Smart Weigh | Popular liquid filling equipment factory

Set up years ago, Smart Weigh is a professional manufacturer and also a supplier with strong capabilities in production, design, and R&D. liquid filling equipment Today, Smart Weigh ranks the top as a professional and experienced supplier in the industry. We can design, develop, manufacture, and sell different series of products on our own combining the efforts and wisdom of all our staff. Also, we are responsible for offering a wide range of services for customers including technical support and prompt Q&A services. You may discover more about our new product liquid filling equipment and our company by directly contacting us. has been focusing on the research, development and production of liquid filling equipment for many years, and has established good cooperative relations with well-known domestic and foreign counterparts. With strong technical strength and rich management experience, the liquid filling equipment produced is reliable in performance and high in quality. , energy saving and environmental protection, durable, enjoy a good reputation in the industry.

The machine is composed of granule filling head, chain plate conveyer belt and positioning device. It can complete automatic positioning, filling and measuring work of the bottle. Using servo (or step) motor and PLC touch screen, the operation is simple and the stability is high. It can be made up of a full set of filling line with the bottle cutting machine, the rotating cover machine and the labeling machine. Suitable for packing of powder and granule materials, such as powder, small granules medicine, veterinary medicine, glucose, spices, solid beverage, carbon powder, talcum powder, pesticide etc.. It can be installed on the basis of different materials, and can also produce two, three and four equipment according to the requirements of the packing speed.

※ Features

Factory price Gum Candy PET Jar Packing Machine Snack Food Granule Jar Filling Capping Labeling Machine

1.Seaming rollers are made of stainless steel with high hardness and never rusty with excellent sealing performance.

non rotation of can body in the process of sealing ,which avoids shift and scatter of product put well in the can.

1. Weighing range: 10-1500g 10-3000g

2. Weighing accuracy: 0.1-1.5g 0.2-2g 3. Max. filling speed: 60cans/min 4. Hopper capacity: 1.6L/2.5L 5. Control System: MCU 6. Touch screen: 7 inches 7. Power supply: AC220V 50/60Hz 8. Size: L1960*W4060*H3320mm9. Weight: 1000kg

10.Machine power: 3 kw(about)

For more information, please feel free to contact me.......

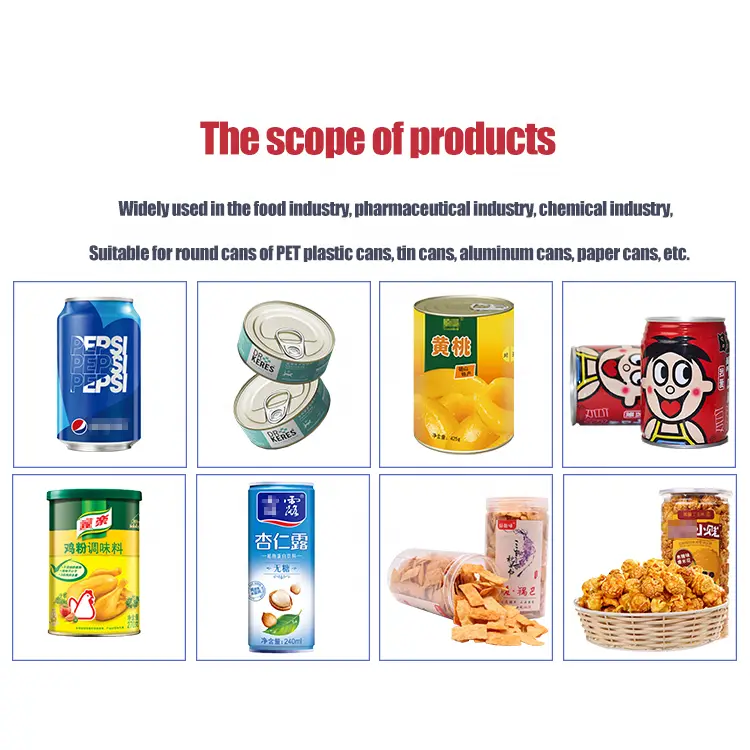

※ Application

Scope of application: Laundry gel beads, wolfberry, nuts and other granular quantitative weighing packaging;

Filling containers: bottles; plastic cans; glass cans; tinplate cans; cartons, etc.

※ Function

※ Product Certificate

Quick Link

Packing Machine