Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

How do multihead weigher work?

How do multihead weigher work?

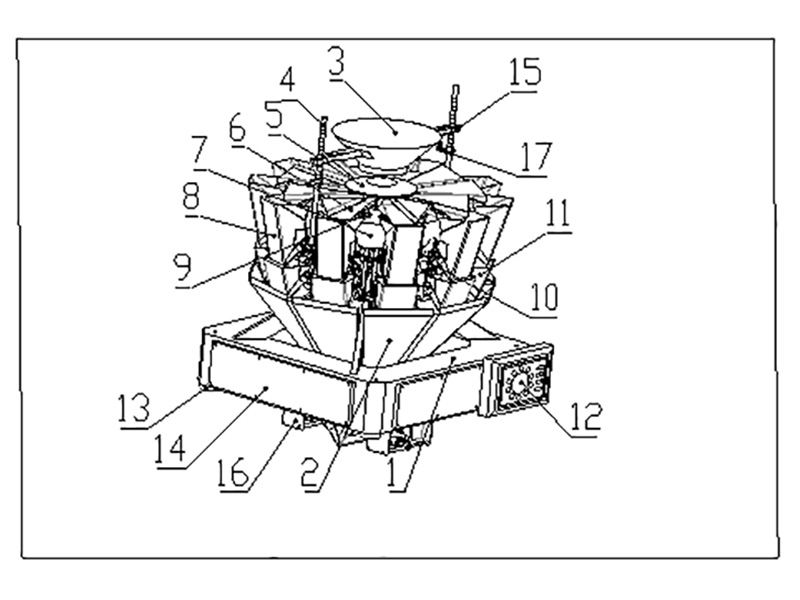

Part No. | Description | Part No. | Description |

1 | Machine Frame | 10 | Actuator |

2 | Discharge Chute | 11 | Weigh Hopper |

3 | In-feed Funnel | 12 | Touch Screen |

4 | Supporting Post | 13 | Plastic Screw |

5 | Top Cone | 14 | Base Cover |

6 | Linear Feeder Pan | 15 | Sensor Clamp |

7 | Upper Cover | 16 | Timing Hopper |

8 | Feed Hopper | 17 | Photo Sensor |

9 | Linear Vibrator |

|

|

The weigh hoppers connect with load cell, products will be weighed in weigh hoppers. There are 10 weigh hoppers in 10 head multihead weigher. After hoppers weighed, load cells will send each weight to CPU, CPU will calculate the most accurate combination weight by 3-5 hoppers from 10 hoppers, the selected hopper will open, other hoppers with products will keep wait for next combination calculation, empty hopper will be feed products from its feed hopper.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425