Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

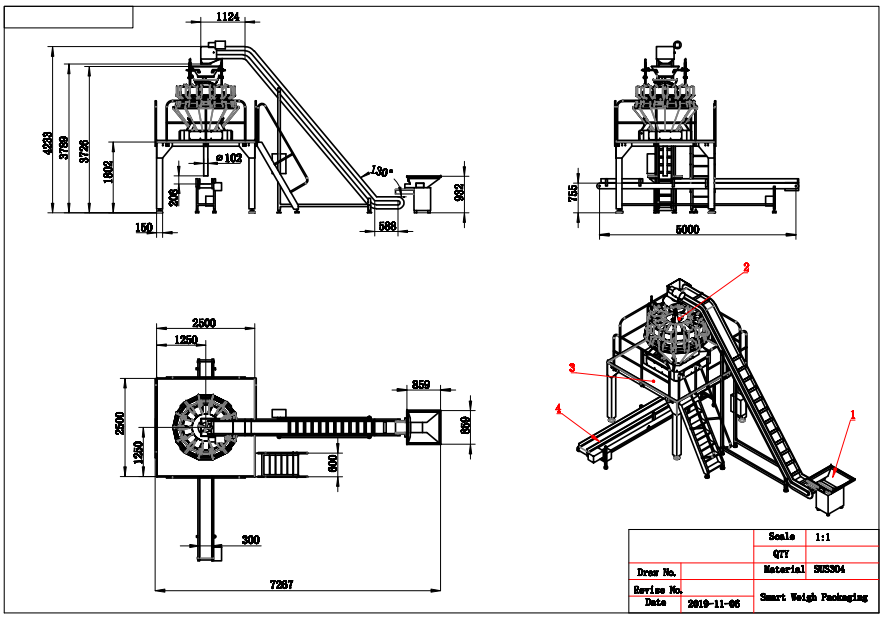

Why pick a screw weighing and packaging line that is semi-automatic?

Highly effective screw weighing and packing line from Smart Weigh helped a Colombian manufacturer of machinery cut production time and expenses and boost profit margins.

1. Wear resistant

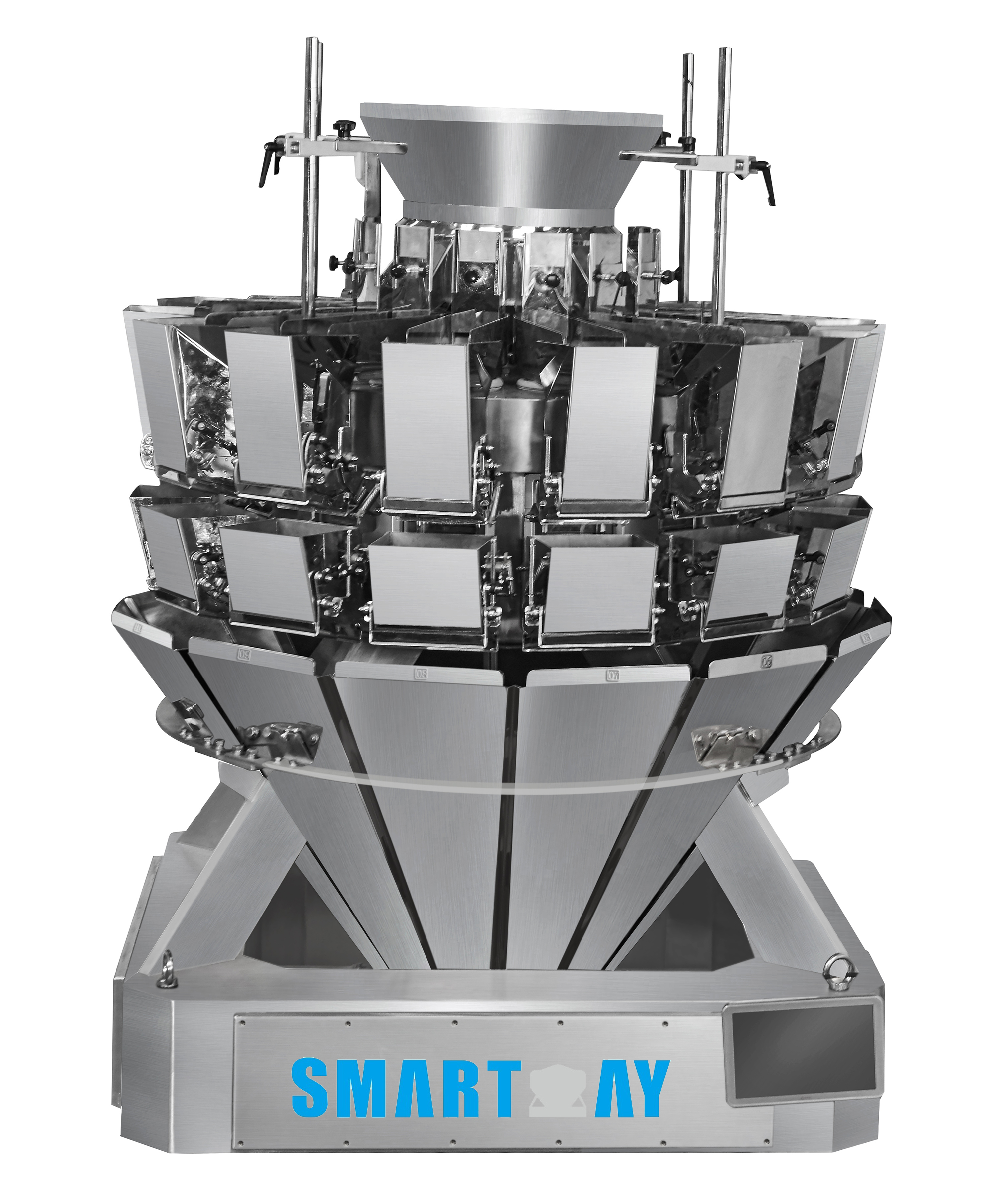

Because metal material like chips, screws, and nails have a high impact on weighers, Smart Weigh developed a stronger reinforced weigher to increase the weigher's resistance to deterioration.

2. Save labor

Initially, the firm had to hire 50 workers to physically weigh and pack screws, but by using the multi-head weighers that Smart Weigh offered, they were able to complete the task with just 10 personnel.

Only two personnel are needed to operate a single packing line thanks to the weighing and packaging system, which automatically weighs, feeds, and delivers the entire process. This greatly lowers labor expenses.

3. Flexible choice

Depending on the cost and labor force, you can alternatively select a fully or a semi-automatic box packing method. According to varied nail lengths and box sizes, you can select several models of weighing and packing machine.

1. Multihead weighers have good weighing efficiency and are sensitive.

2. Multi-head weighing machine made of SUS304 stainless steel that has strong impact resistance, a large hopper thickness, and good stability performance.

3. High precision, lower packing failure rates, less screw waste, and lower production costs.

4. Depending on the properties of various materials, different hoppers come in various sizes and types.

Widely employed in the chemical, pharmaceutical, and food industries, this weigher is appropriate for weighing products such as screws, nails, chips, tablets, and seeds.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425