Introduction To The Stability And Accuracy Of The Automatic Control System Of The Automatic Vertical Packaging Machine

There are even more types of packaging machines as society and business progress. Fully automatic VFFS packing machines are commonly employed in the food, chemical, pharmaceutical, and light industries. Intelligent packaging equipment has steadily arisen in front of us to execute numerous procedures at once. Then we'll look at the automatic control system of the automatic VFFS packing machine's stability and precision.

The Automatic Control System Of The Automatic Packing Machine's Stability:

Because of the inertia of the fully automatic packing machine's automatic control system, inappropriate allocation of the system's different parameters would cause the system to oscillate and lose its operating capacity. Stability refers to the ability of the dynamic process to restore equilibrium following oscillations.

The output will diverge from the initial stable value when the interruption or the set value changes. The automatic VFFS packing machine automatically adjusts the system's internal adjustment function based on the feedback function.

Over time, the system converges and eventually recovers to its former stability. To stabilize the value or follow the specified value. The system cannot function if it diverges and becomes unstable for whatever reason. The first criterion for system functioning is stability.

The Precision Of The Automatic Packing Machine's Control System:

Accuracy is often referred to as static accuracy. It is the difference between the output of the automated assembly machine's automatic control system and the provided value after the adjustment process has been completed. It reflects the system's correctness and is a key indicator for measuring its performance.

Some systems, such as position control, require great precision. Furthermore, conventional ambient temperature and synchronous motor systems can be accurate within 1% of the provided value. Various systems have varying requirements for stability, precision, and speed because of the different particular characteristics of the controlled objects.

The servo system, for example, has high criteria for speed, but the speed control system has rigorous standards for stability. The system's performance is mutually limited by stability, precision, and speed. A system with quick speed and strong performance may be susceptible to oscillation; a system with high stability may have a slower adjustment procedure and lesser accuracy.

Significant findings should be carried out in accordance with the system's set targets, with the primary contradictions comprehended and others taken into account.

Accuracy Of The Automatic Vertical Packing Machine's Control System

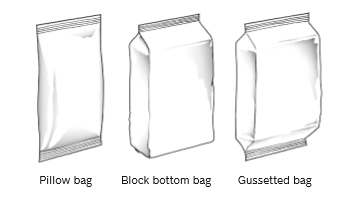

Vertical packing machines are primarily used for packaging liquids, grains, granules, and other foods or pharmaceuticals that the bags cannot be packaged horizontally. The packing method is mainly classified into two types: intermittent and continuous sealing. Bag styles are classified as three-side seals, four-side seals, pillow bag and gusset bag.

At the same time, while packaging various materials, different feeding methods, such as screw scales, combination scales, measuring cups, and so on, are required.

Typically, an automated vertical packaging machine is based on a horizontal automatic packaging machine. A new type of automatic zipper freestanding vertical bag packaging machine was developed with a unique packaging idea, advanced technology, and multiple configurations of the cutter. Liquid, powders, grains, and bulk items, such as self-supporting packages, may all be produced by this machine.

It is widely utilized in various sectors, including food, hardware, electronics, medicines, cosmetics, fertilizers, agriculture, etc. Afterwards, how do we recognize it and its cons? Let's have a peek.

1. Automatic packaging machine appearance: the appearance is aesthetically pleasing, reasonable, and consistent with vacuum packaging machine design standards; additionally, the corners of good automatic packaging machines are relatively smooth, not rough.

Automatic packaging machine materials: stainless steel structure automated assembly machines can have a specific thickness. Furthermore, carbon steel materials packaging machine is another choice if the budget is limited.

1. Automatic VFFS packing machine components: better selection of automatic packaging machine components, components with a typically low bad life, usage of comfort, and so on.

2. Automated VFFS packing machine manufacturers' sales: In addition to regular manufacturers giving consumers certified products, products for maintenance and servicing are more convenient, making good product manufacturers better.

Where To Buy From?

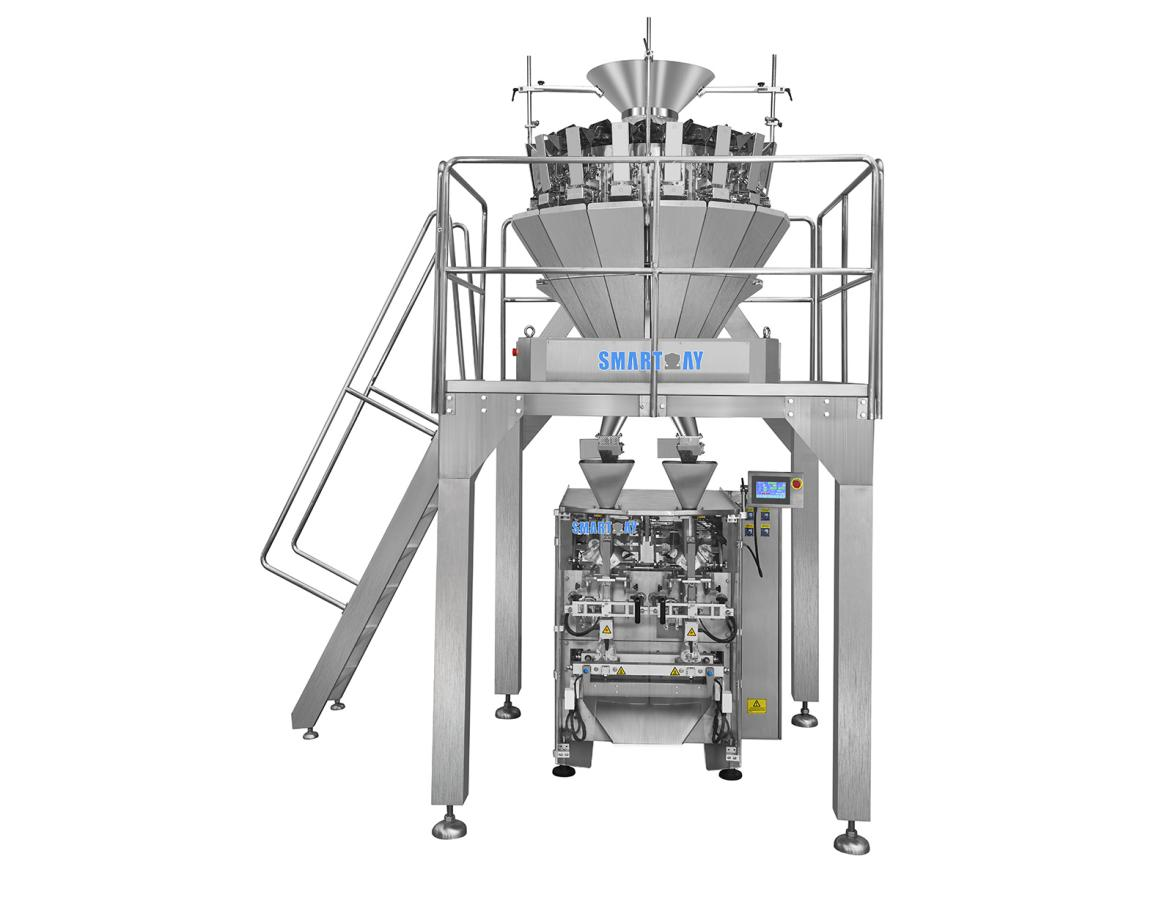

We can provide you with a high-profile packing machine. For film-based packaging such as sachets, pillow bags, gusset bags, quad-sealed bags, prefabricated bags, stand-up pouches, and another film-based packaging, Smart Weigh manufactures vertical packaging machines and prefabricated bag packing equipment.

Guangdong Smart Weigh Packaging Machinery Co., Ltd. is a well-known multihead weigher packing machine and packaging machine manufacturer that specializes in the design, manufacture, and installation of multicoloured weighers, linear weighers, check multihead weigher packing machines, metal detectors, and complete weighing and packing line solutions to meet a wide range of customized needs.

Author: Smartweigh–Multihead Weigher

Author: Smartweigh–Multihead Weigher Manufacturers

Author: Smartweigh–Linear Weigher

Author: Smartweigh–Linear Weigher Packing Machine

Author: Smartweigh–Multihead Weigher Packing Machine

Author: Smartweigh–Tray Denester

Author: Smartweigh–Clamshell Packing Machine

Author: Smartweigh–Combination Weigher

Author: Smartweigh–Doypack Packing Machine

Author: Smartweigh–Premade Bag Packing Machine

Author: Smartweigh–Rotary Packing Machine

Author: Smartweigh–Vertical Packaging Machine

Author: Smartweigh–VFFS Packing Machine

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine