Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

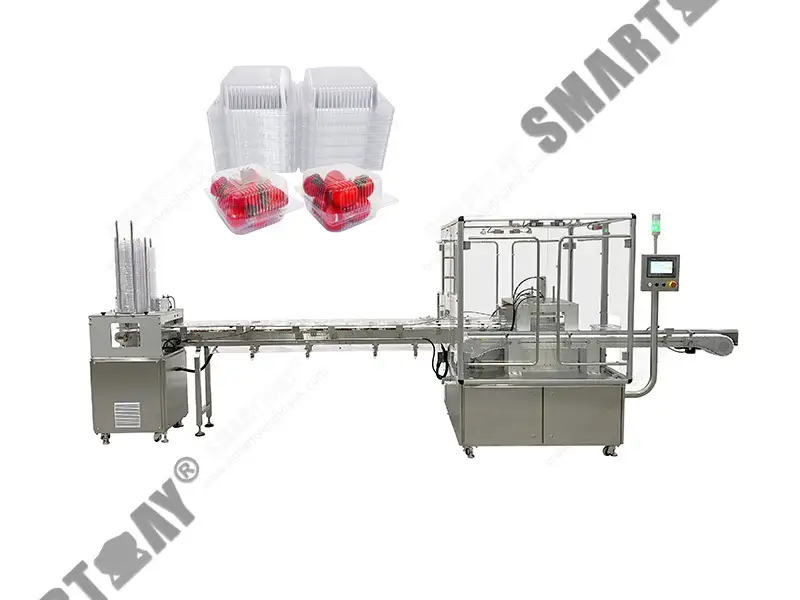

New Design Clamshell Packaging Machine

Smart Weigh clamshell packaging machine, the design meet USA standard. Can works with weigher for fully automatic packaging process from drop clamshell, weighing, filling, closing and sealing.

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

More Choices

| Model | SW-T1 |

| Clamshell Size | L=100-280, W=85-245, H=10-75 mm (can be customized) |

| Speed | 30-50 trays/mi |

| Tray Shape | Square, round type |

| Tray Material | Plastic |

| Control Panel | 7" touch screen |

| Power | 220V, 50HZ or 60HZ |

The system is described as a turnkey solution, comprising several integrated machines:

● Clamshell Feeder: Automatically feeds clamshell containers, ensuring a continuous flow into the system.

● Multihead Weigher (Optional): A critical component for precise weighing, essential for meeting weight specifications. Multihead weighers, are known for their speed and accuracy, suitable for granular and irregular-shaped products.

● Support Platform (Optional): Provides a stable base, ensuring smooth operation of the entire line.

● Conveyor with Tray Positioning Device: Transports clamshells and stops under the filling station, weigher fills into clamshell with the weighed product, minimizing contamination risks, which is vital for food safety.

● Clamshell Closing and Sealing Machine: Closes and seals the clamshells. This ensures product integrity and freshness.

● Checkweiger (Optional): Verifies the weight post-packaging, ensuring compliance with standards, a common practice in automated lines.

● Labeling Machine with Real-Time Printing Function (Optional): Applies labels with customizable information, enhancing branding and traceability, a feature noted in automated packaging solutions.

1. The fully automatic process is a standout feature, reducing the need for manual intervention, which can lead to significant labor cost savings. The system's precision in filling and sealing ensures consistent quality, crucial for maintaining consumer satisfaction and product integrity.

2. Adjustability is another key aspect, the machine can fit various sizes of clamshell, the denesting and closing positions are able to adjust manually.

3. Can works with more automatic machines such as multihead weigher, checkweigher, metal detector and clamshell labeling machine.

Smart Weigh offers extensive technical support, including installation and maintenance training for operators. This is crucial for ensuring minimal downtime and effective use, a practice common in the industry. The content notes that technicians were present at a client's factory for installation, underscoring their commitment to service.

● Comprehensive Solutions: Covers all steps from feeding to labeling, providing a seamless process.

● Labor and Cost Savings: Automation reduces manual labor, leading to cost efficiencies.

● Customization Options: Adjustable for different needs, enhancing adaptability.

● Precision and Consistency: Ensures high-quality packing, vital for food safety and consumer trust.

● Stable Packing Speed: Reliable performance at 30-40 clamshells per minute, ensuring production timelines are met.

● Versatility: Suitable for a range of products, broadening market applicability.

● Quality Assurance: Machines undergo rigorous testing, meeting industry standards, a critical factor for regulatory compliance.

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425