Seta makore apfuura, Smart Weigh inyanzvi yekugadzira uye zvakare mutengesi ane simba rakasimba mukugadzira, dhizaini, uye R&D. tireyi yekurongedza muchina Smart Weigh inogadzira yakazara uye mutengesi wemhando yepamusoro zvigadzirwa uye imwe-kumira sevhisi. Isu ticha, senguva dzose, tichishingaira kupa masevhisi ekukurumidza akadai. Kuti uwane rumwe ruzivo nezve tireyi yedu yekurongedzera muchina uye zvimwe zvigadzirwa, ingongotizivisa.Chikafu chakabviswa mvura nechigadzirwa ichi chine hutano hwakawanda sezvahunoita kusati kwapera mvura. Kupisa kwese kunokodzera chikafu chakawanda kunyanya chikafu chine chikafu chinonzwa kupisa.

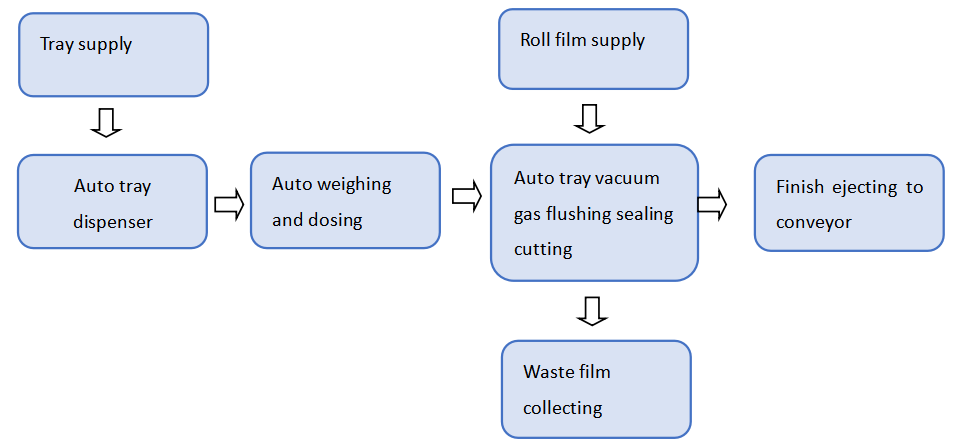

Zvakakwana otomatiki linear tray yekuzadza sealing muchina inogona kurodha matireyi asina chinhu, kuona matireyi asina chinhu, auto quantitative kuzadza chigadzirwa mutireyi, otomatiki firimu kudhonza uye kuunganidza tsvina, otomatiki. tray vacuum gasi kutsvaira, kuisa chisimbiso uye kucheka firimu, kuburitsa otomatiki chigadzirwa chekupedzisira kune conveyor. Kugona kwayo 1000-1500trays paawa, inokodzera chikafu chekugadzira fekitori zvinodiwa.

Muchina wese wakagadzirwa nesimbi isina tsvina 304 uye anodizing aruminiyamu, ive nechokwadi kuti unokwanisa kumhanya pane yakaipa chikafu fekitori nharaunda ine nyoro, chipfunga, mafuta, acidity uye munyu nezvimwe.

Uchishandisa emhando yepamusoro zvikamu zvemagetsi zvinotengeswa kunze kwenyika uye zvikamu zvepneumatic izvo zvinovimbisa kugadzikana kushanda kwenguva yakareba, kuderedza kumira uye kugadzirisa nguva.

1.Driven system: servo mota ine gearbox yetireyi molds inotsika ichimhanya, inogona kufamba yakazadzwa tireyi nekukurumidza asi inodzivirira zvinhu splash nekuti servo mota inogona kutanga nekumira zvakanaka, uye zvakare yakakwirira positioning kururama.

2. Empty tray loading function: inoshandisa spiral kupatsanura nekutsikirira tekinoroji iyo inogona kudzivirira kukuvara kwetireyi nekuremara, ine vacuum sucker inotungamira tireyi kupinda mukuumbwa kwayo.

3.Empty tireyi yekuona basa: inoshandisa photoelectric sensor kana optical fiber sensor kuti ione mold ine kana isina tireyi isina chinhu, inogona kudzivirira kukanganisa kuzadza, kuvhara uye kuvhara kana mold isina matireyi, kuderedza chigadzirwa tsvina uye nguva yekuchenesa muchina.

4. Quantitative kuzadza basa: akawanda-musoro akangwara akasanganiswa kuyera uye yekuzadza sisitimu inogamuchirwa kuita yakakwirira-chaiyo kuyera uye kuwanda kuzadza kune akasiyana akaumbwa zvinhu zvakasimba. Zviri nyore uye nekukurumidza kugadzirisa uye ine diki kukanganisa muhuremu hwegiramu. Uchishandisa servo drive material distributor, chaiyo positioning, diki kudzokorora chinzvimbo kukanganisa, kushanda kwakagadzikana

5.Vacuum gasi flushing system: inogadzira pombi yevacuum, mavharuvhu, mavharuvhu egasi, mavharuvhu ekuburitsa mhepo, vharafu inodzora vharafu, sensor sensor, vacuum chambers etc. inopomba mweya uye jekiseni gasi kuti iwedzere hupenyu hwesherufu.

6.Roll firimu sealing yekucheka basa: Iyo sisitimu ine otomatiki dhirowa remufirimu, nzvimbo yekudhinda firimu, tsvina yekuunganidza firimu uye thermostat yekuisa chisimbiso system, yekuisa chisimbiso inogona kumhanya nekukurumidza uye inowana pane yakadhindwa firimu nemazvo. Thermostat yekuisa chisimbiso yekucheka system inoshandisa Omron PID tembiricha controller uye sensor yemhando yepamusoro yekuisa chisimbiso.

7.Discharge system: inogadzira nekusimudza tireyi uye kudhonza hurongwa, ejection conveyor, iyo yakarongedzwa trays inosimudza uye kusundira kune conveyor nekukurumidza uye yakagadzikana.

8.Automation control system: inogadzira nePLC, Bata skrini, servo system, sensor, magineti valve, relays nezvimwe.

9.Pneumatic system: inogadzira nevharuvhu, mhepo sefa, mita, kudzvanya sensor, magineti valve, macylinders emhepo, silencer nezvimwe.

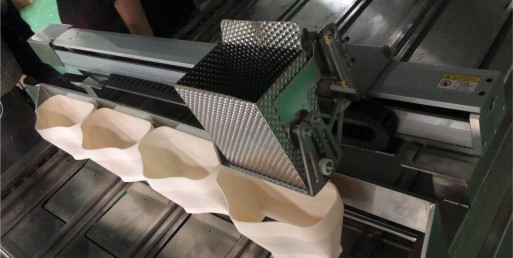

Vacuum gasi rekutsvaira yekuisa chisimbiso chekucheka mudziyo

Inoyerera chati yekurongedza

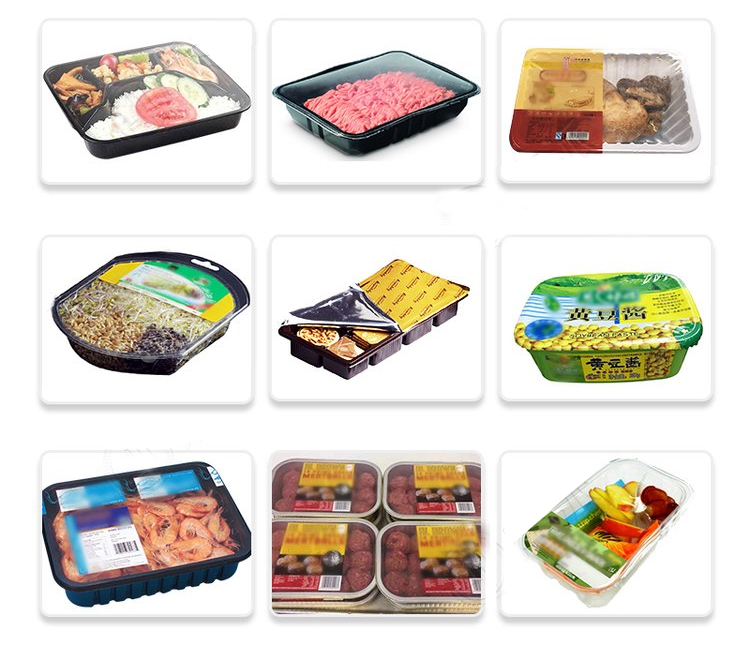

Inoshandiswa zvakanyanya kune matireyi ehukuru hwakasiyana uye maumbirwo. Izvi zvinotevera chikamu chekurongedza mhedzisiro show

Muchidimbu, sangano renguva refu rekutakura muchina rinomhanya pane zvine musoro uye zvesainzi manejimendi maitiro akagadzirwa nevatungamiriri vakangwara uye vakasiyana. Hutungamiri uye zvimiro zvesangano zvese zvinovimbisa kuti bhizinesi rinopa rakakwana uye remhando yepamusoro sevhisi yevatengi.

Vatengi vemuchina wekutakura tireyi vanobva kumabhizinesi mazhinji nenyika dzepasirese. Vasati vatanga kushanda nevagadziri, vamwe vavo vanogona kugara zviuru zvemakiromita kubva kuChina uye vasina ruzivo rwemusika weChina.

Kukwevera muvashandisi vakawanda uye vatengi, vagadziri veindasitiri vari kuramba vachigadzira hunhu hwayo kune yakakura huwandu hwemamiriro ekushandisa. Pamusoro pezvo, inogona kugadziridzwa kune vatengi uye ine dhizaini inonzwisisika, iyo yese inobatsira kukura mutengi uye kuvimbika.

MuChina, nguva yakajairika yekushanda maawa makumi mana kune vashandi vanoshanda nguva yakazara. MuSmart Weigh Packaging Machinery Co., Ltd., vashandi vazhinji vanoshanda vachiteera nerudzi urwu rwemutemo. Munguva yebasa ravo, mumwe nemumwe wavo anopira kutarisisa kwavo kuzere kubasa ravo kuti vape vatengi vane yepamusoro-yemhando Weigher uye isingakanganwike chiitiko chekubatana nesu.

Kushandiswa kwemaitiro eQC kwakakosha pamhando yechigadzirwa chekupedzisira, uye sangano rega rega rinoda dhipatimendi rakasimba reQC. tireyi yekurongedza muchina QC department yakazvipira kuenderera mberi nekuvandudzwa kwemhando uye inotarisa pane ISO Mitemo uye maitiro ekusimbisa hunhu. Mumamiriro ezvinhu aya, maitiro anogona kuenda zviri nyore, zvinobudirira, uye nemazvo. Yedu yakanaka certification ratio ndeye mhedzisiro yekuzvipira kwavo.

Nezve hunhu uye kushanda kwetireyi yekurongedza muchina, imhando yechigadzirwa chinogara chiri mufashoni uye chinopa vatengi mabhenefiti asina magumo. Inogona kuva shamwari inogara kwenguva refu yevanhu nekuti inovakwa kubva kune zvemhando yepamusoro zvinhu uye ine hupenyu hurefu.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved