Kusukela ngo-2012 - I-Smart Weight izibophezele ekusizeni amakhasimende ukwandisa umkhiqizo ngezindleko eziphansi. Xhumana nathi Manje!

Okufanele Ukubheke Lapho Ukhetha Umshini Wokupakisha Ojikelezayo Womugqa Wakho Wokukhiqiza

Isingeniso

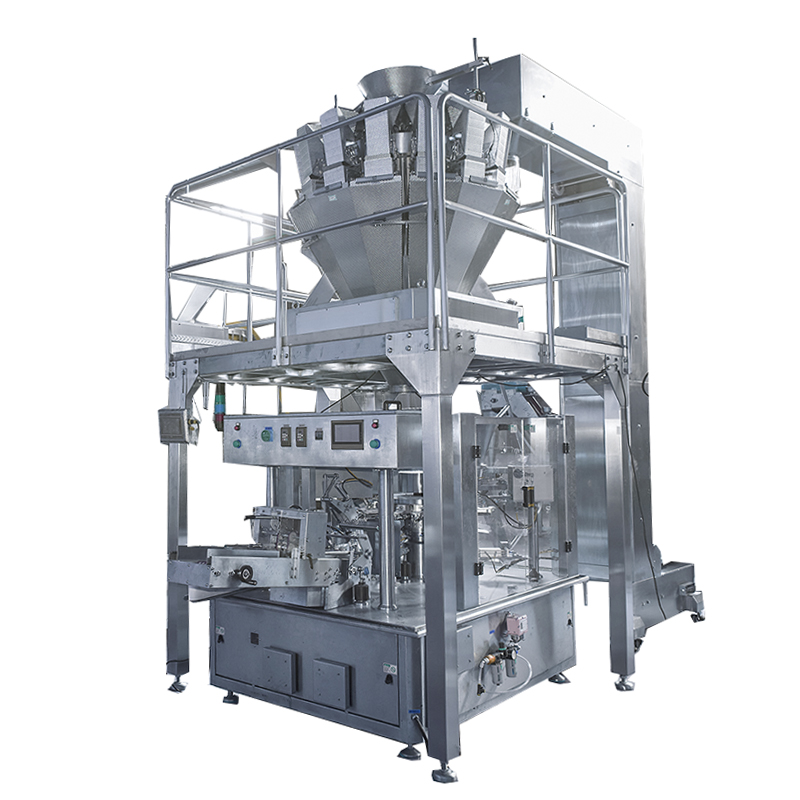

Umshini wokupakisha ojikelezayo uwuhlelo oluzenzakalelayo oluthuthukisa ukupakisha okusheshayo kwemikhiqizo efana nophuphu, uketshezi, kanye ne-granule. Le mishini isebenza nge-turret ejikelezayo eneziteshi eziningi ezenza imisebenzi efana nokuthatha izikhwama, ukuvula, ukugcwalisa, ukuvala, kanye nokuhlanza i-nitrogen ngokuvumelana. Zisetshenziswa kabanzi kuzo zonke izimboni ezifana nokudla, imithi, kanye nezimonyo ngenxa yokusebenza kahle kwazo kanye nokuguquguquka kwazo.

Uma ukhetha umshini wokupakisha ojikelezayo, cabanga ngezinto ezifana nokukhiqiza, ukuhambisana kwesikhwama, kanye nokunemba kokuvala. Kubalulekile futhi ukuhlola uhlelo lokugcwalisa—kungakhathaliseki ukuthi luyi-volumetric, i-auger, noma i-multi-head weiger—futhi uqinisekise ukuthi lusekela izinhlobo zesikhwama ezidingekayo, njengezikhwama ezimile noma eziziphu.

Izici ezifana nokushintsha okulula, amakhono e-CIP (Clean-in-Place), kanye nokuhlanganiswa okubushelelezi neminye imishini kungathuthukisa ukusebenza kahle kokukhiqiza. Ake sixoxe ngezidingo zokukhiqiza zebhizinisi lakho.

Izidingo Zakho Zokukhiqiza

Imishini yokupakisha ejikelezayo kufanele ivumelane nesilinganiso sakho sokukhiqiza kanye nemigomo. Thola ukuthi umsebenzi wakho uhilela ukupakisha okusheshayo noma ukugijima kweqembu elincane, njengoba amamodeli emishini ahlukene—njenge-simplex noma i-duplex—enikeza amazinga ahlukahlukene okusebenza kanye nokuguquguquka. Lokhu kuhlola kuqinisekisa ukusebenza kahle kwemishini kanye nokusebenza kahle kwezindleko.

● Izidingo Zesivinini Sokukhiqiza kanye Nomthamo

Umshini wokupakisha izikhwama ezijikelezayo ozenzakalelayo uphumelela kakhulu ekusebenzeni okusheshayo nokuqhubekayo, ngesivinini esifinyelela ezikhwameni ezingu-80 ngomzuzu kuye ngohlobo lomkhiqizo kanye nohlobo lwawo. Imishini efana namamodeli e-duplex yenzelwe ukukhiqizwa okuphezulu, okwenza ibe yindawo efanele amabhizinisi adinga ukwenziwa okusheshayo ngaphandle kokubeka engcupheni ukunemba.

● Uhlobo Lomkhiqizo Nesitayela Sokupakisha

Ukuguquguquka kwemishini yokupakisha izikhwama ezijikelezayo ngokuzenzakalelayo kuyivumela ukuthi iphathe uketshezi, impuphu, noma izinto eziqinile kalula. Isekela izitayela ezahlukene zokupakisha, kufaka phakathi izikhwama ezimile, ezisicaba, neziziphu, ezihlangabezana nezidingo zezimboni ezahlukahlukene, kusukela ekudleni kuya kwezemithi.

● Amakhono Okuphatha Izinto

Umshini wokupakisha izikhwama zesimanje ojikelezayo uyakwazi ukuhlanganisa umshini wokuphatha izinto osezingeni eliphezulu, njengesikali esinamakhanda amaningi kanye nesigcwalisi se-auger, okuqinisekisa ukunemba okuqhubekayo. Ngaphezu kwalokho, izici ezifana nokutholwa kokuba khona kwesikhwama zivimbela imfucuza yezinto ngokumisa inqubo uma isikhwama singekho, okuthuthukisa ukusebenza kahle kokukhiqiza.

Ikhwalithi Nokunemba Kokupakisha

Ikhwalithi yokupakisha ithonya ngqo ubuqotho bomkhiqizo kanye nokungaguquguquki kulo lonke ukukhiqizwa. Ukugcwalisa nokuvala ngokunembile kuvimbela ukugcwalisa okungaphelele, ukuchitheka, noma ukungcola, okubalulekile ekwanelisekeni kwamakhasimende kanye nokuhambisana nemithetho. Imishini yokupakisha ejikelezayo ivelele ngekhono layo lokugcwalisa nokuvala imikhiqizo ngokunembile ngesivinini esikhulu.

◆ Ukuqinisekisa Ukuvala Nokugcwalisa

Ukunemba kokuvala kuqinisekisa ukuthi umkhiqizo uhlala uvikelekile ezicini zemvelo njengomoya kanye nomswakama. Imishini ejikelezayo enobuchwepheshe obuthuthukisiwe bokuvala, njengezinhloko zokuvala ezilawulwa amazinga okushisa, idala izivalo ezingangeni moya ukuze kugcinwe ikhwalithi futhi kuncishiswe imfucuza. Ukunemba kokugcwalisa nakho kubalulekile; isibonelo, ukulinganisa okunembile kunciphisa ukungafani kobuningi bomkhiqizo, okubaluleke kakhulu ezintweni ezifana nophuphu, uwoyela, noma uketshezi ukuze kugcinwe ukufana kuzo zonke izinhlobo zokupakisha.

◆ Umthelela Ekuphileni Kweshelufu Lomkhiqizo Nokusha Kwawo

Iphakheji evalwe kahle ibalulekile ekwandiseni isikhathi sokuphila komkhiqizo ngokunciphisa ukuchayeka ku-oxygen kanye nomswakama, okungaholela ekonakalisweni. Imishini ejikelezayo eyenzelwe ukuvala i-vacuum ingabambezela kakhulu ukukhula kwebhaktheriya kanye nokubola, igcine ukusha komkhiqizo isikhathi eside. Leli khono lizuzisa kakhulu ukudla, izimonyo, kanye nemikhiqizo yemithi, lapho ukusha kuyinto eza kuqala ngesikhathi sokugcina nokusabalalisa.

Izici Zokuzenzakalela

Ukuzenzakalela emshinini wokugcwalisa izikhwama ezijikelezayo kuthuthukisa ukusebenza kahle, ukunemba, kanye nokukhipha, okwenza kube kubalulekile emigqeni yokukhiqiza efuna umkhiqizo ophezulu. Izinhlelo zesimanje zihlanganisa ubuchwepheshe obuthuthukisiwe njengokunyakaza okuqhubekayo okujikelezayo, okuqeda isikhathi sokungasebenzi futhi kuthuthukise ukuhambisana kokusebenza.

✔ Isixhumanisi Esisebenziseka Kahle Nokulawula

Isici esibalulekile semishini yokupakisha ezenzakalelayo yi-interface yayo enembile. Le mishini yakhelwe ngamaphaneli okulawula asebenziseka kalula, ngokuvamile afaka izikrini zokuthinta kanye nezilungiselelo ezingenziwa ngezifiso. Lokhu kwenza kube lula kubasebenzisi ukulungisa amapharamitha ngokushesha, kunciphisa ijika lokufunda kanye namaphutha okusebenza angaba khona.

✔ Izinga Lokwenza Izinto Ngokuzenzakalelayo

Imishini yokupakisha ejikelezayo iyahlukahluka emazingeni okuzenzakalelayo, kusukela ezinhlelweni ezizenzakalelayo kancane kuya emigqeni ezenzakalelayo ngokuphelele. Amamodeli azenzakalelayo ngokuphelele enza ngcono umkhiqizo ngokuhlanganiswa kalula nama-conveyor neminye imishini, okunciphisa ukungenelela kwabantu kuyo yonke inqubo. Imishini enjalo iwusizo ikakhulukazi ezimbonini ezisebenzisa umthamo omkhulu.

Izidingo Zezinyathelo Zomshini Nesikhala

Usayizi obonakalayo womshini wokupakisha isikhwama esijikelezayo uthinta indlela ofanelana kahle ngayo nendawo yakho yokukhiqiza. Abakhiqizi kumele futhi bahlole imiklamo ye-modular noma eyenziwe ngezifiso ukuqinisekisa ukuguquguquka kanye nokukhula kwesikhathi esizayo.

● Ubukhulu Bomzimba Bomshini

Usayizi womshini wokugcwalisa isikhwama esijikelezayo uthinta ngqo ukuhlelwa kwephansi lokukhiqiza. Amamodeli amancane avumela ukuhlanganiswa okulula emigqeni ekhona ngaphandle kokuphazamisa ukuhamba komsebenzi, kuyilapho imishini emikhulu ingadinga ukwakheka ngokwezifiso.

● Imiklamo Eyimodeli noma Engenziwa Ngokwezifiso

Imiklamo ye-Modular inikeza ukuguquguquka ngokuvumela abakhiqizi ukuthi bavumelanise umshini nemikhiqizo ehlukene noma izidingo zokupakisha ngokuphazamiseka okuncane. Lokhu kuvumelana nezimo kwenza kube lula ukwethula imikhiqizo emisha ngaphandle kokushintsha lonke uhlelo, okuqinisekisa ukuguquguquka nokusebenza kahle ngezidingo zokukhiqiza ezishintshayo.

Ukuphathwa Kwesivinini Nokuphumula

Ukuphatha ijubane kanye nesikhathi sokungasebenzi kubalulekile ekugcineni ukusebenza kahle. Imishini ene-CPM ephezulu (imijikelezo ngomzuzu) kanye nokushintshashintsha okusheshayo kusiza ekunciphiseni ukuphazamiseka nokugcina umkhiqizo uhamba kahle.

◆ Isivinini Somshini

Isivinini sokusebenza, esivame ukulinganiswa esikhwameni ngomzuzu (PPM), siyisibonakaliso esibalulekile sokusebenza. Amazinga aphezulu e-PPM abalulekile ekusebenzeni okuphezulu, kodwa ukugcina ukunemba ngesivinini esinjalo kungaba yinselele. Eminye imishini ifinyelela isivinini esifinyelela ku-45 PPM, ishaya ibhalansi phakathi kwesivinini nekhwalithi ukuze ihlangabezane nemigomo yokukhiqiza ngempumelelo.

◆ Izikhathi Zokushintsha Nokuguquguquka

Ukushintsha okusheshayo nokusebenza kahle kubalulekile ekunciphiseni isikhathi sokungasebenzi, ikakhulukazi lapho kushintsha izinhlobo zomkhiqizo noma amafomethi okupakisha. Imishini emisha isekela ukushintsha okuhlelekile ngezinhlelo ezenzakalelayo kanye nezixhumi ezinembile zomshini womuntu (ama-HMI), okunciphisa kakhulu ukulungiswa ngesandla.

Ukuhambisana Nezindinganiso Zemboni

Imishini yokupakisha ejikelezayo kumele ilandele imithetho eqinile yemboni ukuqinisekisa ukuphepha, ukusebenza kahle, kanye nokusimama. Ukuthobela amazinga okudla, kagesi, kanye nemvelo kubalulekile ukuze kuhlangatshezwane nezidingo zomthetho nezokusebenza.

▼ Izindinganiso Zokuphepha Kokudla kanye Nezitifiketi (i-HACCP, i-FDA, i-GMP)

Imishini yokupakisha esetshenziselwa imikhiqizo yokudla kumele ivumelane nezindinganiso ezifana ne-HACCP, iziqondiso ze-FDA, kanye ne-Good Manufacturing Practices (GMP). Lezi zinhlaka ziqinisekisa ukuthi izindawo zokukhiqiza zinciphisa izingozi zokungcola futhi zigcina ikhwalithi yomkhiqizo kuyo yonke inqubo, okubalulekile ekuvunyelweni komthetho kanye nokwethenjwa kwamakhasimende.

▼ Ukuthobela Ukuphepha Kukagesi Nokwemishini (Ukumaka kwe-CE, Amazinga e-ISO)

Imishini ejikelezayo kudingeka ihlangabezane nezidingo zokumaka ze-ISO kanye ne-CE ukuqinisekisa ukuphepha nokusebenza kanye nokuthembeka. Lezi zitifiketi zihlanganisa ukuphepha kukagesi, okwemishini, kanye nokusebenza, okunciphisa izingozi ngesikhathi sokusetshenziswa nokugcinwa komshini.

▼ Izindinganiso Zokusebenzisa Kahle Emvelweni Namandla

Imishini yesimanje ejikelezayo kumele ihlangabezane nezindinganiso zemvelo zokusebenzisa kahle amandla kanye nokunciphisa imfucuza. Izitifiketi ezifana ne-FSSC 22000 zigcizelela ukusimama kwezinqubo zokupakisha, zikhuthaza ukusetshenziswa kahle kwezinto zokwakha kanye namandla ngenkathi kugcinwa ukuphepha kokudla.

Isiphetho

Uma ukhetha umshini wokupakisha ojikelezayo womugqa wakho wokukhiqiza, kubalulekile ukuhlola izici ezifana nesivinini, ukunemba, kanye nokuhambisana nezindinganiso zemboni. Imishini efana nomshini wokupakisha ojikelezayo we-SW-8-200 oneziteshi ezingu-8 iqinisekisa ukugcwalisa nokuvala okuqhubekayo ngenkathi ihlangabezana nezidingo zomthetho zemikhakha efana nokudla kanye nemithi. Le mishini yenza kube lula ukusebenza, ithuthukise ukusebenza kahle kanye nekhwalithi yomkhiqizo.

Ukuze uthole imiphumela emihle, khetha umenzi odumile njengo-Smart Weigh onikeza izixazululo ezithuthukisiwe njengomshini wokupakisha ojikelezayo ozenzakalelayo we-SW-8-200 . Ngokugxila kwabo ekwakhiweni okwenziwe ngezifiso kanye nokusebenza okonga amandla, imishini ye-Smart Weigh Pack yenzelwe ukuhlangabezana nezidingo eziningi zokupakisha ngenkathi igcina amazinga aphezulu okusebenza kanye nokusimama.

I-Smart Weight ingumholi womhlaba wonke ezinhlelweni zokupakisha ezinesisindo esinembile kakhulu nezihlanganisiwe, ethenjwa amakhasimende angaphezu kwe-1,000 kanye nemigqa yokupakisha engaphezu kwe-2,000 emhlabeni jikelele. Ngokusekelwa kwendawo e- Indonesia, eYurophu, e-USA nase-UAE , sinikeza izixazululo zomugqa wokupakisha we-turnkey kusukela ekuphakeleni kuya ekufakeni ama-pallet.

Isixhumanisi Esisheshayo

Umshini Wokupakisha