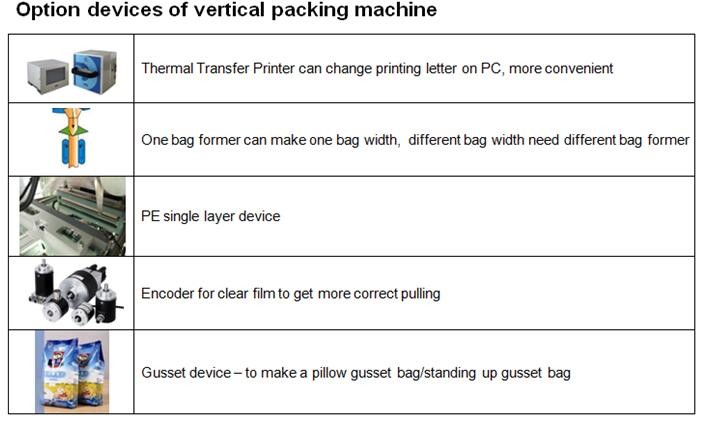

Vertical Packing Machine

FAQs

1) Can this line pack both beans and ground coffee?

Yes. For beans, use the multihead weigher; for ground coffee, add an auger filler module or a dedicated lane. Recipes and tooling enable quick changeovers.

2) Do I need nitrogen and a degassing valve?

For freshly roasted beans and long distribution, we recommend the one-way valve vents CO₂ without letting oxygen in.

3) Can it run recyclable mono-PE films?

Yes—after sealing window validation. Expect minor parameter changes (jaw temp/dwell) versus standard laminates.

4) What speed should I expect on 250–500 g bags?

Typical ranges are 40–90 bags/min depending on film, gas flush, and valve insertion. We’ll simulate your SKUs during FAT.

5) How accurate is the system in real production?

±0.1–1.5 g is typical; actual performance depends on product flow, target weight, film, and line settings. A checkweigher keeps compliance tight.

Turnkey Solutions Experience

Exhibition

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425