Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

Rotary premade bag doypack pouch packaging machine with multihead weigher

premade bag packaging system

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

More Choices

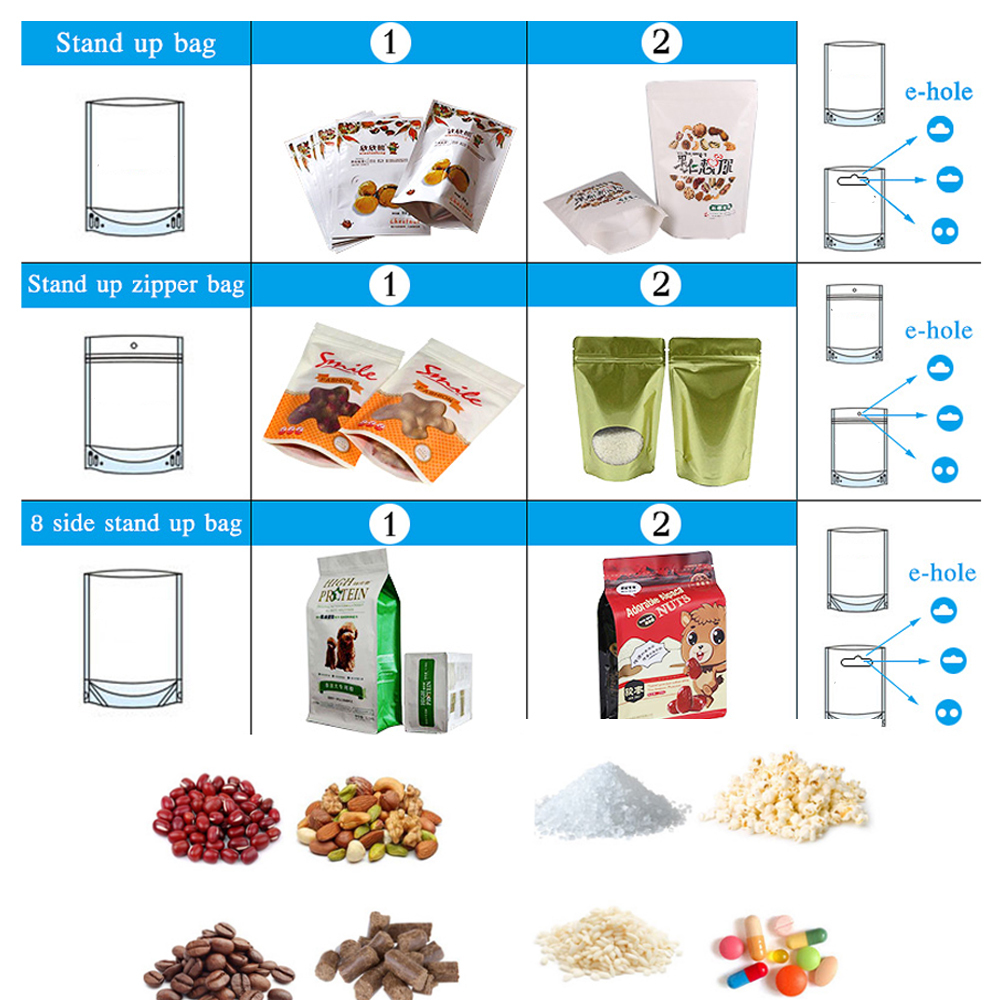

A rotary pouch packaging machine is an automatic bagging machine used for automated filling and sealing of pouches in the packaging industry. Pre made pouches are a popular packaging format due to their flexibility, efficiency, and capability to maintain product freshness. The commom pouch formats are flat pouches, stand up pouches, carry handle doypack, zipper pouches, gusset pouches, 8 side seal pouches and sprout pouches.

Rotary pouch packaging machines are used for packing various products, such as frozen foods, snack foods, meat, pet food, fresh fruits and more dry products.

※ Standard Features

◆ Enable to equip with other machines, make all process full automatic from feeding, weighing, filling, sealing to outputting;

◇ Suitable for various pre made pouch, no matter they are laminate materials, polyethylene materials or recyclable materials.

◆ Rotary packaging machines has 8 stations for one process. First station connects with pouches feeding device, automatically open premade pouches; next station is pouches printing, ribbon printer, Thermal transfer printers (TTO) or laser is available here; the next three stations are pouches opening station, fill station and sealing station. After the pouches sealing, finished pouches will be sent out.

◇ Open door alarm and stop machine running in any condition for safety regulation;

◆ 8 station holding pouches finger can be adjustable, easy operation and convenient for changing different bag size;

◇ Made of robust stainless steel frame, all parts can be taken out without tools.

※ Specification

| Model | SW-8-200 |

| Working Station | 8 |

| Speed / Production rates | 50 packs per minute |

| Pouch Size | Width 100-250 mm, length 150-350 mm |

| Pouch Material | polyethylene and laminate materials, includes recyclable packaging material |

| Power Supply | 380V, 50HZ/60HZ |

※ Packing system composition

1. Weighing Equipment: Multihead weigher, linear weigher are popular pouch filling machine for granule products, they are with modular control system, keep production efficiency; auger filler is for powder products and liquid filler is for liquid and paste.

2. Infeed Bucket Conveyor: Z-type infeed bucket conveyor, big bucket elevator, inclined conveyor.

3.Working Platform: 304SS or mild steel frame. (Color can be customized)

4. Packing machine: Vertical packing machine, four side sealing machine, rotary packing machine.

5.Take off Conveyor: 304SS frame with belt or chain plate.

※ Application

※ Product Certificate

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425