Kusukela ngo-2012 - i-Smart Weight izibophezele ekusizeni amakhasimende ukwandisa umkhiqizo ngezindleko eziphansi.

Indlela Yokufaka Umshini Wokugcwalisa Ifomu Eliqondile: Umhlahlandlela Wochwepheshe Wabaqalayo

Imishini Yokugcwalisa Ifomu Eliqondile iguqula imisebenzi yokupakisha futhi ingagcwalisa amaphakethe angu-200 ngomzuzu. Le mishini iyindlela enhle yokuthuthukisa ukusebenza kahle embonini yokudla, iziphuzo, yezemithi, kanye neyokunakekela umuntu siqu. Ukusetha kudinga ukunakwa ngokucophelela emininingwaneni ngezinyathelo ezihlukile zokufakwa okufanele.

Ukutshalwa kwezimali kokuqala kungaba yinto enkulu. Ukufakwa kahle kuzokunikeza izinzuzo zesikhathi eside ngokusebenzisa ukusebenza kahle kokukhiqiza kanye nokulahlekelwa okuncane kwezinto ezibonakalayo. Le mishini eguquguqukayo isebenza ngezinto zokupakisha ezahlukene, kusukela ku-polyethylene kuya ku-polypropylene. Iphinde inikeze izindlela eziningi zokuvala ezigcina ubuqotho bephakheji.

Lesi sihloko sihlukanisa inqubo yokufaka ibe yizinyathelo ezilula. Ngisho nabaqalayo bangakwazi ukubhekana nalo msebenzi oyinkimbinkimbi futhi bathole okuningi emshinini wabo wokufaka uphawu oluqondile.

Uyini Umshini Wokugcwalisa Ifomu Eliqondile (i-VFFS)?

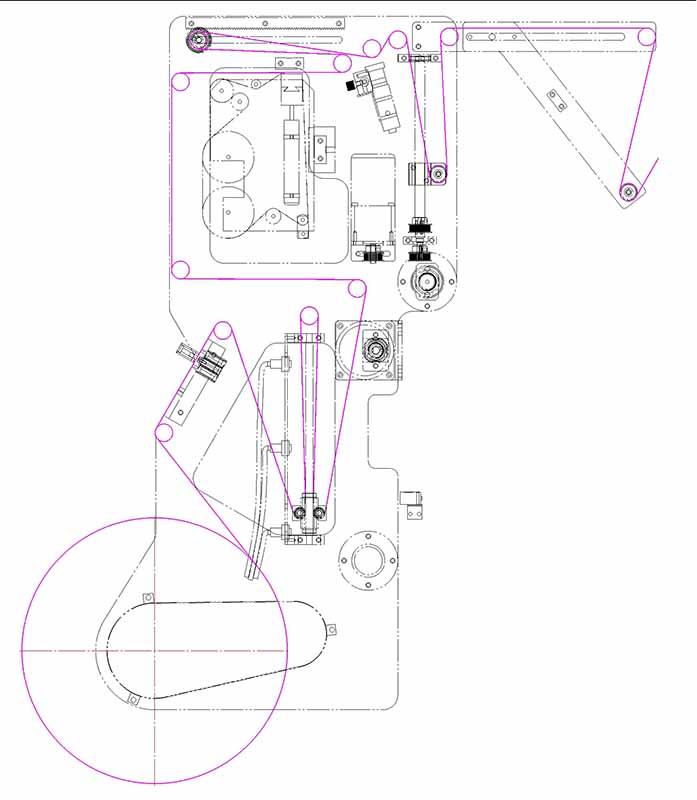

Umshini wokugcwalisa ifomu eliqondile (i-VFFS) uwuhlelo lokupakisha oluzenzakalelayo oludala, lugcwalise, futhi luvale izikhwama kusukela ku-roll eqhubekayo yefilimu. Umshini udala izikhwama zepulasitiki ezinomthamo wama-powder, uketshezi, ama-granule, kanye nezinto eziqinile.

Umshini uqala ngefilimu eyisicaba, ngokuvamile ephrintiwe ngaphambilini ngamalebula omkhiqizo. Umshini wenza le filimu ibe yipayipi, uvale ukuphela, ulinganise umkhiqizo, uvale phezulu, bese wenza ukuphela kwesikhwama esilandelayo. Imishini ishesha kakhulu futhi ingakhiqiza izikhwama ezingafika ku-200 ngomzuzu emugqeni we-duplex.

Imishini ye-VFFS ingavala amaphakheji ahlukahlukene, okuhlanganisa ipulasitiki, ifilimu/ifoyili yensimbi kanye nephepha. Izinhlelo eziningi zivala namaphakheji ngeshaja ye-nitrogen, okunikeza izimpahla isikhathi eside ngaphandle kwesidingo sezilondolozi zamakhemikhali.

Ukubaluleka Kokufakwa Okufanele Ukuze Kusebenze Kahle

Ikhwalithi yokufaka ithinta ikhwalithi yomkhiqizo womshini kanye nokusebenza kahle kwawo. Uhlelo lwe-VFFS olufakwe kahle lusiza amabhizinisi ukuhlangabezana nezidingo zamakhasimende kanye nokunciphisa imfucuza. Impumelelo yomshini incike ekusethweni okunembile kwezingxenye eziningana ezibalulekile:

● Izinhlelo zokuthutha amafilimu

● Izindlela zokuvala

● Amayunithi okusabalalisa imikhiqizo

● Izinhlelo zokulawula izinga lokushisa

Abasebenzi abaqeqeshwe kahle bangasebenzisa imishini ngempumelelo, balungise izinkinga ngokushesha, futhi balondoloze ikhwalithi yomkhiqizo ehambisanayo. Ukusetha okufanele kuzonikeza izimo zokusebenza ezinhle kakhulu kuzo zonke izingxenye zomshini futhi kunciphise ukuwohloka okungalindelekile okungabiza kakhulu.

Amathuluzi Abalulekile Nezidingo Zokuphepha

Impumelelo ekufakweni komshini wokugcwalisa ifomu eliqondile iqala ngokulungiselela okufanele. Siqoqe amathuluzi futhi sabeka izinyathelo zokuphepha ezibalulekile.

Uhlu lokuhlola amathuluzi adingekayo

Inqubo yokufaka idinga amathuluzi alula okusebenza kanye nemishini ekhethekile. Kumelwe ube nezibuko zokuphepha kanye namagilavu angashisi. Indawo yokusebenza idinga ukuxhumeka okufanele kwamandla kanye nezinhlelo zomoya ezicindezelwe ukuze umshini usebenze kahle.

Uhlu lwemishini yokuphepha

Ukuphepha kubalulekile kuyo yonke inqubo yokufaka. Ngakho-ke, udinga le mishini yokuzivikela:

● Izindlela zokuma eziphuthumayo zokuvala umshini ngokushesha

● Imishini yokuzivikela yomuntu siqu (PPE) okuhlanganisa namagilavu angashisi

● Izibuko zokuphepha zokuvikela amehlo akho

● Amadivayisi okukhiya ukuze ahlukanise ugesi

Iziqondiso zokulungiselela indawo yokusebenza

Udinga ukulungiselela indawo yokufaka ngokucophelela ukuqinisekisa ukuthi umshini usebenza kahle futhi ngokuphephile. Isikhala kufanele silingane nomshini futhi sinikeze isikhala esanele sokulungisa. Indawo yakho yokusebenza idinga:

● Indawo ehlanzekile engenazo izingozi

● Ukuphakama okwanele kwesistimu yomshini

● Ukuxhumeka kukagesi okufanele

● Izinhlelo zokuhambisa umoya ezicindezelwe

● Izinhlelo zokulawula izinga lokushisa nomswakama

Abasebenzi abafanelekayo kuphela okufanele baphathe ukuxhumeka kukagesi futhi bahambise umshini ukuze bagweme umonakalo noma ukulimala. Indawo yokufaka idinga izimo zemvelo ezifanele ngoba amazinga okushisa aphezulu angathinta indlela umshini osebenza kahle ngayo.

Ukuhlela Ngaphambi Kokufaka

Ukuphumelela okukhulu ekufakweni komshini wokupakisha we-VFFS kuqala ngokulungiswa kahle kwendawo kanye nokuhlolwa kwezinsizakusebenza. Sihlole indawo yokusebenza ukuqinisekisa ukufakwa nokusebenza komshini okungcono kakhulu.

Ukuhlolwa kwesiza

Indawo yokufaka idinga ukubheka izidingo zokusebenza zamanje nezesikhathi esizayo. Isithombe esigcwele sendawo sibheka izidingo zesikhala saphansi, izici ze-ergonomic, kanye namaphethini okugeleza kwezinto. Indawo yokusebenza kumele ivumelane nobukhulu bomshini futhi ishiye isikhala sobubanzi obukhulu bokugoqa obungu-450 mm kanye nobubanzi obungu-645 mm.

Ukuqinisekiswa kokunikezwa kwamandla nomoya

Umshini udinga nje ukuqinisekiswa kwamandla athile ukuze usebenze kahle. Amamodeli omshini anemininingwane kagesi:

● Ukunikezwa kwamandla kagesi okungu-220V okujwayelekile, isigaba esisodwa, okungu-50 noma okungu-60 Hz

● Uma impuphu yakho yendawo ingu-110V noma u-480V, sicela utshele umhlinzeki wakho ngaphambi koku-oda.

Ukunikezwa kwamandla okuzinzile ngaphakathi kwebanga likagesi elibekiwe kuyisici esibalulekile ekusebenzeni okuphezulu. Uhlelo lokunikezwa komoya ludinga ukunakwa okufanayo, ngemishini evame ukusebenza ku-85-120 PSI. Ukunikezwa komoya ohlanzekile nowomile kuzovikela uhlelo lomoya futhi kugcine ukumbozwa kwewaranti.

Amaqembu kumele avikele yonke imigqa yokuhambisa umoya kahle ukuze agweme izingozi ezivela kumapayipi axegayo. Ukuhlolwa kwesihlungi somoya wokuhambisa kusiza ukugcina uhlelo lomoya lomshini wokupakisha lusebenza kahle.

Inqubo Yokufaka Isinyathelo Ngesinyathelo

Impumelelo ekufakweni komshini we-VFFS iqala ngokunaka imininingwane.

Ukukhipha impahla kanye nokuhlola impahla

Ithimba kumele likhiphe amabhokisi amahlanu ezinkuni aqukethe ilifti, umshini wokulinganisa we-elekthronikhi, umshini wokugcwalisa amafomu oqondile, amabhuleki etafula lokusebenzela, kanye nomshini wokuhambisa impahla. Ukuhlolwa okuphelele kwazo zonke izingxenye kuzonikeza isithombe esicacile sokuthi akukho lutho olulimele ngesikhathi sokuthunyelwa.

Uchungechunge lokuhlanganiswa kwezingxenye

Ukuhlanganiswa kulandela izinyathelo ezithile eziqala ngokubeka iyunithi eyinhloko ye-VFFS. Ithebula lokusebenza libekwa phezu komshini futhi lidinga ukuhlelwa nge-electronic weigher. Kumelwe ubeke imbobo yokukhipha amanzi ngqo maphakathi nepayipi langaphambili lesikhwama ukuze uthole ukusebenza okuhle kakhulu.

Ukuxhumanisa izintambo kanye nokuxhumeka

Izinqubo zokuphepha zidlala indima ebalulekile ekusethweni kukagesi. Umshini udinga nje ukuxhumana kwamandla okuzinzile phakathi kuka-208-240 VAC. Ukufakwa okuphephile kwamapayipi omoya namavalvu e-solenoid kuvimbela izimo eziyingozi ekuxhumaneni okuxekethile.

Inqubo yokulayisha ifilimu

Abasebenzi baqala ukulayisha ifilimu ngokukhulula umoya kusuka ku-shaft ngemuva komshini wokupakisha we-VFFS. I-roll yefilimu yokupakisha ifakwa ngokulandelayo, igxile kahle ku-shaft. Ngemva komdwebo ojikelezayo, ifilimu idlula emshinini bese iphela esikhwameni esingaphansi kwe-sealer evundlile.

Ukuhlolwa Kokuqala Nokulinganisa

Izinqubo zokuhlola zimelela isigaba sokugcina esibucayi sokufakwa komshini wokupakisha we-VFFS. Indlela ehlelekile izonikeza ukusebenza okuhle kakhulu futhi ivimbele izinkinga zokusebenza.

Ukuhlolwa kokusebenza okuyisisekelo

Ukuhlolwa okuphelele ngaphandle komkhiqizo kuqinisekisa ukuthi umshini usebenza kanjani. Abasebenzi kumele bangene ekunyakazeni kwenqola yefilimu futhi bahlole zonke izixhumanisi zezintambo. Iyunithi yokuvala eqondile idinga ukuhlolwa ngokucophelela ukuqinisekisa ukuma kwayo okuhambisanayo nepayipi yokwakha.

Ukulungiswa kwesivinini

Ukulinganiswa kwesivinini okufanele kudinga ukunakwa okunembile kobubanzi besikhwama kanye nemingcele yesikhala sekhanda. Umshini usebenza kahle kakhulu ngezilungiselelo ezifanele zokuqina kwefilimu kanye nemingcele yokuvala. Akungabazeki ukuthi ulawula ukuphathwa kwefilimu njengento ebalulekile njengoba amafilimu amakhulu adinga isikhathi eside sokuhlala ukuze kufakwe izivalo ezifanele.

Ukuhlolwa kokulungiswa kwefilimu

Ukuqinisekiswa kokulungiswa kwefilimu kuhlanganisa izindawo eziningana zokuhlola ezibalulekile:

● Ukubeka ifilimu phakathi nendawo ku-spindle

● Ukubekwa okuhambisanayo kwamazinga abagijimi nabadansi

● Ukusethwa okufanele kwamabhande okudonsa

● Ukusebenza kokulandelela ifilimu ezenzakalelayo

Naphezu kwalokho, abaqhubi kumele bagcine umehluko ofanele phakathi kophawu lweso nombala wangemuva ukuze bafinyelele ukubhaliswa okunembile. Inzwa yeso-nesithombe idinga indawo eqondile ukuze ithole izimpawu zokubhalisa futhi idale ubude besikhwama obuhambisanayo. Ukuhlolwa njalo kwalezi zinhlaka kusiza ekugcineni ukusebenza kahle komshini.

Izinkinga Ezivamile Zokufaka Nezixazululo

Ukufakwa kahle komshini wokupakisha we-VFFS kubalulekile ukuze kusebenze kahle. Ngezansi kunamaphutha avamile okufakwa kanye namathiphu okugwema lokhu:

Inkinga | Imbangela Engaba Khona | Isixazululo |

Umshini awuqali | Amandla awaxhunyiwe kahle | Hlola umthombo wamandla kanye nezintambo |

Ukungahambisani kahle kwefilimu | Ukufakwa kwefilimu okungalungile | Lungisa indlela yefilimu kanye nokungezwani |

Izikhwama azivalwa kahle | Izilungiselelo zokushisa azilungile | Lungisa izinga lokushisa le-sealer |

Isikali asikhiphi | Ikhebula lesignali alixhunyiwe | Hlola izilungiselelo zezintambo kanye namandla |

Isisindo asinembile | Kudingeka ukulinganisa | Linganisa kabusha i-weigher hopper |

I-Conveyor ayihambi | Ikhebula lesignali alixhunyiwe | Hlola izilungiselelo zezintambo kanye namandla |

Ukufaka umshini wokupakisha we-VFFS ngendlela efanele kubalulekile ekufezeni ukupakisha okuhlala njalo nokusezingeni eliphezulu. Ngokugwema la maphutha avamile, amabhizinisi angathuthukisa ukusebenza kahle, anciphise isikhathi sokungasebenzi, futhi andise isikhathi eside somshini. Ukugcinwa njalo nokuqeqeshwa okufanele kwabaqhubi kuqinisekisa ukusebenza kahle kakhulu.

Kungani Kufanele Ukhethe Iphakethe Elihlakaniphile Lokukala Isisindo Semishini Ye-VFFS?

I-Smart Weigh Pack ingumkhiqizi owaziwayo womhlaba wonke wemishini ye-Vertical Form Fill Sealing (VFFS), ehlinzeka ngezixazululo ezisheshayo, ezinembile, nezithembekile zokupakisha. Njengoba sineminyaka engaphezu kweyishumi yesipiliyoni, singochwepheshe ezinhlelweni zokulinganisa nokupakisha okuzenzakalelayo zezimboni ezahlukahlukene okuhlanganisa ukudla, izidakamizwa, kanye nehadiwe.

Imishini yethu yokugcwalisa ifomu eqondile yenzelwe ukusebenza kahle kakhulu kusetshenziswa ubuchwepheshe bamuva, iqinisekisa ukuvala ngokulinganayo, ukumosheka kwempahla okuphansi, kanye nokusetshenziswa okulula. Singanikeza izixazululo zezidingo ezahlukene zezimpahla ezahlukene: ama-granule, impuphu, uketshezi, noma ukudla okuqinile. Ngethimba lonjiniyela abangaphezu kuka-20 kanye nokusekela okubanzi kwamazwe ngamazwe, ukufakwa okubushelelezi, ukuqeqeshwa, kanye nokuthengisa ngemuva kokuthengisa kuqinisekisiwe.

Ngekhwalithi yethu, inani lemali yethu, kanye nokuzibophezela ekusunguleni izinto ezintsha emaphaketheni ethu, siyisisombululo esingcono kakhulu sezinkampani ezinesifiso sokukhulisa ukusebenza kwazo kokupakisha kanye nokukhiqiza. Vumela i-Smart Weigh Pack ibe yisisombululo sakho semishini ye-VFFS ethembekile, esebenza kahle kakhulu eyenzelwe ngqo izidingo zakho.

Isiphetho

Ukufakwa komshini we-VFFS kubalulekile ekufinyeleleni ukusebenza kahle kokupakisha kanye nekhwalithi yomkhiqizo. Isinyathelo ngasinye sibalulekile—kusukela ekuhloleni indawo kuya ekulinganisweni kokugcina. Lezi zinyathelo zizokunikeza ukusebenza komshini okuphumelelayo. Izinqubo zokuphepha ezifanele, amathuluzi, kanye nokuhlanganiswa okunembile kusebenza ndawonye ukwakha ukusebenza okuthembekile. Udinga ukunaka izidingo zamandla, imininingwane yokunikezwa komoya, kanye nokubekwa kwefilimu. Lokhu kuvimbela izinkinga futhi kwandisa umkhiqizo wakho.

Ukuhlola nokulinganisa yizinyathelo zokugcina ezibalulekile ezibonisa ukuthi umshini wakho usebenza kahle kangakanani. Kufanele uhlole ukucindezeleka kwefilimu, izilungiselelo zokuvala, kanye nokulungiswa kwesivinini njalo. Lokhu kunikeza ikhwalithi yephakheji ehambisanayo futhi kunciphisa izinto ezilahliwe.

Abanikazi bamabhizinisi abahlakaniphile abadinga usizo lochwepheshe ngokusetha umshini wabo wokupakisha we-VFFS bangathola ukwesekwa okuphelele ku-smartweighpack.com. Lezi zinyathelo zokufaka kanye nokugcinwa okufanele kuzosiza imisebenzi yokupakisha ukuthi ifinyelele imigomo yokukhiqiza. Uzogcina amazinga okuphepha ephezulu futhi wenze izinqubo zibe lula ngasikhathi sinye.

I-Smart Weight ingumholi womhlaba wonke ezinhlelweni zokupakisha ezinesisindo esinembile kakhulu nezihlanganisiwe, ethenjwa amakhasimende angaphezu kwe-1,000 kanye nemigqa yokupakisha engaphezu kwe-2,000 emhlabeni jikelele. Ngokusekelwa kwendawo e- Indonesia, eYurophu, e-USA nase-UAE , sinikeza izixazululo zomugqa wokupakisha we-turnkey kusukela ekuphakeleni kuya ekufakeni ama-pallet.

Isixhumanisi Esisheshayo

Umshini Wokupakisha