Why is the multihead weigher more and more important in weighing and packaging?

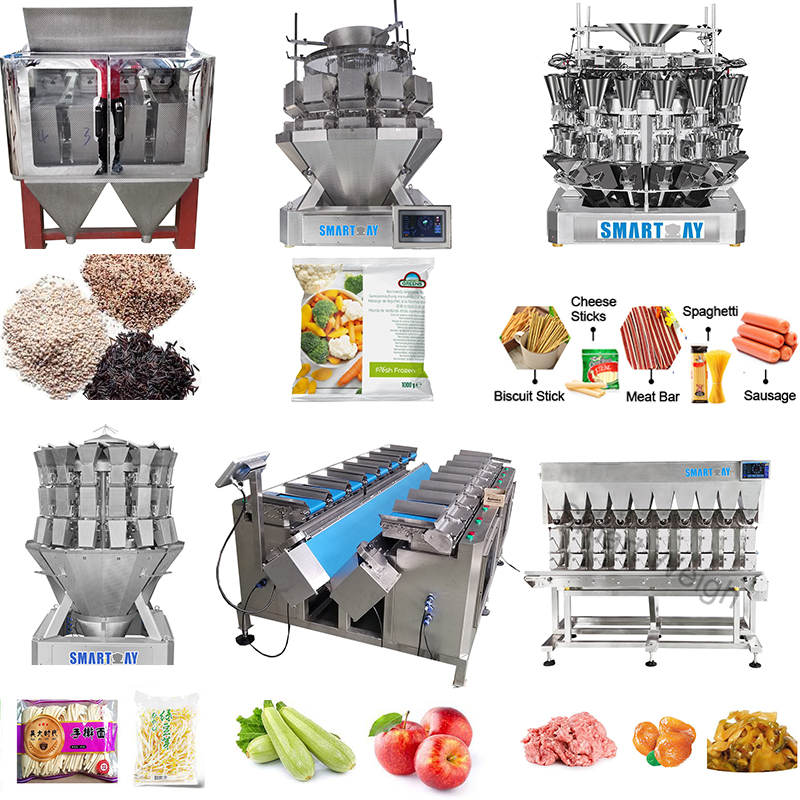

A multihead weigher is an automated system that weighs, sorts and counts products. The system consists of a feeder, a series of weighing modules and a controller.

The feeder is responsible for feeding the products to the system while the controller manages all aspects of weighing and sorting process. The weighing modules are responsible for measuring the weight of each product as it passes along the conveyor belt.

Multihead weighers are used in the industry to measure the weight of cereals and other grains.

The multihead weigher is a machine that weighs the cereal or grain that's being processed on a conveyor belt. The weight is determined by how many times the product passes under one of the weighing heads, which are mounted on arms that can move up and down.

Parts of multihead weigher

The multihead weigher is used in the cereal industry to weigh cereal grains, such as corn. There are usually two weighing heads mounted on arms that can move up and down. One of the larger belts moves through a pair of these heads so that each head only has to weigh a single portion of the grain, making it possible to measure the weight with greater accuracy.

The upper belt is connected to a wire which leads to the operator and is mounted on a vertical rod so that it can swing up and down as required. The lower belt is connected to the ground by means of a shackle through which passes one end of another wire leading back to the machine.

This invention is a safety device for use on excavating machines for the purpose of preventing the ground from caving in. The machine includes a large, vertical rod mounted on a shaft which is rotated by means of a motor. The large belt wraps around this rod, and the smaller belt wraps around this rod as well. As with all inventions, it is important to consider how it solves problems and benefits society

The large belt wraps around this rod, and the smaller belt wraps around this rod as well. As with all inventions, it is important to consider how it solves problems and benefits society.

Why Multihead Weighers are the Best Solution for Your Business?

Multihead weighers are the best solution for your business because they can provide you with the most accurate measurements. They are also used in a wide range of applications, from food to chemical manufacturing.

Some of the benefits of using multihead weighers include:

-Accuracy: Accurate weight measurements can be made in a wide range of applications and industries.

-Efficiency: Multihead weighers can save time and money by reducing the need for manual labor.

-Versatility: Multihead weighers offer versatility in both their application and design, making them an attractive option for many different kinds of businesses.

How to Choose the Right Multihead Weighing Machine for Your Industry?

The multihead weighing machine is a weighing system that has two or more scales. These scales are usually installed in the same frame and can be used for different purposes. In this article, we will discuss how to choose the right multihead weighing machine for your industry.

Multihead Weighing Machines are used by many industries, including food and beverage, chemicals, pharmaceuticals, and many more. The type of machine you need depends on the product you want to measure or weigh as well as the application you will use it for. For example, if you need to weigh small products quickly and accurately with a high throughput rate then a high speed scale is best suited for your needs.

If you are looking for a machine that can measure large products then an industrial scale would be more appropriate.

Choosing the right multihead weighing machine for your industry can be a daunting task. There are so many different types of machines with various features and price ranges that it might seem like an impossible task to find the best one. This article will walk you through the basics of what you need to know before purchasing a multihead weighing machine. .It is important to get the right multihead weighing machine for your business.-Industries that use tonnage machines are likely to require high capacity, large screens with a variety of options, and a demountable design for multiple applications.

A multi-head weigher, at its most basic level, weighs bulk items into smaller increments in accordance with the weights entered into its software. The bulk product is typically loaded into the scale through the infeed funnel at the top using a bucket elevator or an inclined conveyor.

How are combinations calculated in a multihead weigher?

A extremely precise load cell is included with each weigh hopper. The product weight in the weigh hopper will be determined by this load cell. The best combination of available weights needed to attain the intended goal weight will subsequently be determined by the processor in the multihead Weigher.

Author: Smartweigh–Multihead Weigher

Author: Smartweigh–Multihead Weigher Manufacturers

Author: Smartweigh–Linear Weigher

Author: Smartweigh–Linear Weigher Packing Machine

Author: Smartweigh–Multihead Weigher Packing Machine

Author: Smartweigh–Tray Denester

Author: Smartweigh–Clamshell Packing Machine

Author: Smartweigh–Combination Weigher

Author: Smartweigh–Doypack Packing Machine

Author: Smartweigh–Premade Bag Packing Machine

Author: Smartweigh–Rotary Packing Machine

Author: Smartweigh–Vertical Packaging Machine

Author: Smartweigh–VFFS Packing Machine

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine